10 Tips You Need to Keep in Mind Before You Buy a Wide Format Inkjet Printer

10 Tips To Keep in Mind Before Buying A Wide Format Inkjet Printer

Avoid Major Pitfalls in Buying Commercial Printing Equipment. An Absolute Must Read for Entrepreneurs New to the Print Industry.

Wide-format inkjet printing is a lucrative business. There are many industries and individuals who need wide format prints. The applications for inkjet prints are endless and this demand translates into an excellent business opportunity.

But entering this business and making it run successfully, is not easy. There is a knowledge barrier that restricts competition in the inkjet printing sector. You require specialized knowledge to run a print shop. And this specialized knowledge will lead to enhanced profitability.

Don’t get me wrong. I do not claim that running a Print-for-Pay business is rocket science. But it does require some level of expertise and know-how. One cannot just walk in, throw large sums of money on a huge, technologically advanced piece of equipment and expect to turn a profit from day one.

I have been in the print industry for a decade and a half now and made a ton of mistakes in my business. Some of them, very very costly. There is hardly a type of printer that I have not worked with, run into the ground, broken and repaired (or failed to).

And while my knocks came at a price, they also gave me a lot of experience in this field. And this post is all about sharing that hard-earned (and sometimes tear-bringing) experience. 🙂

The owner of a digital print shop, like any other business, needs multiple skill sets. He needs to be proficient in the use of computers, be familiar with design software, have a head for marketing and accounts, and let’s not forget HR.

But the real hero of a print bureau is obviously the wide format printing machine and the applications that you can run off it. You need to have the ability to make the most out of your biggest capital investment.

So, if you are planning to get into the digital printing business, I cannot emphasize how important it is, for you to invest in the right inkjet printing machine.

There are scores of big brands out there all selling a variety of inkjets based on different technologies. Make the wrong choice from among this vast selection, and there is a good chance that your budding business will fail even before it gets a chance to take off.

I really don’t want to scare you. As I said in the first line of this post, wide-format inkjet printing is a profitable business. Play your cards right and soon your biggest worry will be about which destination to pick, for your third annual vacation 🙂

But a word of caution before you jump in. Industrial inkjet printers are expensive. They work beautifully for their intended application. But if this application does not match up with your needs and business goals, you will find yourself in the proverbial deep-end without a rope.

Even large, well-established companies have been brought to their knees by making the wrong capital investment in machines. And that is why I have crafted this post to highlight the pitfalls while making a purchase decision about the wide-format inkjets, best suited to your business.

Through this post, you’ll not just be getting insights and tips to buy a wide-format inkjet printer, but also how to start an inkjet printing business.

Three disclaimers first. If you are reading this post, it means that you are looking for advice on how to buy the right kind of printing machine for your business. So I will make the following assumptions:

1. You already know what inkjet printing technology is and have a fair understanding of how these machines work. But if you prefer to brush up on your knowledge, do jump to this post here on what is a wide-format inkjet printer, its applications, and ink types.

It’s the first in a 2-part guide on understanding wide-format inkjet printers, how they work, and how they are a vital part of a digital printer’s arsenal today.

2. Part 2 of the above-mentioned guide is about printing inks. More particularly about inkjet printing inks. I am assuming that you are aware of the different ink chemistries used by different printers. The properties of the inks determine the end-use and applications that you will be able to cater to, in your print shop.

I need to repeat this because I feel this fact is important and often overlooked by first-time buyers of production level inkjet printers.

Different inks have different strengths and limitations. Based on its strengths, a production-level printer is suited for certain commercial applications. But there is no single printer model that can cater to every wide format printing application under the sun.

Let us for example, assume that you buy an inkjet whose prints are rated for indoor use. You obviously cannot use this machine to print outdoor hoardings and banners. A huge hoarding printer on the other hand obviously cannot be used to generate thumb-sized vinyl stickers.

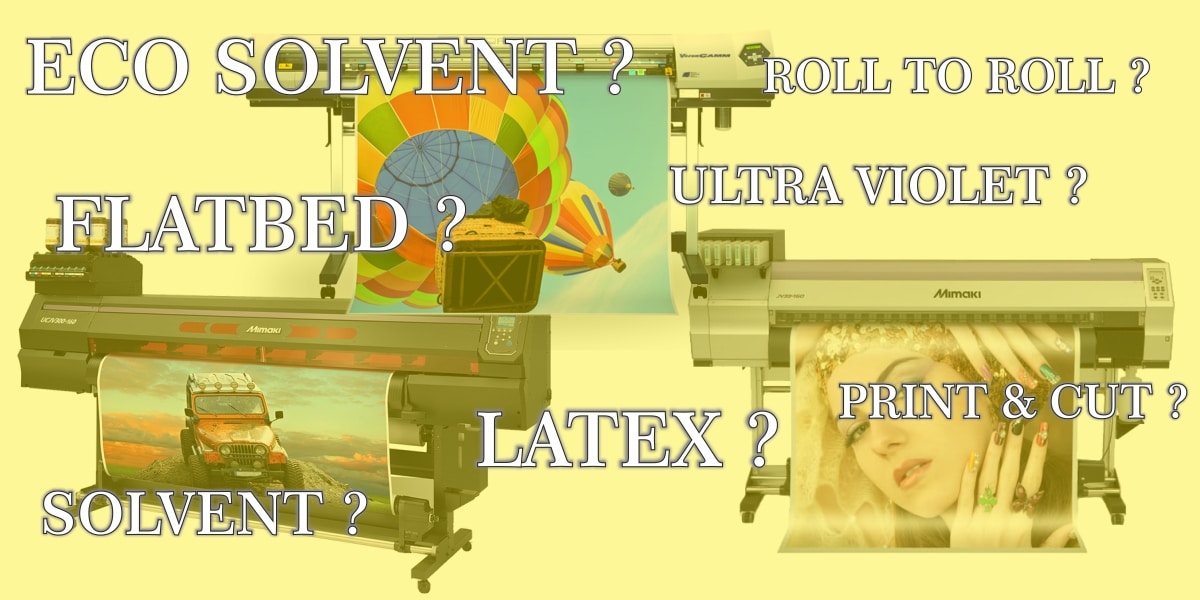

Inkjet inks are mainly available in 5 different flavors:

- Aqueous inks

- Solvent inks

- Eco-solvent inks

- Latex inks

- UV / Ultra Violet Inks.

If you need to remind yourself about the advantages, limitations, and technical differences in these inks, do read this post here.

3. Finally, this post does not review any particular printer model. It tries to do something better…

It lists important parameters against which you can evaluate every wide format printing machine in front of your eyes. I have also added some tips about the print for pay business in general.

On reading this post, you won’t just get insights into buying an inkjet printer, but also on how you can start and run your own printing business.

Now, if you happen to be in a hurry, or just want to keep the pointers engraved in your mind as short notes to refer to, here’s a quick list of the 10 tips covered in this post, sans the detailed explanations.

- Work out the True Cost of Printing a Job on the Printing Machine You Plan to Buy

- Pay Attention to Printers With Enhanced Capabilities

- Check If Third-Party Bulk Ink Feeding Solutions Are Available

- Printhead Maintenance and Replacement Cost

- Check If Engineers and Support Staff Are Readily Available

- Beware of Marketing Hype Surrounding Industrial Inkjet Printers

- Follow the ‘Rule of Ten’

- Ensure That You Have Finishing Equipment in Place

- Gather Knowledge of Design Softwares

- Understand the Market That You Will Be Entering Into. Do Market Research and Analysis.

10 Tips You Have to Consider Before Buying a Wide Format Inkjet Printer

1. Work out the True Cost of Printing a Job on the Printing Machine You Plan to Buy

A wide-format inkjet printer is a large capital investment. You will be working with this asset for years to come. And so, getting your budget right is perhaps the most important thing you can do, before committing yourself to the project.

I have seen so many print house owners make a purchase decision based on just two considerations…

- The cost of the machine.

- The cost of running the machine. By this, I am referring to consumable costs like inks and spares which need to be periodically changed

But your ROI (return on investment) calculations will be heavily skewed if you do not factor in a lot of secondary/hidden expenses associated with a print shop project. In addition to the cost of your inkjet printer and its running costs, a prospective entrant in the printing business also needs to factor in the following expenses, in his budget:

- The cost of funds. Even if the machine is financed from money out of your own pocket, you need to add in a notional figure of bank interest in your calculations.

- The cost of electrical power needed to run the printer. This can become significant in some machines. Especially the ones fitted with internal heaters. Your monthly power bill will impact your bottom line.

- The cost of backup power. If the power supply at your place of operations is erratic, installing a UPS and scores of batteries becomes mandatory. A UPS will protect the sensitive electrical components of your high-end print equipment.

- Add in the monthly rental for the workshop to your cost sheet. Even if you own the place.

- The monthly salary for the operators is another expenditure that you need to account for. This is because you do need skilled or at the very least semi-skilled employees for running the machines.

- Machine Breakdown Insurance: Perhaps the biggest expenditure in running a print shop are the contingencies that nobody can foresee. But trust me. S*** happens. Machines break down. Printheads jam and have to be thrown away. Circuit boards and PCBs fuse or even burn out. And the cost of repairing or god-forbid, replacing these parts is sky-high. I have seen print providers slave away on their machines for a year to eke out a profit. And then seemingly out of the blue, one major part of the machine blows and they are back to square one. So buy machine insurance and buy yourself some peace of mind.

- Budget for design software. Your customers will be sharing files in a variety of formats. Obviously, you will need to buy a variety of design software (like CorelDraw, Photoshop, Adobe Illustrator, etc.) to process these jobs.

- You also need to budget for air conditioners, exhausts, and environment control systems like dehumidifiers. Inkjet printers need controlled environments to work efficiently. Print heads misfire at high temperatures. Dust clogs up the carriage rails and gears. A clean and climate-controlled print room is an absolute must for the efficient running of your sensitive equipment.

Include all the above points in your project feasibility report. Then and only then will you be able to arrive at a meaningful selling price for your print products.

2. Pay Attention to Printers With Enhanced Capabilities

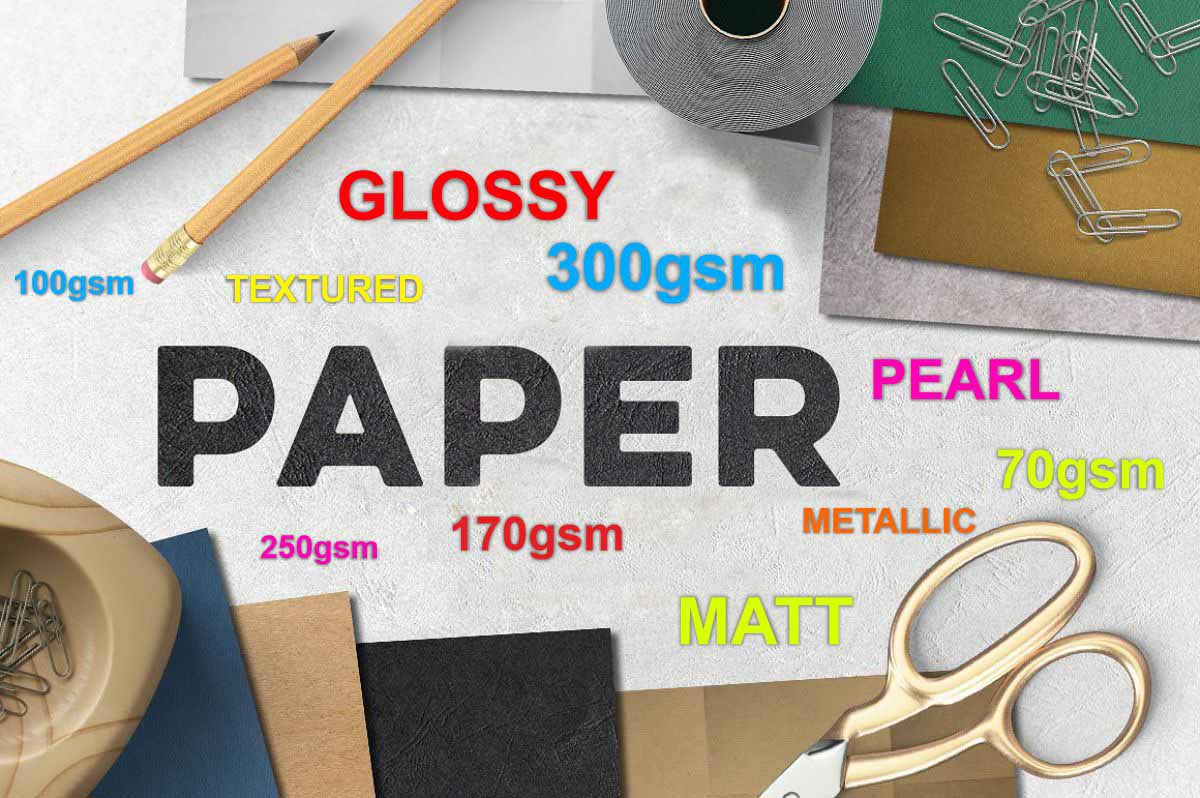

Look for a wide format printer that will enable you to deliver varied applications to your customers. In the printing business, the more media and substrates you can print on, the more end-uses you will be able to cater to.

Every printer can print on large rolls of flex and vinyl. And make no mistake. Vinyl posters and flex banners are going to be a large part of your annual turnover.

But the outdoor hoardings and indoor prints market is heavily saturated. The margins on these products are wafer-thin. Your print shop needs to differentiate itself from the competitors by adding value to our services.

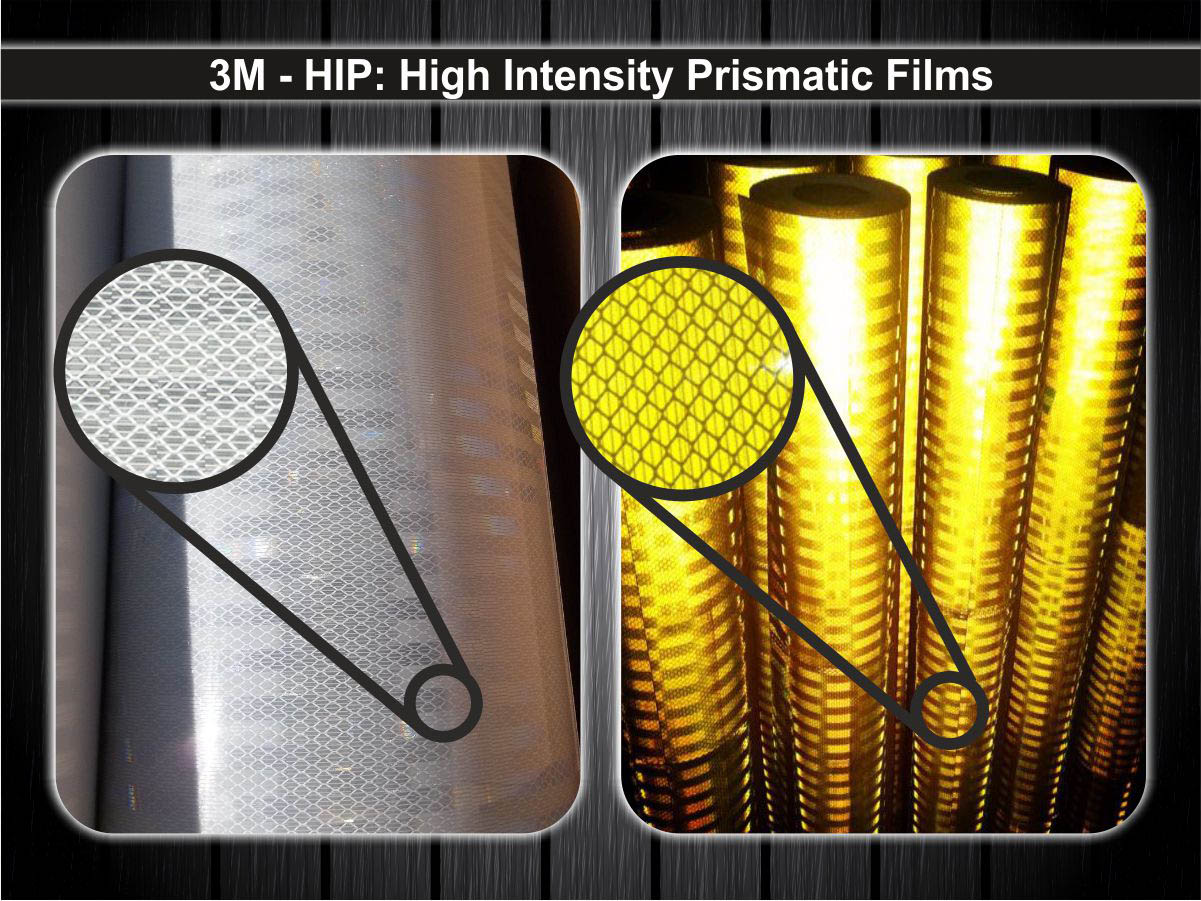

So when you are looking at prospective brands of printers, focus on models and technologies that have enhanced capabilities.

- For example, Roland, Mimaki, and HP companies all have high-resolution wide format printers in their stable. But they also have variants which offer print and cut (kiss-cut) capability to the machines.

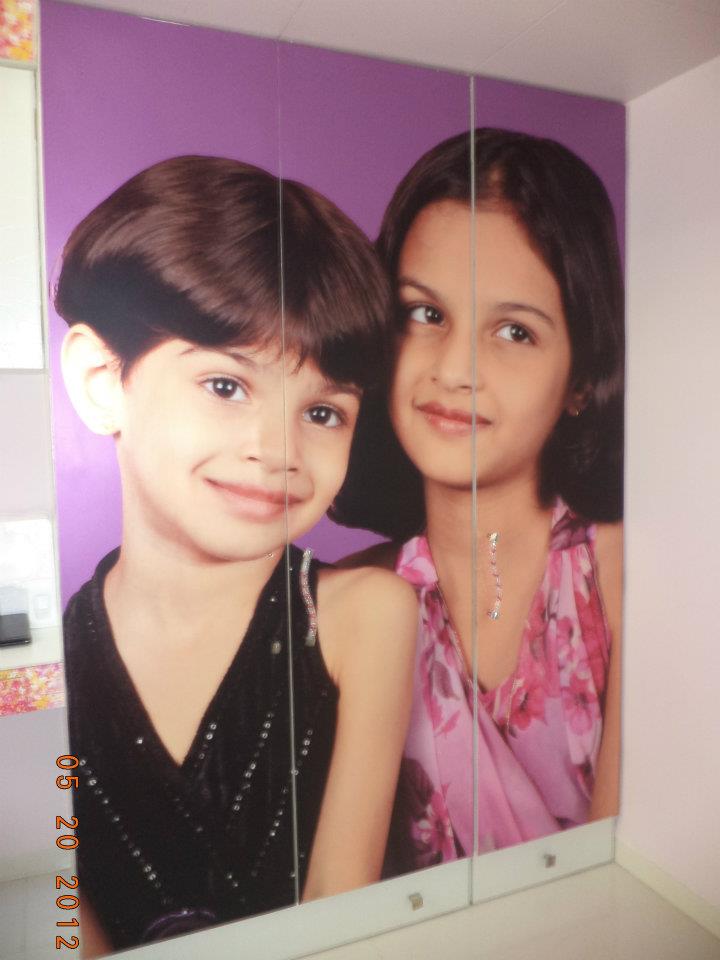

UV printers are able to print on uncoated substrates. This means that armed with this machine, you can offer prints on exotic media like leather, cloth, metal foils, custom wallpapers, curtains, wall blinds, etc.

- Some wide-format printers can be equipped with additional inks over and above the standard CMYK configuration. White inks help in producing beautiful glass films. Clear/transparent inks are used to print premium-grade stickers with a 3D embossed effect.

Additional functionality on the same equipment definitely makes you more competitive and helps you access new revenue streams. But this functionality also comes at an added cost.

UV inks are significantly costlier than aqueous and solvent inks. Print and cut machines are almost twice the price of their print only counterparts.

How much of a premium to pay, for the potential profits that come from specialized jobs, is a call every print shop owner will have to individually make.

3. Check If Third-Party Bulk Ink Feeding Solutions Are Available

The biggest cost in running a car is obviously the petrol it consumes. Likewise, the money you pay for the inks that your printer runs on, will affect your bottom-line and will also determine how competitive you are, in the market.

Every printer recommends a particular brand of inks for use with his machine. And most print manufacturers also manufacture the inks.

For example, HP claims that its printers are designed to work best with HP inks. Likewise, Roland, Canon, Mutoh, Mimaki, and every major brand of printer manufacturer also sell their own ink formulations for use with their machines.

Original inks come filled in an ink cartridge that slots into the machine. And as the ink gets over, you have to buy a new cartridge from the parent company to replace the old one.

Each cartridge is also fitted with a special chip to counter duplication. The printer initializes only after reading the chip fitted on the original cartridge supplied by the manufacturer.

But there are a whole lot of companies that manufacture only inks. Moreover, these inks are compatible for use with most of the major brands of wide-format printers. The inks are fed into the machines via specialized feeders which bypass the original manufacturers’ cartridges entirely.

Most importantly, (and here is where things get interesting) third party ink solutions are available for a fraction of the cost you pay for original ink cartridges purchased from OEM suppliers. (Original Equipment Suppliers)

So, one of the most important questions you need to ask your printer manufacturer is whether his machine will accept third party bulk ink feeders. Remember, an answer in the negative will significantly impact your profit margins.

Some print manufacturers void the warranty on their machines if they discover that third party inks have been used on the same. So, you need to seek clarity on this issue as well before you make your purchase decision.

4. Printhead Maintenance and Replacement Cost

Perhaps the single-most costliest component in your wide format printer is your print head. A machine running 4 colors (CMYK) might be equipped with 4 print heads – one for each color. Larger capacity machines have 8 heads, two for each color, and so on.

My WIT-Color Challenger solvent inkjet printer has got 8 Konica Minolta printheads installed in it. With multiple heads, this beast of a machine can easily process 1000+ square feet in an hour.

But on the flip side, each of these printheads cost a lakh of rupees. And this is the potential loss I face when even a single head goes bad and needs to be replaced.

Now, printheads have hundreds of microscopic nozzles in them. The inks jet out of these nozzles. But very often, these nozzles start jamming or misfiring. And when this happens, the machine’s print quality seriously deteriorates.

Different machines require different levels of maintenance. In most aqueous printers, with the inks made of water, all you need to do is wipe the nozzles with a wet cloth.

Solvent ink printers on the other hand need to be continuously dipped in solvent to keep from drying up. UV machines are kept constantly powered on. The inks are forever cycling through the ink systems because there is a danger of them drying up.

So when you are buying an industrial printer first verify the cost of each printhead. I pray to God that you never have to replace them. But should that misfortune ever befall you, you need to be aware of their replacement cost.

Also, check how good, the engineering or build quality of the machine’s ink systems are. There are scores of printers which are cheap knock offs of the more well-known brands. But maintaining and running them is a nightmare.

5. Check If Engineers and Support Staff Are Readily Available

The best equipment in the world becomes a useless piece of metal when it breaks down and there is nobody around to fix it.

Wide-format inkjets printers are complex machines. Printers sold by even the well-known brands will break down occasionally. And you will need company engineers to come over to your place and fix the issue.

Your job in this scenario is to then minimize machine downtime and the consequent loss in productivity.

So check with your print supplier if qualified engineers are readily available to help you, in your time of need.

I know of a printer manufacturer who has got just 6 engineers to service machines throughout Maharashtra (excluding Mumbai). So what do you think happens when a machine breaks down in far off Jalna? I am guessing that the poor vendor must be tearing out his hair in frustration while waiting for the service guy to turn up.

Most of the big printer brands like HP, Canon, Roland, etc. have their own offices and authorized service centers at numerous locations. But if your printer manufacturer does not have a proper support team in place, do not buy the machine from him, no matter how good a deal he offers you on the same.

6. Beware of Marketing Hype Surrounding Industrial Inkjet Printers

Salesmen are generally very enthusiastic about their products. They tend to oversell their brand. And I do not blame them. These guys are, after all, just doing their job. But some marketers are downright shady. And these crooks very often misrepresent the products they are selling. I have come across marketing guys who have:

- Overstated the capabilities of the machine

- And failed to disclose the shortcomings of the printer

- The worst ones downplay or even hide the real costs associated with the printer

When you are out buying a new machine, it is your job to talk to as many salesmen as possible. I even recommend that you request machine demos from the marketing representatives of the company. These interactions will help you weigh the pros of one printing machine against the other.

But at all these sales meetings, I want you to be a bit of a cynic. I want you to take the company’s claims with a pinch of salt.

For example, if the salesman says that his machine outputs 100 square feet in an hour, jot down a speed of 80, in your notes. If the cost of inks is shown as Rs.10/- per square foot, assume Rs.15/- in your profitability calculations.

Again, I am not saying that their claims are lies. The salesmen will have some logic in place to back their statements. But that logic tends to very often break down, in the real world. All I want is for you to be conservative in your projections.

Keep a buffer before buying a machine and you will be cushioned against rude surprises later on.

There is one other, very common tactic that I have seen many printer salesmen use. They start by giving me a reference of a big print house (whose name is well known to everybody in the print industry). They then proceed to give examples of how the said print-house made lakhs of rupees by using only their brand of machine.

The salesman then becomes extremely persuasive in this vein. Listening to them makes me think that all I have to do is invest in the goose they are selling. What remains, is for me to then sit back and wait for the bird to lay a golden egg every day.

But I find this ‘successful run in a big print house’, argument specious. The owner of a big print house already has a ton of experience, loads of manpower, a lot of goodwill, and a whole lot of customers at his doorsteps.

So he is bound to turn a profit irrespective of whether he uses this marketing guy’s machine or any other similar piece of equipment.

Limited Period Offers

Salesman offering ‘huge discounts’ only for a ‘limited period of time’ is perhaps the oldest trick in the book.

Wide-format printers, unlike oil and natural gas, are not finite resources. New and better printers are being launched every day.

So, if there is a huge discount on a particular model, it is there to stay and probably will not be rolled back. A discount is a good thing but low pricing should not be the sole influencer of your ‘buy’ decision.

You should in fact ask yourself questions such as:

- “Why is this model being deeply discounted?“

- “Is it being phased out?”

- “Is there a better version being launched?”

- Or God forbid, “Does this machine have some major drawback?”

7. Follow the ‘Rule of Ten’

I have formulated something known as ‘Orchid’s Rule of Ten.’

This rule states that only after a printer model is successfully installed at ten other print shops, will Orchid Digitals even consider buying it.

Wide-format printers are continuously evolving. New features and capabilities are added in every version. And new printer models are generally launched with a lot of fanfare. But take care not to get carried away by this.

Just like software, new iterations of digital printers come with their own set of bugs and design errors. So wait for a model to settle down and prove itself in the market. Source reviews from other users and only then put down your money on the machine.

8. Ensure That You Have Finishing Equipment in Place

No man is an island. Similarly, no wide-format inkjet printer is a standalone solution. Sure, the machine will generate the prints that your business depends on. But these ‘raw’ prints will need some finishing before it becomes a final product that can be sold across the counter.

For example, an oven will bake your pizza for you. But you will still need a packing and delivery section to push that double cheese pepperoni into a box and bring it to your client’s house.

Similarly, depending on the end application, there are a whole lot of print finishing machines available. And while you need not buy each and every one of them, investing in the ones suitable to your setup, will make you that much more efficient and competitive.

Here is a list of some ancillary equipment that you will need, to convert your raw prints into finished products:

Seaming Machine: Large hoardings are not printed out of a single piece. Rather, they are composed of multiple tiles all joined together.

For example, let us assume that you have a 10 foot wide, wide format printer. This means that the maximum width of print that your machine can generate is 10 feet. So, let us see what happens when your customer walks in with a 30 feet hoarding job:

- First, you need to break the artwork into 3 parts of 10 feet each.

- You then print each of these three, 10 feet tiles, on your printer separately.

- Finally, you need to seam/join these discrete tiles to create one continuous hoarding print.

There are specialized heat seaming machines available that glue large prints together. And to process large hoarding jobs, you will have to budget for one such machine in your print shop.

Large Lamination Machine: Vinyl prints need to be laminated with a protective layer of film on top. In simple words, laminating means pasting a plastic sheet on top of an existing print.

This film protects our print from water, fading in the sunlight, dust, scratches, daily wear, and tear, etc. Vinyl prints also need to be mounted on thick sheets of sunboard. Sunboard or foam sheet, essentially adds rigidity and thickness to our flexible prints.

In either case, whether you need to mount a print on a sunboard or laminate it with a protective film, the job is too large to be done by hand.

You then need a specialized hydraulic press to do this for you. Laminating machines are typically 5 feet in width and can easily handle prints hundreds of feet in width.

Large Cutting Table: Let us assume that you have a number of print jobs of varying sizes. Some artworks may be of size 2 feet, others 3 feet, 4 feet, and so on. To save media costs, you then club these various jobs on one large 5-foot roll of vinyl.

The printer then spits out a single print of 5 feet width having multiple artworks nested within. Obviously, you cannot hand over this large, unfinished roll to your customers. What you then need to do is cut the large print into its individual components.

But, if you use hand scissors to do this, the finished job will end up having crooked, shabby-looking edges. To overcome this problem you need a large cutting table in your premises where the prints can properly be trimmed with cutting blades.

Grommeting Machine: This is a nifty piece of equipment that fixes eyelets or grommets on your banners. End users can then loop ropes through the holes in the eyelets to string the banners in place.

CNC Router: Some specialized jobs need rigid boards to be cut in various shapes. Product display stands and shape cut standees especially are difficult to finish by hand. A CNC cutting router greatly helps, in this case.

Stretching Table: If you provide canvas prints, your customers might ask for them to be stretched on a frame as well. A stretching table, equipped with clamps, etc. might then be needed to deliver a professional job.

End-Point Pasting and Installation Team: End-users or buyers of your prints will very often ask for the prints to be installed on-site.

Transparent or frosted films need to be pasted on glass partitions in an office. Custom printed wall-vinyls need to be installed on walls, sunboard and photo frames need drilling, etc.

Some print providers choose not to get involved in end-point installation services. Others (like Orchid Digitals) provide a full solution, ranging from the print to its final installation. If you opt for the latter, your organization will obviously need a pasting and installation team on standby.

9. Gather Knowledge of Design Softwares

A print shop owner needs to work with a variety of file formats. Customers provide artwork in Adobe Illustrator, CorelDraw, Photoshop, and even MS Office.

You do not need to be an artist or proficient in designing, to run a print-for-pay business. But you must have a working knowledge of these designing softwares. There are some things that you need to be familiar with, at the very least:

- You have to be aware of which file formats work with which design software.

- You have to be able to use the basic tools in each software to make minor corrections, alterations, and layout changes in your clients’ files if needed.

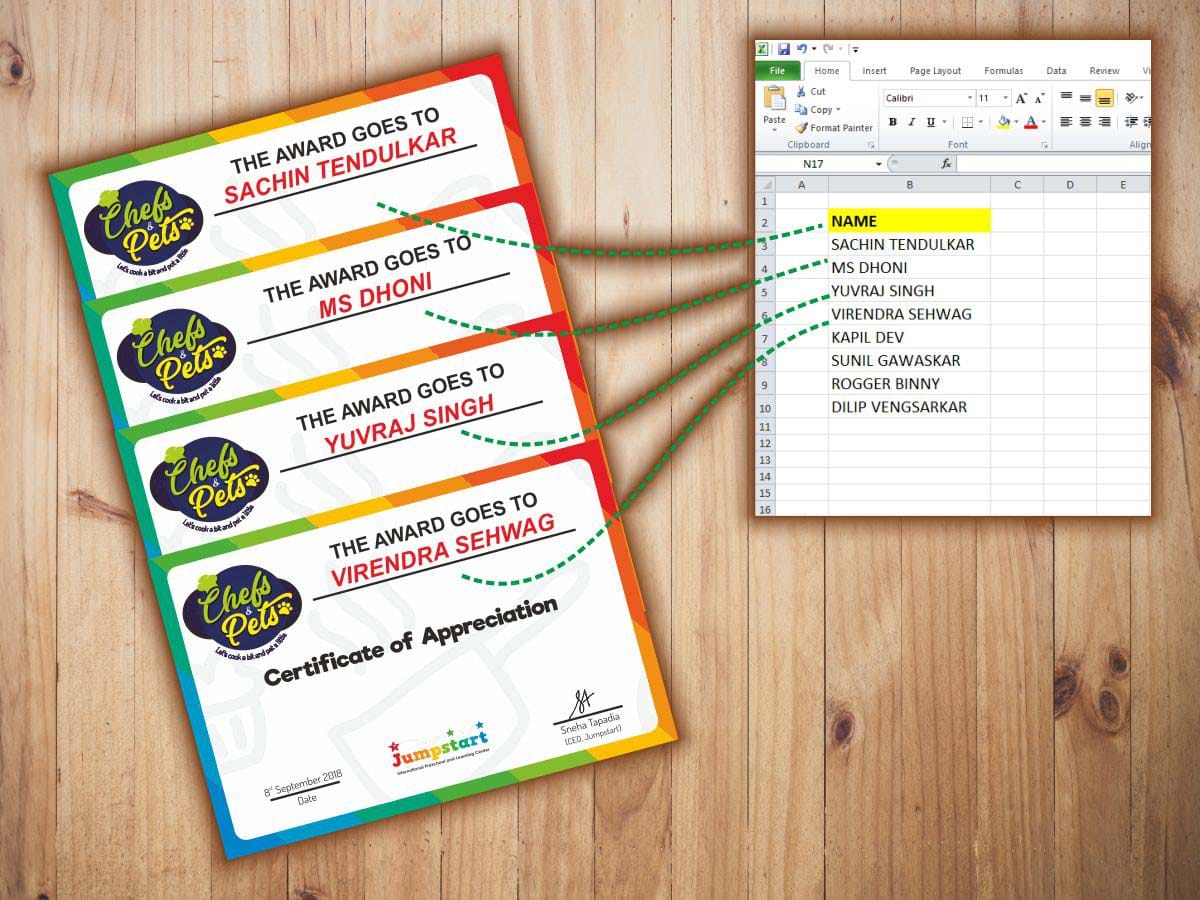

- Variable data printing is a value-added service provided by digital print shops. Most design softwares have VDP modules built within them. Familiarity with these modules will greatly help you. In case you are curious, read more about VDP here.

10. Understand the Market That You Will Be Entering Into. Do Market Research and Analysis.

Every business needs to be studied before you invest in it. And so, long before you make a down payment on your wide format printer, you need to study the market that you will be entering.

Here are some areas that you need to research and tips that will help you in your analysis.

- Check which brands of printing machines are the most popular. If over half the print providers in the city have HP machines installed in their premises and only a minuscule have opted for, let’s say the Roland brand of printers, there must be a good reason for the same. Try to figure this reason out.

- Find out which ink technology your competitors are using. If existing printers are running jobs off aqueous and solvent machines it means that they are already catering to the larger demand for indoor and outdoor prints. So it is going to be difficult for a newbie to make a mark here.

But is the competition providing print and cut stickers as well? Who is providing the speciality services that can only be processed on a UV printer? Answers to such questions will help you make a more informed decision.

Some examples of special jobs that only a UV printer could generate are white ink prints for glass films, clear ink prints for spot lamination or prints on unconventional media, like a roll of leather for furniture applications. The demand for specialty jobs is obviously going to be lower than that of mainstream jobs. But the profitability of the same will always be much higher.

So if your studies show that there aren’t many UV or print and cut machines in your city, this then becomes a niche that you might want to exploit.

- Go to trade shows. Exhibitions are great sources of information. Exhibitors are willing and in fact, waiting to impart invaluable knowledge about their machines. You also get an idea of the latest trends in the industry.

I remember attending scores of print exhibitions all over the country before I started my print shop business. The two things I recommend you do at trade shows are:

- Keep asking questions, even if you think they are dumb. The answers will clarify a lot of doubts and will help you gain insights into the print industry.

- Do not hesitate to go and stand at the stall showing the costliest most technologically advanced printers. You may or may not have the funds to buy this equipment. But that does not matter. You will gain a better understanding of what advantages these high-end printers provide. You can then hunt for the same in lower-end models that fit your budget. It’s like saying that I only have the money to buy a humble Toyota. But that does not stop me from checking out the cool features of a Ferrari.

A Purchase Decision of a Lifetime

I hope that these 10 tips for buying a commercial printer help you in your quest. They are based on my own experience in the print industry and the challenges I faced while making purchase decisions.

And if these tips steer you away from the pitfalls in the industry, if they help to turn a profit, I will consider my efforts well rewarded. Be confident, familiarise yourself with this guide to buying a wide-format inkjet printer, and get to business!

Do let me know what you think. Add in your own insights and let me know which machine you finally purchased. Cheers and all the best for your new endeavor.

Share

Looking for any specific product?

Drop us a line. Send us your query. And we’ll get back to you with solutions and answers.

Mitesh Sanghani

Mitesh lives, mostly for Saturdays.

But when forced to work, you’ll find him heading Orchid Digitals – a printing press in Pune.

If it’s an emergency, try looking for him in the hills behind his house. You’ll almost certainly find him… lazing under a tree, with a book in hand.

Similar Blogs

Related Products

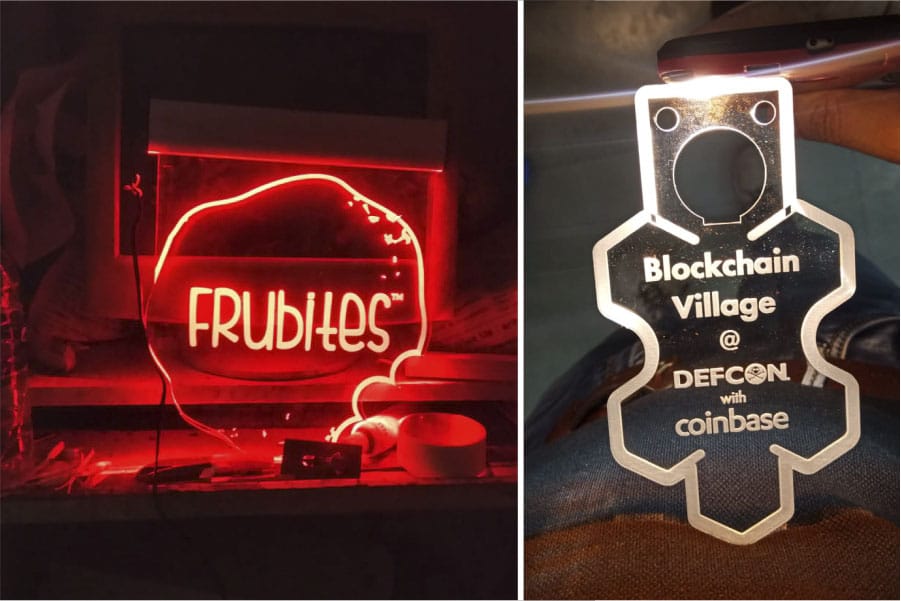

Edge Lit Acrylic Frames

We engrave logos, words and designs on a sheet of acrylic using a laser marking machine. We then fit a strip of LEDs on edge of the acrylic sheet. The light passes through the acrylic to make the engraved areas brightly glow. This results in a very unique sign solution that is guaranteed to wow your clients & customers.

All our Blogs

This is a section packed with useful knowledge on digital printing and its aspects, interesting printing case studies, and ideas, guides, and tips & tricks on marketing and branding.

Beautifully written essay. Well researched.

I was so confused about which printer will be perfect for my business but thanks to this great share, after reading this blog now I took the decision to buy the https://printersmag.co.uk/best-inkjet-printers/ This blog truly helped me. Keep sharing more like this.

Thankyou for this amazing blog about tips to buying wide format printer. For more details visit https://www.printerydubai.com/

Hats off for this content. Thank you for providing buying guide about a wide format printer.