How to Start Your Own Digital Printing and Signage Business – & Turn A Profit On The Same

Hey there! I’m Mitesh Sanghani, and I am here to take you on an epic journey that’s been more of a rollercoaster than anything Disney or Imagica could ever dream up.

I run Orchid Digitals here in Pune, Maharashtra. We do wide-format printing, sheet-fed printing, laser cutting and engraving, and even CNC routing. It’s a mouthful, I know. In simpler terms, we can whip up everything from tiny A3-sized posters to banners big enough to make King Kong blush. Logo boards, glow signs and neon sign solutions? We’ve got those down too.

Now, before you start thinking, “Great, another sales pitch,” let me stop you right there. This isn’t an ad to woo you over to Orchid Digitals (although you’re always welcome to swing by and say hi 👋). No, my friend, I’m just setting the stage to show you that when it comes to the digital printing and signage industry, I know a thing or two.

But let me confess: Orchid Digitals wasn’t an overnight success. It took a good two and a half decades to reach here.

I sometimes wonder if I could have achieved my current career stage much earlier in life had I been aware of the correct and complete information about the digital printing industry. And had I not made some huge errors of choice and judgment along the way?

Let’s rewind to the turn of the century. A young Mitesh, armed with dreams and a pinch of naivety, diving headfirst into the treacherous waters of digital printing. Spoiler alert: there were sharks.

Twenty-plus years later, here I am, still standing. And between you and me, if I had a chance to send a few choice words to my younger self, I would have said… ”Dude, read this blog post. It will save you a world of hurt.” And oh yeah. “Buy Bitcoin,” would have been another thing I would have mentioned to the 26-year-old Mitesh. 😉

I’m sharing my wild, two-and-a-half-decade ride with you so you can skip the pitfalls and potholes I face-planted into. And so that you can also nail the business strategies, machinery choices, and marketing know-how right from the start. This blog post is like the cheat code to the game of digital printing, except it’s not cheating if I’m just helping you out. 😉

Here’s what we’re diving into:

- How profitable is this venture? Is the digital printing business a gold mine or fool’s gold?

- What’s the real estate requirement for your shiny new print shop?

- The money talk: How much capital do you need for machinery and assorted equipment?

- Business strategy 101: What products and services should you offer your clients? (Hint: not just another batch of 10-rupee flyers)

- Which machines do I buy? Deciphering the cryptic world of printing machine brands and equipment suppliers.

- What software skills do I need? – CorelDRAW, Adobe Illustrator, Photoshop and even Canva (yep, its not as easy as you think 🙂

- What prior business experience do I need to bring to the table (because winging it only works for so long). Accounting, HR, marketing, etc., skills are an absolute must

- Conclusion: It’s all about finding happiness and the satisfaction of a job well done!

Let’s kick things off by answering that burning question that landed you here in the first place, shall we?

Is Digital Printing a Profitable Business?

Oh, you bet your bottom rupee it is! If digital printing were a reality TV show, it’d be the one everyone wants to binge-watch. Why? Because it’s got drama (hello, delivery deadlines), creativity (those jaw-dropping wall graphics), and plenty of profit potential to keep you hooked.

Let me guess: you’re sitting there, sipping chai, wondering, “But wait, isn’t the demand for printing dying with all this fancy-schmancy online stuff—emails, websites, and viral TikToks?” Well, let me stop you right there.

Sure, the internet has revolutionised the way we communicate and market our products and services. I mean, we’re all guilty of three-hour Instagram scrolls (#NoJudgment 🙂. But—and this is a big BUT—there is still plenty of room for good ol’ physical printed collaterals.

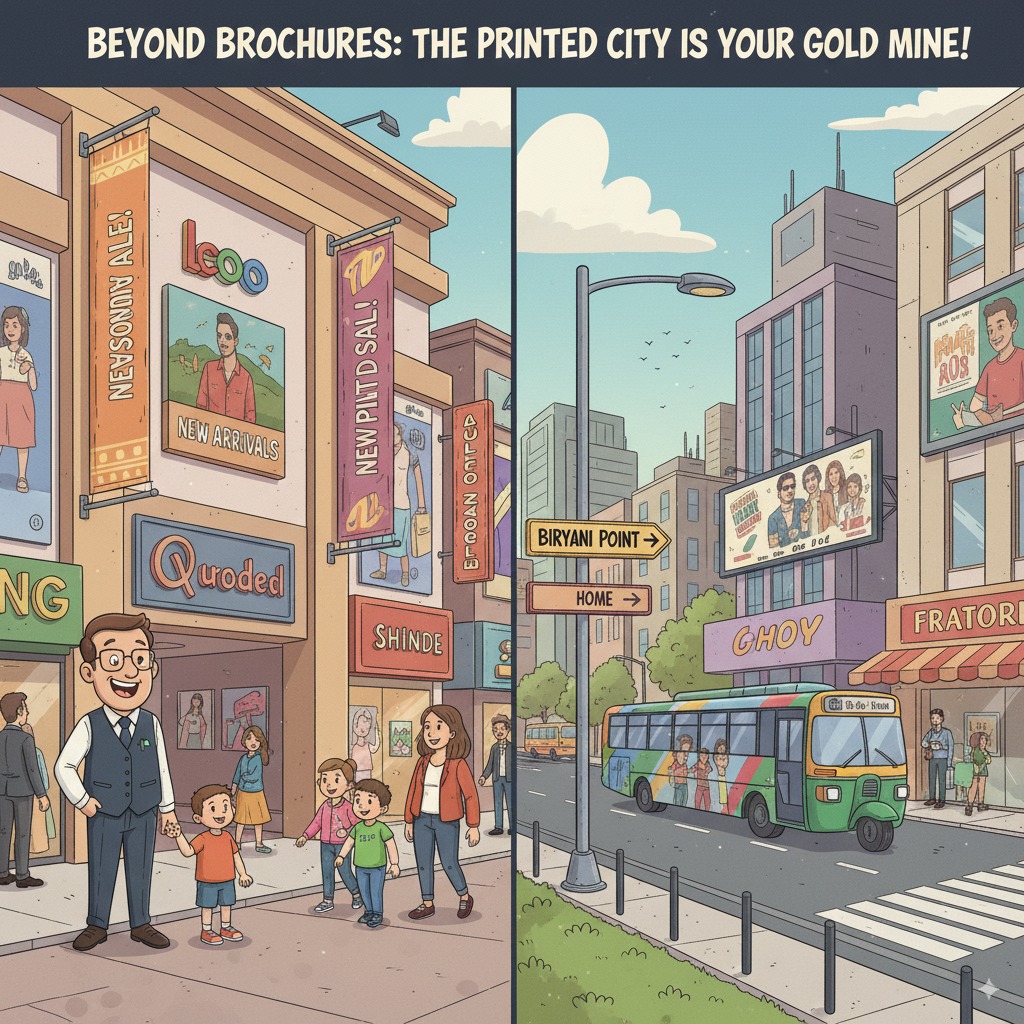

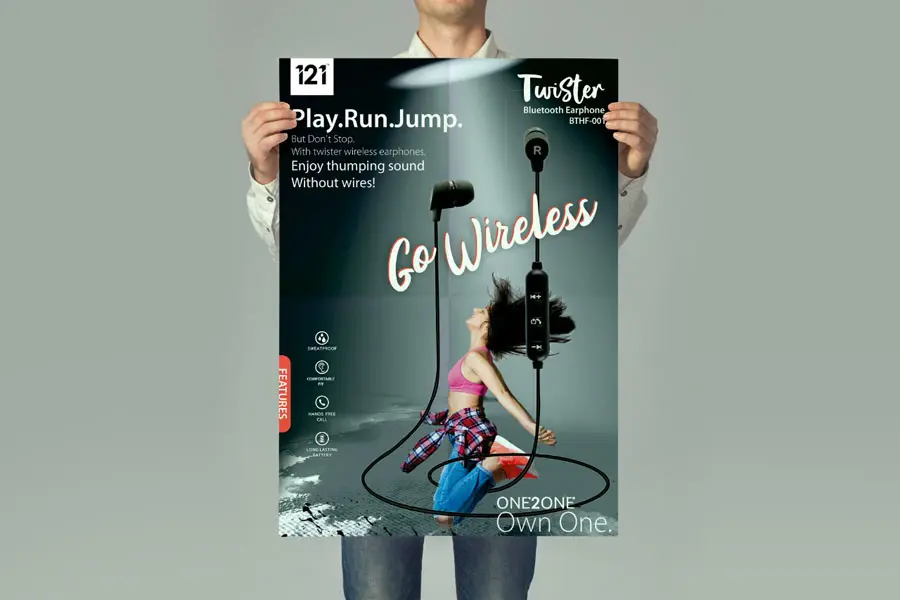

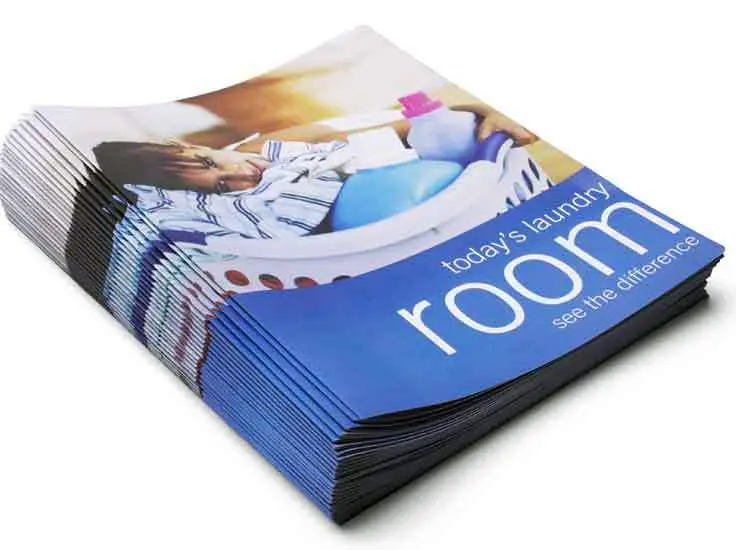

Here’s the deal: running Google Ads might reel in the leads and inquiries, but when it comes to sealing deals in business meetings, printed brochures are still your MVP. You know those glossy, gorgeous creations with specs, features, and benefits that scream, “I mean business.” In fact, brochures and fliers are a top-selling product here at Orchid Digitals.

But it’s not just brochures, folks. There is an entire range of printing products and services that you can sell to your clients. Picture a shopping mall. Sure, they’ve got flashy promo videos blasting on every social media platform, but once customers step inside the mall, they have to be welcomed by stunning vinyl banners shouting about the latest sales, logo signs elegantly perched above each store entrance, and high-resolution photo prints installed in the interiors.

Now, take a walk (or catch a rickshaw if you’re feeling lazy) around your city. What do you see? Hoardings taller than your average giraffe. Buses and rickshaws covered in vinyl advertisements. Night reflective road direction signs guiding you home (or to your favourite biryani joint ;-). There are prints and signboards installed wherever you look—and boom—that’s more opportunities for printing businesses like yours to cash in.

Yep, printing is everywhere. And it is going to remain so for the foreseeable future.

And if you really want to rake in the cash, office branding is where things get exciting.

From snazzy logo boards for reception areas to custom-printed wall vinyls and glass films, every corporate office needs printing and interiors solutions that scream sophistication. And guess who can fulfil these needs? Yep, you, with your shiny new printing & signages, business dream.

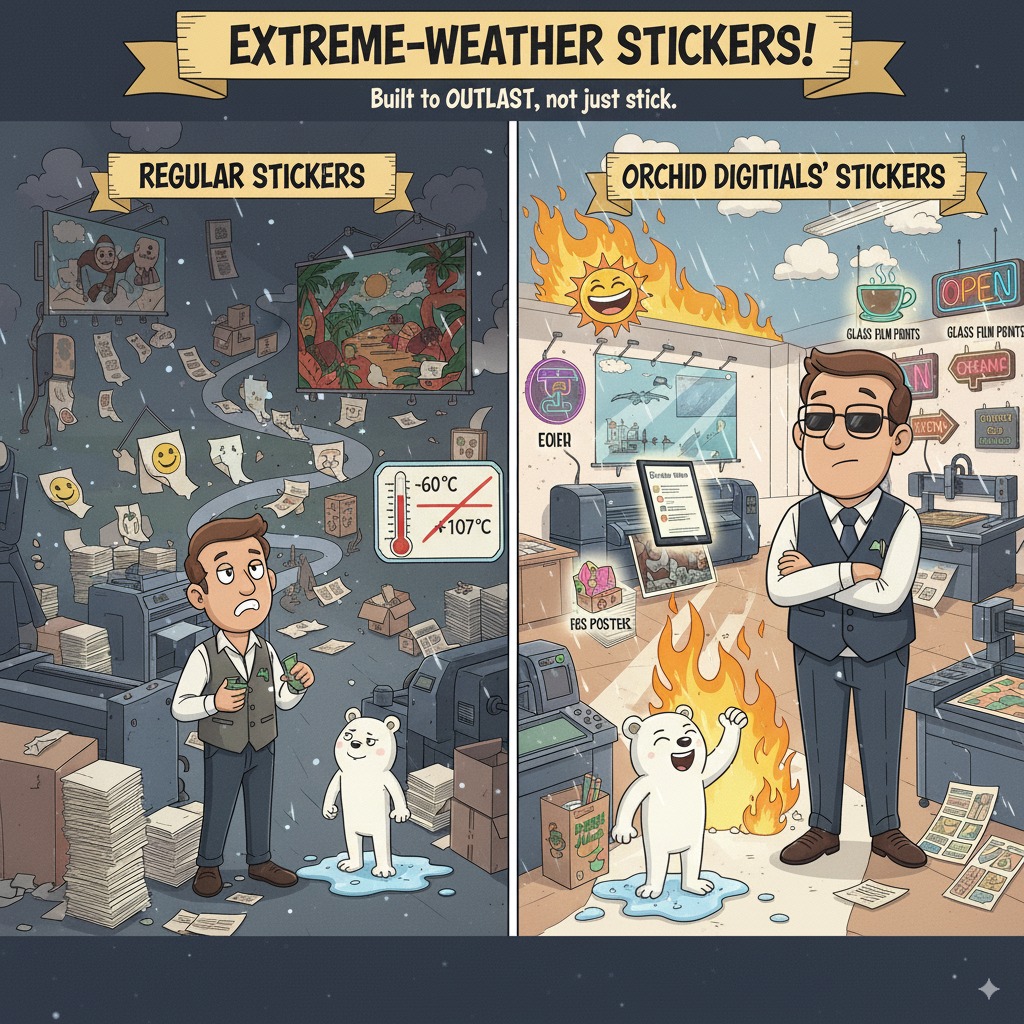

For example, let’s talk about something as ordinary and everyday as stickers and labels. Stickers might sound like something your 5-year-old niece hoards for her notebooks, but holy embossing, Batman, the sticker printing industry is a hidden goldmine.

Don’t believe me? At Orchid Digitals, we’re not just printing regular stickers that lose their charm after one rainstorm. Oh no, we’re making extreme-weather stickers—think stickers that laugh in the face of -60°C or saunter calmly in +107°C. #StickerSwag

And that’s not all. We’ve got embossed stickers that pop (literally), metallic foil stickers with rainbow hues that ooze sophistication, reflective ones that shine like your future, and glow-in-the-dark stickers perfect for night owls. Simply put, sticker manufacturing isn’t just crafting adhesive pieces of joy—it’s creating profitable solutions for every use case out there.

The Bottom Line of My Argument And The Bottom Line of Your Profits

Don’t just take my word for it. A quick Google search will unleash tons of studies confirming that the digital printing industry is growing faster than the weeds in your garden. So, whether you’re printing bespoke business signs for cafes, vehicle wraps for advertising agencies, or crazy-cool laptop decals, this business isn’t fizzling out—it’s thriving like Ross and Rachel… (before they went on a break).

The Clients Are More Demanding—And Luckily, Digital Printing is Up for the Challenge 🚀

Let’s wind the clock a few years back and talk about the traditional printing methods — screen & offset presses. These printing methods required days to deliver the finished product and could only produce mass quantities.

Screen and offset printers were absolute divas.

They took forever to show up to the party (2-3 days to print out simple exhibition flyers), had ridiculous standards (minimum order quantities), and required you to commit to way more than you wanted (seriously, who needs 5000 flyers when all you wanted was 100?).

Thanks to the marvels of modern digital printing machines, those headaches are now a thing of the past. And no, this isn’t just some marketing fluff—it’s the truth. With digital printing, you can order exactly one copy of that flyer, and it’ll still look like Michelangelo himself rolled up his sleeves and painted it.

Crisp resolution, vibrant colours, and none of that “waiting around for days” nonsense. Basically, digital printing is the hero Gotham deserves… or at the very least, the one you NEED for your growing business.

How Profitable Is the Digital Printing Biz? Spoiler Alert: Very 💰

Alright, here’s the juicy bit. You’re probably wondering, “What’s in it for me?” Well, my friend, let me throw out some numbers that’ll make your accountant do a happy dance in their cubicle: 30% – 40% profit margins. Yes, you read that correctly. This profit percentage is the bare minimum. And on the higher side, the sky is the limit!

To put that into perspective, your local wholesaler would sacrifice their favourite chai recipe to earn 5%–7% margins on his commodities trade.

But with digital printing, you’re in a whole different league. Why? Because this business isn’t just about printing—you’re solving problems, delivering dazzling signage, and sometimes adding those extra touches no one else thought of. And when you solve a problem, when you innovate or stand out, suddenly your profit margins start shooting up faster than bitcoin prices.

Case in point: If you’re printing vinyl banners, your margins are decent. But design a graphic and then go paste it on a car as part of a vehicle wrap project, and that extra effort gives your profit margins a serious leg up.

Running a digital printing business is not rocket science, but it still requires a substantial amount of knowledge and skills. But whenever you use that skill set to bring value to your clients, you start commanding a higher margin on your transactions.

Of course, this isn’t all peaches and rainbows. Running a digital printing biz requires upfront investments in machinery, space, and skilled labour. But don’t let that intimidate you—investing in your business is all part of the game.

Expanding your services (think corporate space branding, glass film prints, road direction signs or custom signboards) only boosts your returns.

Size Matters: How Much Space Do You REALLY Need for Your Print Shop? 🏘️

Here’s a little story to start us off: In Pune’s Shaniwar Peth—a buzzing hub for printing shops—you’ll see everything from print shops running out of shoebox-sized setups to massive operations that look like ISRO’s ground control.

When I got started, my shop was a humble 220 square feet. Small and scrappy but bursting with ambition. Fast forward just a few years, and I was drowning in machinery—turns out, digital printers take up more space than your that unused treadmill in your room corner.

As a rule of thumb, aim for a shop of 400–500 square feet to ensure smooth sailing. Why? Because your setup might include:

- A sheet-fed colour printer for regular-sized paper jobs 📄

- A wide-format roll-to-roll printer for those billboard-worthy gigantic prints 🖼️

- Finishing equipment like laminators and cutting machines ✂️

- A UPS (because electricity loves playing hide-and-seek during essential moments in India)

- A retail counter, where you can receive and process jobs

And let’s not forget storage space. You’ll need room for reams of paper, rolls of flex, vinyl media, consumables like inks and toners, and machine spare parts. It’s like setting up a science lab—but instead of experiments, you’re creating stunning prints.

Pro Tip: Set up shop on the ground floor. Why? Because you will be converting a substantial amount of material, and the movements of goods will be hampered if your setup is on the higher floors of a building.

Oh, and location is EVERYTHING. Digital printing businesses don’t operate in isolation. You’re going to need to outsource ancillary services for cutting, creasing, stapling, lamination, etc. And unless you own an industrial-sized printer factory with all these services under one roof, it’s better to set up your shop in an area where these support services are readily available.

How Much Capital Investment Is Required To Start A Digital Print Shop?

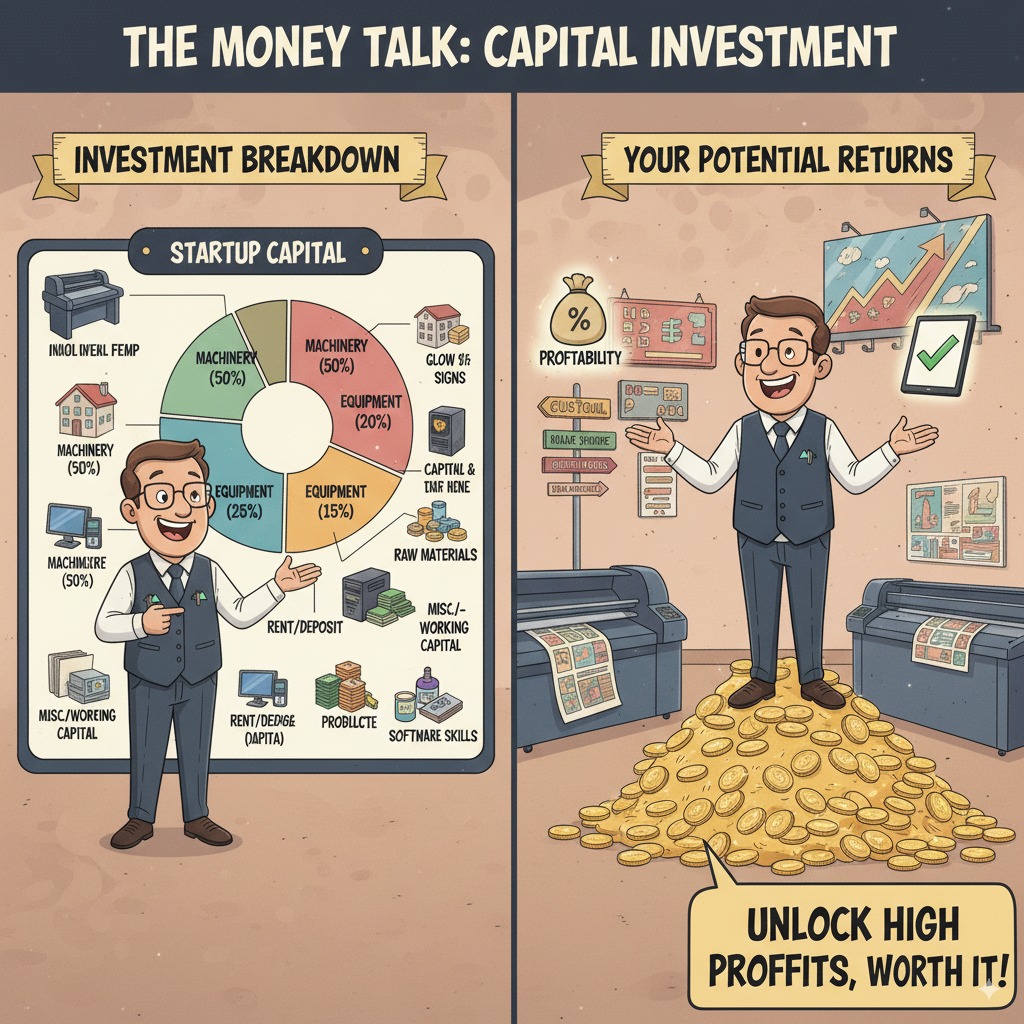

Alright, grab your coffee and let’s chat about getting your digital print shop off the ground without completely draining your wallet. Spoiler alert: We’re talking a starting price (INR 50 lakhs plus) that may cause you to faint straight away into that aforementioned coffee cup. 😅

You can kickstart a small print shop for as low as 10 – 15 lakh rupees. Sure, you can. But I have written this blog post on the assumption that you are planning to start off at a larger, industrial scale level. So, before I start listing machine specifications and their prices, allow me to share a few friendly assumptions – because hey, assumptions make the world go round!

Assumption #1: The Shop Space Saga

First off, let’s talk shop – literally. I’m gonna assume that you’ve already cracked the puzzle of acquiring a shop. Maybe you own a cosy little nook in the commercial hub of your city. Good for you, Richie Rich.

Or perhaps you’re slick enough to have figured out the rent/leasing game. Either way, we’re not going to be talking about the cash needed for the physical space in this blog.

We’ve got bigger fish to fry (like printing machines that cost more than your average second-hand aeroplane).

Assumption #2: Mid-Sized Madness

Next up, I’m assuming your dreams are somewhere in the middle ground – you’re going for a mid-sized business. Digital printing is like a buffet, where ID card prints, black and white document prints, UV DTF stickers, mugs, t-shirts are like the starters and large-sized poster prints, banners, digital colour prints, acrylic logo signs, etc., make up the main course.

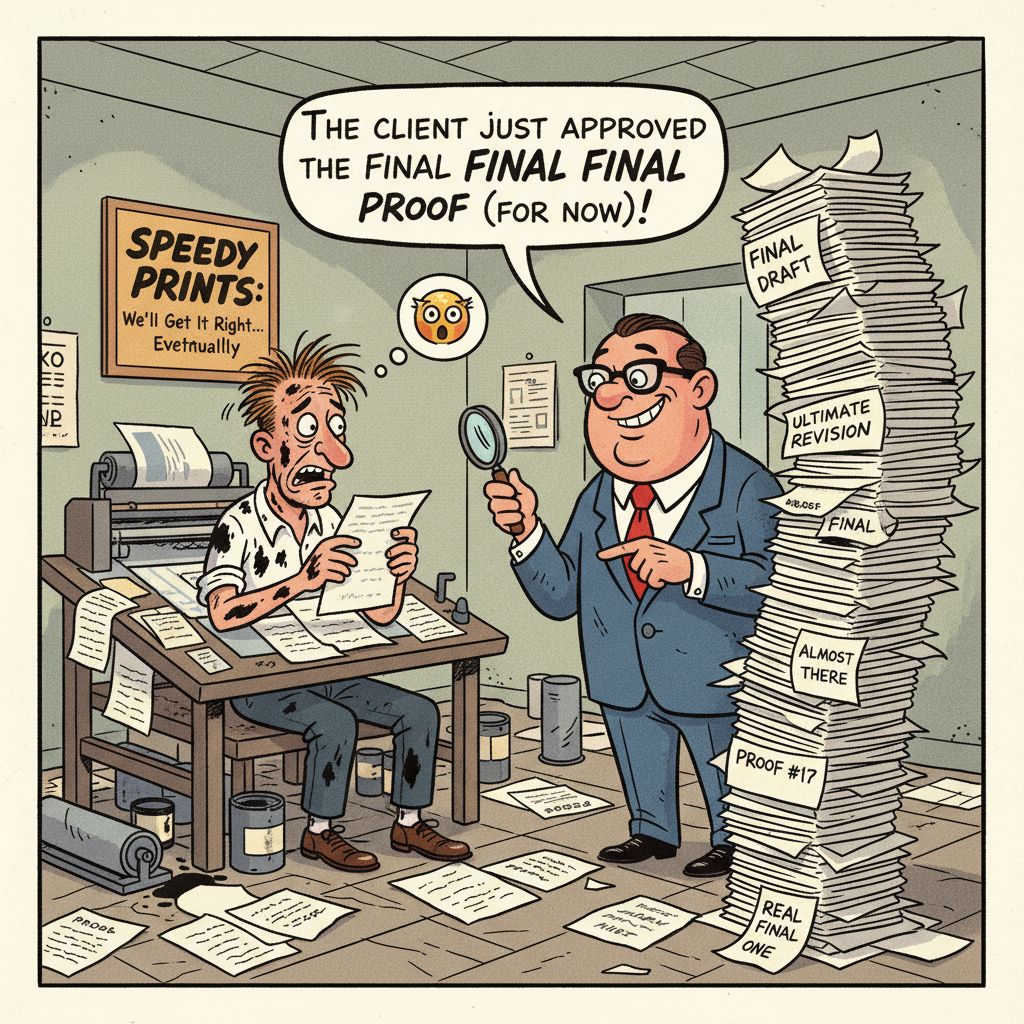

You can start off with a t-shirt transfer machine and a mug printing machine for less than ₹ 50,000. And don’t get me wrong – low-cost machines don’t mean shabby business. You can scale these operations faster than you can say “The client just approved the final final FINAL proof.“

But if you’re aiming for the big league, you’re going to need industrial-level printers.

I am guessing that you are reading this blog post to learn more about these large-sized machines. I assume that you are already aware that these machines run into lakhs of rupees and can generate large-scale production volumes.

In fact, a production-level printing machine can put you in an apex position among all the printing vendors in your city. With the ability to output large volumes, at a high speed, and very high quality, your competitive edge in the local markets will be significantly enhanced.

Assumption #3: Location, Location, Location!

Let’s hitch a ride to our next assumption. Unless you plan to rock the print world from a quaint village (where jobs generated on entry-level office printers can still make a tidy profit), I’m guessing you’re located in a tier 1 metro like Pune or Mumbai.

Here, the market’s so huge and thirsty for prints, you’ll need a production-level printer just to keep up. Trust me, it’s like being the coffee shop in Winterfell… you’re gonna need more than just one espresso machine.

With all these assumptions nicely tucked into our assumptions box, it’s time to dive into the real deal…

The Meat of the Matter: Capital Investment Breakdown of Printing Machinery and Equipment

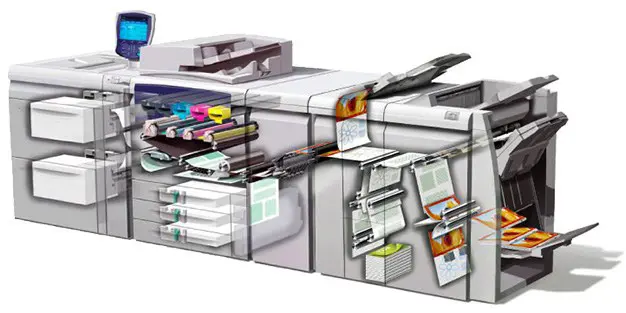

1. Sheet-fed digital printers

Output That You Can Get From This Machine

A sheet-fed digital printing machine will enable you to print on sheets of size A3 or 12 inches by 18 inches. It has paper trays in which you can stack pre-cut sheets of paper of varying thicknesses.

It uses ink toners in the form of a powder to reproduce images on sheets of paper. These machines are fast and print at extremely high resolutions.

What can you produce on this machine?

This machine will enable you to print paper posters, flyers, brochures, visiting cards, greetings and invites, letterheads, sticker sheets, certificates, discount and gift coupons, etc.

The black and white printers will enable you to print books and manuals at a very low cost.

|

Machine variants that you can choose from |

CMYK 4-colour printers – This machine will enable you to print images in full colour mode Black & White printers – This machine will only print in a single/mono colour mode. I.e. black. It is suitable for photocopying and printing books/manuals |

|

Industry-leading brands | |

|

Production capacity of the equipment |

Monthly production volumes ranging from 1.5 Lakh prints to 3 lakh prints |

|

Approximate investment required |

Rs. 25 – 30 lacs |

|

Approximate area required to operate the machine, to stock spares, and raw materials like paper stock |

125 Square Feet |

|

Approximate power consumption |

6 kW |

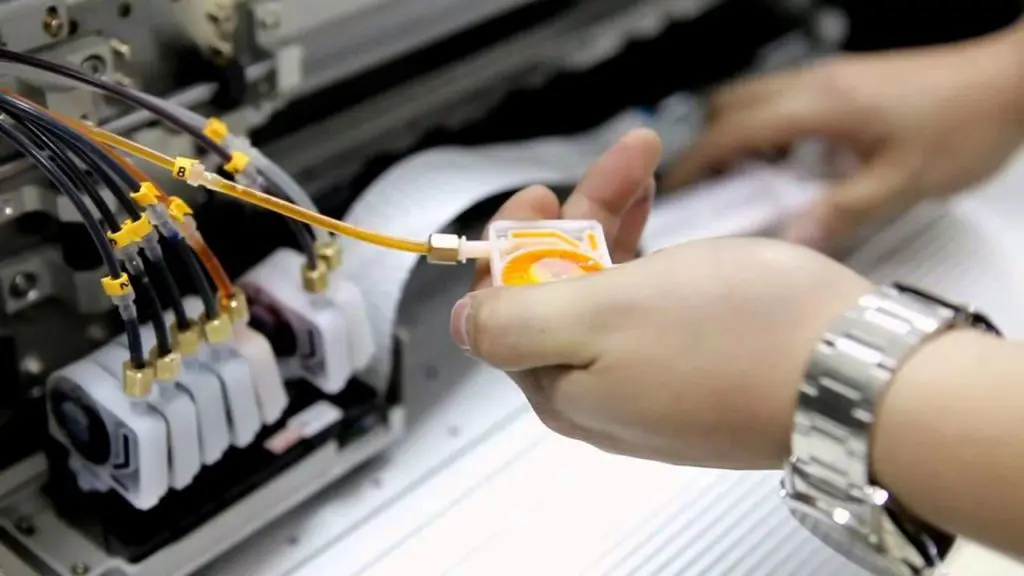

2. Roll-to-roll wide format inkjet printer

Output That You Can Get From This Machine

A wide-format printer allows you to reproduce images at an extremely high resolution on large rolls of vinyl, flex, glass films, and other banner material.

Large or wide-format printers allow you to load rolls from 5 feet to 10 feet wide. They use liquid inks, similar to an inkjet printer, to reproduce images at an extremely high resolution on these rolls.

What can you produce on this machine?

This machine will enable you to print banners, hoardings, wall prints, posters, prints on canvas, etc., kiss-cut stickers, floor graphics, vehicle prints, road direction signs, etc.

|

Machine variants that you can choose from |

Eco-solvent ink printers: Eco-solvent printers are the most widely used machines in the printing industry. They can reproduce high-resolution prints on a variety of media. Their running cost is also low compared to the other ink technologies available in the market. UV ink printers: UV inkjet prints are considered to be more robust and durable. Their prints are good for outdoor applications. Latex Ink Printers: Latex prints are a technology pioneered by HP—Hewlett-Packard. They have good resolutions and vibrant colours. We have a pretty detailed post about the various inkjet ink types, that you access here. |

|

Industry-leading brands | |

|

Production capacity of the equipment |

Look for a machine that can produce at least 150-200 square feet of high-resolution photo-quality prints per hour. It takes just too long to print large jobs on machines that are slower than this. |

|

Approximate investment required |

Rs. 10 – 15 lacs for a production-level 5-foot-wide printer |

|

Approximate area required to operate the machine, to stock spares, and raw materials like rolls of vinyl and flex media |

125 Square Feet |

|

Approximate power consumption |

1.5 kW |

3. Lamination machine

Output That You Can Get From This Machine

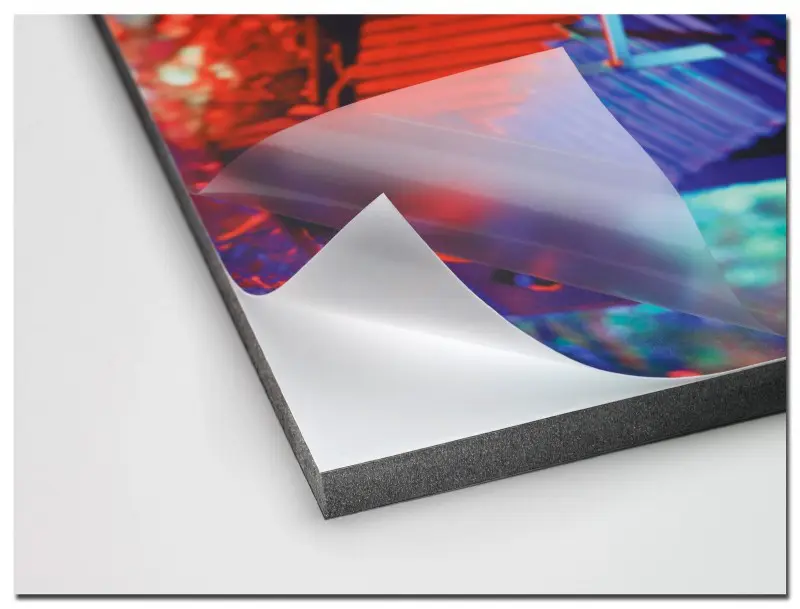

Every print is susceptible to scratches and fading. So a lamination machine enables you to coat the printed image with a protective top layer of plastic film.

Why is this machine needed?

A lamination machine is a piece of finishing equipment that will significantly enhance your prints’ life. You can even offer your clients a choice of matt, gloss, or textured finishes.

Moreover, you can use your wide-format laminator to mount/paste your prints on thick substrates like sunboard / foam sheets, acrylic or ACP panels.

|

Machine variants that you can choose from |

Hydraulic wide-format laminator: This machine is huge—5 feet wide. It can laminate full rolls of vinyl and other large-sized inkjet prints manufactured on your printer. It uses pressure rollers to evenly paste the lamination film (which has an adhesive) onto the images. Heat laminator: This machine is smaller and generally used to laminate sheets of paper of size A4 or A3. You use this machine to laminate the digital prints outputted from your colour digital printer. It uses heat to melt and fuse thin BOPP film onto your printed images. |

|

Industry-leading brands |

XL Jet is a well-known brand for the 5-foot-wide hydraulic laminator in India. |

|

Production capacity of the equipment |

The wide-format laminator should be 5 feet wide. The paper sheet laminator should be able to laminate a print of size 12 X 18 inches |

|

Approximate investment required |

Rs. 3 – 4 lacs for a 5-foot wide roll-to-roll laminator Rs. 0.5 lacs for the smaller sheet laminator |

|

Approximate area required to operate the machine to stock spares and raw materials, like rolls of lamination films |

100 Square Feet |

|

Approximate power consumption |

1 kW |

4. Sheet cutting machine

Output That You Can Get From This Machine

Your digital printer will print on large-sized A4 or A3 sheets. This machine will cut the digital prints into the final-sized flyers, visiting cards, etc.

For example, your printer will reproduce multiple copies of a single visiting card artwork on a large A3 sheet. The large sheets must then be cut into smaller individual visiting cards, and this is where the cutting machine comes in.

Why is this machine needed?

You cannot hand over a full-sized, uncut, unfinished print to your client.

Your final product, whether it is a visiting card, brochure, flier, or poster, has to be cut, creased, laminated, stapled, etc.

A sheet-cutting machine is an essential piece of equipment for achieving the required finishing.

|

Machine variants that you can choose from |

Hydraulic cutter: A hydraulic cutter is slightly more premium and uses a pressure press to hold the sheets together. Electronic press cutter: An electronic cutter uses an electrically activated spring to press and hold the stack of sheets that need to be cut. It is marginally cheaper than a hydraulic cutter. |

|

Industry-leading brands |

In India, this segment is mainly dominated by relatively lesser-known Chinese brands. However, this should not be a concern, as the machines are low-tech and require minimal maintenance. Buy your equipment from a reliable importer who can provide prompt servicing and spares in case of a breakdown. The Polar brand of cutting machines is renowned for its quality. However, this brand is pretty expensive. If you are just starting your business, an unbranded machine should suffice. |

|

Production capacity of the equipment |

A small A3+ sized cutter should be enough to start off with. Ensure you buy a cutter that can cut at least 300 – 500 sheets in a single go. |

|

Approximate investment required |

Rs. 3 – 4 lacs for a hydraulic cutter large enough to cut digital prints of A3+ size |

|

Approximate area required to operate the machine, to stock spares |

50 Square Feet |

|

Approximate power consumption |

1.5 kW |

5. Cutting & Finishing Table

What is this?

While not essential, this table makes life easy. At Orchid Digitals, we have a huge metal-framed 5-foot by 10-foot table with a thick glass top.

Why is it needed?

We routinely generate massive prints – 10 feet and larger.

These prints need to be trimmed from the edges and, at times, mounted on thick ACP or form core sheets before they can be handed over to the clients.

A large working table with a glass top aids this finishing and cutting.

|

What do I need to plan for? |

You will use blades and a cutter to cut and trim your large-sized prints manually, so make sure your table has a toughened glass top. Also, the table should be sufficiently high for people to stand and work easily. At Orchid Digitals, we have a 32-inch-high tabletop, which enables us to stand and work for extended periods without straining our lower backs. We also utilise the space beneath the table top to store a variety of raw materials. |

|

Where can I buy such a table from? |

Get a good furniture shop or carpenter to help you with this. At Orchid Digitals, we custom-fabricated our table to suit our requirements with the help of a local carpenter. |

|

Recommended size for this table |

An 8-foot wide * 4-foot deep table should work for most purposes. And if you can manage an 11 feet X 6 feet size, that’s all the more better. The max size of a sunboard and ACP sheet is 5 X 10 feet. And a large table will enable you to process the entire sheet in a single go. |

|

Approximate investment required |

Rs. 0.5 lacs |

|

Approximate area required |

100 Square Feet |

|

Approximate power consumption |

Nil |

6. Computers and software

You will need PCs to receive jobs from your clients and prepare the jobs for printing.

You will also need PCs to fire those prints onto your wide-format printers.

In addition to the Windows operating system, you will also need standard design software like Adobe (both Illustrator and Photoshop) and CorelDRAW to open, edit, and print different file formats.

|

What operating systems can you choose from? |

At Orchid Digitals, we use Windows PCs exclusively. I am not familiar with Linux systems or the Apple OS. Almost all my clients here in India use PCs as well. So compatibility is generally not an issue. |

|

What additional software will you require? |

CorelDraw, Adobe Photoshop, Adobe Illustrator, PDF Reader, MS Office, Winzip, Chrome Browser, email, etc. These days, a Canva subscription also helps, as I find my clients increasingly sharing their designs on this platform. |

|

What PC configuration should I plan for? |

Graphic design apps are resource-intensive, and if you are going to use them continuously, it makes sense to invest in high-end end computers I have had all my PCs custom-built by a local computer assembler. Most are high-end, running on Intel Core i9 processors, all with separate graphics cards. But off-the-shelf branded PCs should work for our purposes as well. Avoid entry-level laptops. Opt for workhorse PCs. |

|

How many computers do I need to buy? |

You will need PCs on the retail counter where your employees can receive, design and prepare jobs for firing onto the printing machines. You will need additional PCs to run various printing machines. You are a digital printer after all 🙂 So let’s say a minimum of 5 PCs with reasonably high-end configurations. |

|

Approximate investment required |

Rs. 7.5 lacs for 5 PCs with all the needed graphics software |

|

Approximate area required to operate the machine to stock spares and raw materials, like rolls of lamination films |

50 Square Feet |

|

Approximate power consumption |

5 kW |

7. UPS + batteries backup

The power supply in many cities in India can be erratic at times. If the power goes off, your prints stop mid-way and must be thrown off.

If there are fluctuations in the voltage, there is a risk of damage to your sensitive electronic equipment.

And so a UPS not only keeps your printing machines running during power outages but also protects sensitive equipment from electrical spikes and low/high voltages.

|

Can I opt for a lower-cost inverter? |

You will need a UPS. An inverter will not work for our purposes. Opt for a UPS with an inbuilt isolation transformer for enhanced protection. Also, there are different types of battery backups to choose from. |

|

What UPS brand should I opt for? |

The market is fractured here. While I am unaware of any nationally leading brand, each area in India has strong regional players. I use Champion UPS here in Pune, and the build is so strong that nothing goes wrong for years and years. In fact, if you invest in a good brand, you can get decades of service. Additionally, purchase batteries that require minimal or no maintenance. |

|

How much backup should I plan for? |

Calculate your power backup requirements by adding up the consumption of all your printing machines, computers, LAN systems, cameras, etc. Multiply this figure by 2 or at least by a factor of 1.5, and build your UPS to deliver this capacity. You will need this extra buffer capacity as your business grows and you add new machinery 😁 |

|

Approximate investment required |

Rs. 3 – 4 lacs for a 10 kW UPS system |

|

Approximate area required to store the UPS and batteries |

50 Square Feet |

And that’s it, folks. Our back-of-the-envelope calculations suggest you will require approximately Rs. 50 – 60 lacs to establish a mid-sized digital printing press. Of course, you may choose to commence with just a sheet-fed printer or focus your initial efforts solely on a wide-format inkjet printer. In that case, your initial investment could be lower.

Please note: I have not covered the costs of a CNC router or a laser cutting machine in the above list. You will need this equipment to fabricate 3D glow signs and logo signs from acrylic and LEDs. I am assuming that since you are just starting out in the digital printing business, you prefer to test the waters with the above equipment before expanding in the 3D signs business.

The figures above are rough estimates of the funds you need to budget for your business’s fixed assets. You will also need to consider working capital costs such as employee salaries, monthly power expenses, broadband, monthly rent for the premises, raw materials, and so forth.

What Kind of Products and Services Should I Sell in My Print Shop?

Alright, let’s talk business strategy. One of the most critical (and surprisingly underrated) questions you’ll face when starting a digital printing business is this: What on earth should I sell?

And let me tell you, folks, I wrestled with this question for 15 long years. Yep, fifteen. That’s almost two decades of forehead slapping, mistake-making, and saying to myself, “Why didn’t I think of this sooner?” So grab a coffee (or a tissue for my tale of woe) and let me save you some time.

Here’s the deal: Your digital print shop won’t become wildly successful just by churning out the usual suspects—your run-of-the-mill letterheads, visiting cards, and flyers. Don’t get me wrong, these products pay the bills, but they won’t exactly send you jetting off to the Maldives on a “printing empire” budget.

To stand out, you’ve got to embrace higher-value, harder-to-get services that make customers do a double-take and say, “Wow, you can print that?”

The Early Days: Mistakes Were Made

For the first 15 years of running Orchid Digitals, I did what I thought any sensible business person would do: I copied my competitors. I sold what they sold. And I tried to sell at a lower price point or, at the very least, at the same price point. If someone in Pune sold a colour print, I listed colour prints in my portfolio as well. And if that colour print was sold for Rs. 20, elsewhere… you guessed right. Orchid retailed it for Rs. 20 as well, if not lower.

There was no differentiation, zero value addition and no clear reason for the client to choose Orchid Digitals above the other players in the market.

I didn’t realise back then that letting the market dictate my product portfolio and pricing wasn’t helping me. It was cramping my style and my profit margins. My print shop was running, but it wasn’t exactly sprinting to the finish line.

The Light Bulb Moment 💡 What I Learned Over the Years

One day, after yet another long conversation with my accountant about “tight margins” (a dreaded phrase in the printing world), I had an epiphany. Why be the same as everyone else when you can be the Ricky Martin of printing—Livin’ la Vida Loca in your own niche? Okay, not exactly that, but close.

I decided to do something different. I finally stopped obsessing over what my competitors in the shop next door were printing and started studying them. And here’s what I found:

1. Every One of My Competitors Were Locked In A Price War With Each Other

All my competitors are locked in a brutal price war. It was like Game of Thrones, but with fewer dragons and more vinyl prints. They were all trying to win customers by offering the lowest prices imaginable. How do they do it?

- Slash prices to attract clients and drum up sales.

- Offer extensive credit terms, which, let’s be honest, increased my risk and sounded more like a trap for me.

- Offer the same services and products that everybody else was selling.

To keep the prices low, my competitors were using the cheapest and lowest-quality materials on the market. It was like trying to build a tall building with cheap, crumbling knockoff bricks that don’t quite fit together.

Take vinyl prints, for instance. These guys were offering them at rock-bottom prices using budget vinyl rolls that should probably come with a “do not print” warning. And these substandard prints creased, wrinkled and peeled off in no time at all!

Month after month, their goal wasn’t to see who made the most money, but who could churn out the most prints on their machines. It was a volume game, on wafer-thin margins, where no one makes substantial profits but only survives on a meagre take-home on a month-to-month basis

2. The No-Differentiation Dilemma

On top of the price wars, there was a serious lack of differentiation. To paraphrase a famous saying, these guys were selling what they wanted to sell, not what the market was screaming for. Here’s a vinyl banner for 40 rupees! But wait, what’s that? It’s a low-res print with colours as exciting as a gloomy, polluted, foggy evening and images that will start fading in less than a week.

So, How Do You Steal a March on Your Competitors – When the World Zigs, You Zag

You need to make yourself stand out from your competitors. Give premium services and charge a premium for the same as well. So channel your inner Maverick from Top Gun and break away from the pack. Here’s how I jazzed things up when competing in the printing and signage market:

- Stock Up on Quality: I invested in high-quality vinyl media. Yep, the good stuff. You can practically hear the trumpets when you print on it.

- Master the Art of Colour: I took a crash course in designing and colour theory and made sure to tweak my client’s images for a brighter and more vibrant print. And the result was that every super colourful print I sold brought a smile to my customers’ faces. Every. Single. Time.

- Ink-telligent Adjustments: My competitors used low-quality (and low-cost) inks. These cheap knockoff inks resulted in prints that would look dull and faded in no time at all. And so I switched to high-end, super-durable ink formulations that laugh in the face of rain and sunlight, and images that sneer at the idea of fading. These original branded inks were almost thrice as expensive as the duplicate Chinese inks my competitors were using. But an investment here made my product stand out, and paid off in spades.

- Lamination Love: Next stop, Lamination Station. All my competitors sold their prints as is. But I went the extra mile by adding a protective top coat of lamination on the printed images. This enhanced the life of the print, preventing wrinkles and ugly creases. Basically, I was telling outdoor elements like dust, scratches, and water to go find another hobby.

- A fully finished job: My competitors simply handed over a printed sheet of paper to their clients. However, I added the necessary finishing touches, including cutting, creasing, stapling, and binding. We transformed loose sheets into fully finished marketing collateral, such as a classy coffee-table book, a brochure or a flyer. My deliverables were ready to use straight out of the box.

- On-site Installation: I also assembled teams of fitters, fabricators, and installers who would go to the client’s site to install the prints and signage. My customers simply needed to provide the design files. We handled everything else, including printing, fabrication, and on-site installation. We began offering customised solutions for glass film, wallpapers, and logo fabrication. It was like waving a magic wand, where my clients just had to say “abra ca dabra’ and their entire office would get an instant makeover.

- The Superior Sale: I didn’t just sell prints; I sold finished solutions. My product was the equivalent of a Bentley in a world of bicycles. Sure, it came with a higher price tag, but it was guaranteed to fulfil my clients’ needs and ensure their complete satisfaction with the services offered by Orchid Digitals.

Listen to your client and try to understand their needs. Provide them with a solution that best fits those needs. There have been many instances at Orchid Digitals where a client has requested a more expensive print. However, if I believe that a more economical solution would serve their purposes just as well, I recommend it. Doing so may reduce your revenue, but it will enhance your goodwill.

Also, be extremely sincere and honest in what you do. If you do not have a service or product that fits the client’s needs, simply tell them so. In fact, guide them to an alternative vendor who can assist them. Being open and honest is not only morally right but also good business practice.

The Art of Differentiation and Consistently Better Service

The above section was just a few examples of how you can differentiate yourself. But these same principles can be applied to the entire range of products and services you offer.

To succeed in the game, you must do things differently from others, far better than others, and more consistently than your competitors.

Let me list some more examples of how Orchid delivers far more value addition than the other printing shops in the Pune industry.

- While others sell vinyl prints, we offer personalised wall prints and even provide installation at the client’s location.

- Other sellers print on transparent films; in contrast, we provide glass filming and installation solutions for our clients.

- Other print shops offer ordinary paper sticker prints, but we present over 20 different types of sticker solutions tailored to every conceivable use case. These include reflective stickers, metallic foil stickers, night glow stickers, transparent stickers, rainbow-hued holographic stickers, reverse pastable stickers, extreme weather stickers, and many more. This list barely begins to encompass the full range of our stickers and labels offerings.

- While others sell simple glow signs, we first seek to understand our client’s requirements, advising and suggesting the best options available. We assist them in making the right choices regarding material, dimensions, LEDs, placement, and installation.

3. It’s Not The Machine, But The Man Behind It!

Here’s another nugget of wisdom that took me way longer to learn than I’d care to admit: your customers don’t give two hoots about the fancy machinery you’ve got tucked away in your printing shop. Seriously. They’re not going to pull out their magnifying glass and say, “Oh wow, was this printed on a Konica or an HP?! Tell me all about it.”

What they do care about boils down to just three things:

- Is the job done on time?

- Does it fit into their budget?

- And is the quality genuinely impressive, even “Naani ke haath ka khaana” kind of impressive?

When I first started my digital printing business, I was borderline obsessed with my shiny, oh-so-expensive machines. They were like my pets. I’d brag to clients about them as if I were introducing a prized racehorse: “This visiting card? Printed at 1200 DPI on a top-of-the-line Konica!” Or, “This flex hoarding? You’re looking at Mimaki UV inkjet excellence, my friend!”

But guess what? My clients had zero interest in whether my printer was named Mimaki or Mickey Mouse. To be honest, I could’ve told them I had dwarves in my basement hand-painting each piece, and as long as the print was stunning, timely, and within budget, they wouldn’t bat an eyelash.

What Your Clients Actually Want

Let me break this down for you. Customers aren’t here for your tech specs; they’re here to have a problem solved. So when you’re starting a digital printing business, focus on addressing these golden complaints:

- Does the print solve their problem?

Think of a jaw-dropping custom wall branding that transforms their dull workspace into something straight out of an architectural digest. Is that boring wall about to become the Mona Lisa of office décor? Perfect—you’ve nailed it.

- Is your solution reasonably priced?

Sure, custom designs and prints can’t be dirt cheap. But your clients shouldn’t feel like they need to sell a kidney for the same either. Clients want value for money. So give them Picasso-level prints on an IKEA budget.

- Will it be done before their Aunt Kamla’s deadline?

If your client says there’s an important visitor coming on Tuesday—and it’s Sunday—rolling up your sleeves to deliver the goods in one night will practically canonise you in their eyes. Do this, and the next thing you know, they’re recommending you to their entire LinkedIn network.

Bottom line? Clients don’t care how you bring the magic—whether you’re rocking a fancy printer or channelling Harry Potter. They only care that you bring it.

Drop the Machine Obsession: A PSA for Newbie Print Vendors

Let’s talk rookie mistakes, shall we? When you’re starting out, it’s tempting to spend big bucks on the latest, shiniest machinery that looks like it’s auditioning for a sci-fi movie. But here’s the truth: you don’t need to go all Tony Stark with the gear in your first year (or even your second).

If you don’t have the fancy equipment yet—or the budget—you can always outsource print jobs. Say it with me: outsourcing is not cheating. It’s problem-solving for your clients, and that’s all they care about. Think of it as borrowing your friend’s Netflix password—it’s a win-win without the upfront cost.

If your client is looking for just 100 brochures and you don’t have a ₹ 50 lac digital press, outsource that job to someone who does. PS: Our address is in the Contact Us Page of this website 😅

Once your business starts gaining traction (and you can make it rain profits), then you can reward yourself with that high-end printer. Until then, focus on delivering stellar service.

And oh yeah. After a big win, maybe treat yourself to your own Netflix account and return that password you have been borrowing all year. 😉

So, How Do I Decide Which Brand of Machine to Buy?

Ah, the million-rupee question—”Which printer is the one?” Should you swipe right on HP, ghost Canon, or send love letters to Roland DG? It’s a question I hear all the time, and honestly, it’s like asking whether Shah Rukh Khan is a better romantic hero than Ranveer Singh. Spoiler: they both rock in their own way. And when it comes to printers, the truth is equally anticlimactic—it doesn’t matter all that much.

Here’s why: When you’re buying from globally renowned brands—think HP, Konica, Mimaki, Roland DG, Canon, Agfa or Ricoh—you’re essentially saying yes to top-notch engineering, stellar output, and the digital printing equivalent of a “chef’s kiss.” I’ve been in the trenches for years with machines from these brands, and guess what? They all deliver prints that could make Picasso shed a tear.

Case in point: I’ve worked with both Mimaki and Roland wide-format printers for years, and I’ve gone through a couple of HP Designjets as well. Not once has a customer burst into my office demanding a reprint because my Mimaki JV300 wasn’t doing justice to their artwork. It just doesn’t happen.

Choosing between these machines isn’t about questioning quality—it’s more like choosing coffee over tea at Starbucks—similar buzz; different flavours.

There are technical differences between these offerings, and if you need to do a deep dive into the same, do take a look at this post here.

Choosing the Right Printer – Car Metaphor Incoming!

Think of it like buying a car. Whether you pick a Maruti or a Hyundai, both will get you from your couch to the nearest pani puri stall without drama. Sure, one might have rear AC vents or better mileage, but does that change the sheer joy of snack runs? Nope.

Translation: A Konica or a Roland DG will both give you great prints with minor feature differences, and both will cost roughly the same. Buy what suits your budget, your space, and (if we’re being honest), trust your gut feeling.

Pro Tip: Visit Trade Exhibitions—The Candy Store for Printing Nerds

Now, before you walk into a printer showroom with stars (and confusion) in your eyes, let me let you in on a secret. Trade exhibitions are your go-to paradise.

These are where the biggest names in the business—HP, Mimaki, Roland DG, Mutoh, and a bunch of others—all congregate with their latest shiny gadgets to fight it out against each other and make you gasp like it’s the series finale of Game of Thrones.

These exhibitions let you:

- Compare Products in Real Time: Forget scrolling aimlessly on Google. Here, you can touch, feel, and see printers in action. Think of it as a mega demo day—except with less PowerPoint and more pizzazz.

- Test Your Artwork: Bring your own design files! Seriously, pack a USB stick like it’s a weapon of mass creativity and get your image files printed on different machines. You’ll quickly be able to compare print outputs from all the top brands.

Why You Have to Attend These Events

Exhibitions are less about the machines and more about levelling up your knowledge game. You’ll see cutting-edge tech, meet like-minded printpreneurs and get tons of information from the machine sellers.

You will leave feeling like you’ve just binge-watched a season of The Mandalorian—you’re not quite the same person afterwards.

And hey, don’t just stick to local events. If you can swing it, pack a bag and hit those national or even international trade fairs. Sure, you might come back jet-lagged, but you’ll also bring home enough insights to make your competitors feel like they’re still printing in black and white.

After-Sales Support: The Unsung Hero of Printer Shopping

Okay, picture this: You’re on the hunt for the perfect digital printing machine—your soon-to-be partner in print crime and the shining star of your print shop. You’ve done the research, stared at spreadsheets of specs until your eyes crossed, and even watched YouTube tutorials at 2 AM. But here’s the curveball no one tells you about: What happens when your machine decides to throw a tantrum?

Spoiler alert: It will. Even the fanciest wide-format inkjet or sheet-fed digital printing press will have its off days. And when that day comes, you’ll want to have a service guy’s number on speed dial. You will need someone to come over and service your machine faster than a pizza delivery boy. That’s why after-sales service is not just a “nice-to-have” but a full-on must-have.

Why After-Sales Service is the Maruti of Machine Buying

Why does Maruti Suzuki dominate the car game in India? Ask any kid on the street, and they’ll tell you it’s because you can find spare parts and mechanics in every big and small town of India. The same principle applies to printing machines—it’s all about availability and support.

Your machine could be the crown jewel of your digital printing biz, but if it conks out and there’s no one within 500 kilometres to fix it, you’ll end up trying to sell your kidneys to fund the repairs. Trust me, I’ve been there. Printing equipment is basically a needy toddler: it demands attention, regular maintenance, and the occasional “reboot” to keep it from losing its marbles (or print heads).

My (Painfully) Real-Life Printer Horror Stories

Since we’re pals now, lemme spill the beans on a few of my machine mishaps—because nothing teaches better than learning from someone else’s trainwreck, right?

The HP Designjet 5500 Debacle

I thought I was being clever, snapping up a second-hand HP Designjet 5500 for a steal. But did I have an AMC (Annual Maintenance Contract) with the company? Nope. And as Murphy’s Law would have it, the print head decided to die right in the middle of a mega print job. I had no spare parts and no real plan. Three days and an embarrassing number of “urgent deadline extensions” later, I finally sourced the part. Moral of the story? Don’t play Russian roulette with your machine’s health.

The British Diva Cutting Machine

My Intech SC 5500 cutting machine, shipped straight from the UK (fancy, right?), stopped working during a critical project. Turns out, its motherboard was fried, and guess what? It’s the only one of its kind in Pune—heck, maybe even in the country. Spare parts? Non-existent. A local repair guy? Dream on. That machine turned into an expensive dust collector for a whole month while I scrambled to find a solution. PSA: Stick to brands with a service centre on the same continent as you.

The ₹2,50,000 Diwali Disaster

Ah, my gorgeous Roland VS-540 print-and-cut machine. It was an engineering marvel for its time—and then a company engineer forgot to park the print heads properly before we shut shop for Diwali. A week later, we came back to dried-up print-heads that cost me over two and a half lakh rupees to replace. Yep, you read that right—the Diwali sweets turned to ashes in my mouth when I saw the repair bill for that one small mistake.

The Golden Rule: Go Local or Risk Tears

Here’s the thing: if your vendor is located four time zones away, getting spare parts and service will feel like a long-distance relationship—it’s never as smooth as you dream it’ll be. Always, always choose a vendor who has a local office or, at the very least, a branch in your city. This ensures that routine maintenance or last-minute emergencies don’t turn into a Netflix documentary about catastrophic failures.

And if you’re based in a smaller city without many suppliers, look for companies that go the extra mile (literally) to deliver on support. Reliable service engineers should be just a phone call away—kind of like your friendly neighbourhood samosa guy, but for printers.

TL;DR: Don’t Buy Just the Machine, Buy the Backup Team

Even the “best” printer isn’t the best if it doesn’t come with solid service and support. It’s not just about running a B2B printing business or acing signage printing jobs—your sanity is on the line, too. Your machine breaking down mid-job should feel like a minor hiccup, not the plot of a disaster movie.

So, do yourself a favour: Before hitting that “buy” button or cutting that ‘advance’ cheque, ask the hard questions about after-sales service. Does the machine vendor have enough engineers and support staff? Are these guys present locally? Are they competent enough to solve any problem that might crop up?

If your machines decide to go rogue, you’re gonna need more than a wrench and a prayer to get through it. Consider your diligence in this matter an investment in your peace of mind—and trust me, your future self will thank you.

Credibility: Trust Before You Bust!

Now, let me share with you a tale of my personal machinery wisdom. I have on my mind something known as the “Rule of 10”! And here’s what it says: don’t buy equipment from vendors who’ve installed fewer than ten machines in your city. Yup, you need your vendor to have quite the history like Captain America’s shield – strong and reliable.

Your vendor should be more established and well-trusted in the printing industry. The company should have several proven installations in your vicinity. Moreover, the machine company should also have a substantial setup, complete with spare parts, raw materials, and a staff strength more numerous than mosquitoes in the monsoon season.

When a printing machine model is newly launched, it has numerous bugs. And by the time it goes through a few generations, these bugs are usually resolved.

Therefore, verify that the model you intend to invest in is already installed at various locations. Obtain a review from current owners regarding the machine and, more importantly, the supplier, before you spend your hard-earned money on that equipment.

Calculate Costs: Count the Expenses Like a True Scrooge McDuck

Imagine you’re faced with two cars. Car A costs ₹100 and gives you 5 km per litre of petrol. Car B costs ₹200 but stretches that litre through 15 km. Which would you choose – the guzzler or the saver? Even Iron Man would go for Car B because, after saving the world from aliens, saving moolah is the next best thing!

Like the fuel in the car, every printing machine also has a significant run cost. These costs include:

- The cost of the inks that are consumed while printing an image.

- The consumables (like maintenance kits) that have a set, specific life after which they have to be replaced

- The power consumption required to run the machine. Some machines have driers and built-in heaters. And if the inks don’t dry quickly, heating the print can significantly affect your monthly electricity bill.

Therefore, consider the running costs of the equipment as a crucial factor in your ‘buy’ decision. This factor, more than any other, will significantly impact your profitability and competitiveness in the printing industry.

Additionally, do not rely solely on the claims made by the company’s marketing representative. For instance, if the representative asserts that the running cost of this machine is rupees 5 per square foot, plan for rupees 10 as the actual real-world cost per square foot when preparing your budget. The seller’s cost estimates are based on ideal world scenarios. And the real world is anything but ideal.

Always plan for the worst and hope for the best.

If the vendor claims that the life of the print head is 3 years, consider the economic implications for your profit margins if the printhead fails within 1 year.

I am not suggesting that printing machine vendors are dishonest or misrepresent facts. I am simply stating that their estimates are based on ideal working conditions, and these estimates often fail in the face of real-world challenges.

Versatility and Multi-function Printers: The Swiss Army Knife of Digital Printing Machines

Alright, let’s play a quick game of Would You Rather. Imagine this:

Machine A gives you jaw-dropping prints on vinyl—like the kind where people stop mid-stride to say, “Wow, who printed THAT?” But… that’s about all it does. It doesn’t multitask, barely lifts a finger, and takes no initiative in its free time.

Machine B, on the other hand, still delivers great vinyl prints. But, here’s the kicker: it also kiss-cuts those prints into neat little stickers, ready for your client to peel off and slap on their laptops, notebooks, or random lampposts around the city.

Which one would you pick? Obviously, you’d swipe right on the machine that’s versatile, multitasks like a pro, and basically earns its keep. Trust us, in the world of digital printing, versatility isn’t just a bonus—it’s a necessity.

So, what should you look for in these overachieving printing machines? Let’s dive in!

Add-on Features That Make Your Printing Machine Shine

1. Can Your Machine Handle Thick Paper? Like, REALLY Thick?

Most entry-level printers can handle 250–300 GSM card sheets without breaking a sweat. But what about those clients who slide a box of fancy wedding invites across your counter and expect you to work miracles on 400 GSM textured cards? Cue the sweat beads.

If your machine can handle thicker papers, you’ve just unlocked a whole new level of business opportunity.

Think premium photo albums, luxury packaging boxes, and yes, those fancy wedding invites that come with enough glitter to blind a unicorn.

Take a look at this premium menu card we created for a luxury restaurant in the form of a coffee table book. The pages inside are super-thick (read thick as a plank of wood) and bound in a lay-flat method. When opened, the book gives off that luxurious look and feel.

2. Textured Paper: The Fancy Stuff for Fancy Jobs

Sure, most digital printers will churn out beautiful prints on coated or uncoated papers—and honestly, that’s enough for 90% of your clients. But for that elite 10% (you know, the ones sipping lattes and specifying Pantone colours), you’ll want a printer that can handle textured paper like a dream.

From embossed visiting cards to art reproductions that look like they belong in a gallery, textured printing opens the door to premium products—and premium pricing.

3. Automated Collating and Stapling: Saving Your Sanity, One Book at a Time

If you’re cranking out books or photocopies at breakneck speed, a machine with an inline collator and stapler will feel like Bezos-level tech. Imagine never having to manually staple 100 copies of a 500-page booklet while questioning your life choices. This feature will single-handedly save your time, energy, and probably a piece of your soul.

4. Plotter Cutting Blade: The Unsung Hero of Sticker Land

Ah, stickers. They’re small, sticky, and ridiculously popular in every business niche imaginable—from embossed stickers for branding swag to laptop decals. If your wide-format printer comes with a built-in plotter cutting blade, you can shape-cut your vinyl prints into literally any design your client dreams up. Circles? Check. Stars? Sure! That weird llama shape? Why not—go nuts!

Fun fact: At Orchid Digitals, our print-and-cut feature has saved us countless hours during sticker production (and kept my caffeine intake manageable…ish). I simply cannot function without my inline cutter—it’s like the Batman utility belt of digital printing.

5. Weatherproof Inks: Because Mother Nature Has Zero Chill

Picture this: You send a beautifully printed outdoor hoarding to your client. Two days later, it rains, and your stunning masterpiece looks like something straight out of a post-apocalyptic movie.

Here’s where weatherproof inks come in. HP’s latex inks, for instance, boast about their ability to survive the elements without needing lamination. Meanwhile, UV inks are the Hulk of the ink world—strong, durable, and ready to take on harsh sunlight, rain, and whatever else Mother Nature throws at them.

Why Versatility Matters (and Why It’s Your Golden Goose 🥚)

Investing in a multifunctional digital printing machine isn’t just about having more features to brag about (although, let’s be real, we all love that). It’s about giving your clients solutions they didn’t even know they needed—and letting every feature of your machine rake in new revenue streams for you.

Want to crush your competition?

- Step one: Offer what they don’t.

- Step two: Upgrade your machines so you actually can.

- Step three: Say “Yes, we can!” to every curveball request your clients throw your way.

In the end, it’s simple math: More functions = More services = More money in your pocket = (Hopefully) enough coffee to binge-watch the Lord Of The Rings trilogy.🚀

And since we are talking about curveball requests, take a look at this demand from a client that resulted in the world’s most unique invitation card.

Ease Of Use. The Implications Of Buying The Cheaper Chinese Option

Alright, let’s talk about something that might save you from a few gray hairs (or a lot of shouting matches with stubborn machinery). If you’re dipping your toes—or diving headfirst—into the world of digital printing, the equipment you choose will either be your best friend or that annoying “friend” who only shows up to borrow money and eat your snacks.

So brace yourselves, folks, because we’re about to have the talk about branded digital printers vs. their more… budget-friendly offspring, the unbranded Chinese knockoffs. Spoiler alert: It’s kind of like choosing between a sturdy battle-ready tank and a tricycle made of twigs.

Meet the Rockstar Brands

Let me drop some names that are basically the Beatles of the printing world—Mimaki, Roland DG, HP, Agfa, Epson, Canon, Ricoh. These giants don’t just print pretty pictures; they print peace of mind. They’re built to last, their features save you time (and sanity), and they come with customer support that actually picks up your calls. These machines are a joy to work with—until you look at the price tag and consider selling a kidney. But hold on to your internal organs for a second!

Enter: The Siren Song of Cheaper Options

Now along comes unbranded Chinese machinery, winking at you with prices that are up to 40% lower than the branded machines listed above. “Come on,” these machines whisper, “you’ll save so much upfront!” And sure, saving a few lakhs of rupees sounds pretty fantastic at first… until you realise you’ve essentially bought a beautifully wrapped headache factory. Yep, been there, done that, and boy, do I have some stories.

The “Oh No, What Have I Done?” Moments From My Career

Here’s why my short-lived fling with cheaper machines turned into a nightmare faster than you can say “reprint”:

1. Software Interface That Makes Excel Look Like Fun

Most branded machines come with intuitive software—think Apple-level sleekness. On the other hand, unbranded Chinese machines have interfaces so tricky, you’d think you’re trying to decode the scripts from The Matrix.

Their software (like the RIP—Raster Image Processor) or control panels are extremely difficult to use. The software is not intuitive, and most of the options cannot be understood by the machine operator.

2. Maintenance: The Never-Ending Saga

My Mimaki UV printer features an auto-cleaning system. The print heads automatically cycle cleaning fluids throughout the machine to keep it in pristine condition. This cleaning fluid prevents clogging and jamming. The machine performs this cycle automatically every hour or so, ensuring that I receive spotless prints straight out of the machine each time.

Conversely, my Chinese wide-format printer lacks auto-cleaning functionality, requiring all cleaning to be done manually, which underscores my frustration. Although I saved money on the initial investment when purchasing the equipment, I now face the daily dilemma of maintaining this unbranded machine by hand. Additionally, if I forget this maintenance, I risk incurring a significant loss if the print heads become clogged and need to be replaced.

3. Calibration Woes

My Roland Eco Sol printer is equipped with a sensor that automatically calibrates the length and width of any printed image, so I achieve the correct dimensions (with mm to mm accuracy) for each and every print job. This feature is important because if you set out to print a 40-foot banner and end up a few inches short, you need to throw away the entire print job (and your sanity).

But with the auto-calibrator constantly checking the size, I never have to worry about such a disaster taking place in my unit.

In contrast, my Chinese wide-format machine requires manual calibration. Moreover, this needs to be done very frequently. If I neglect this calibration, I may end up with an image that is inaccurate in its dimensions, leading me to dispose of fully printed jobs and reprint them anew.

4. Color Accuracy = Hit or Miss

My Konica digital printer incorporates an inline colour calibrator that verifies colour accuracy for every print processed in the machine. If the calibrator detects even the slightest discrepancy in the printed colours, the ink levels are instantly adjusted to ensure I receive the optimum output for every single print job.

So when I fire a 1000 copies of the same image on my digital press, the colours of the first print and last are exactly the same!

Many non-branded digital printers do not include this feature, necessitating manual checks for colour accuracy.

The problem with this process is that by the time you check the colours, it’s already too late, and the entire job has been printed. If you catch any errors in the print quality at that point, you can only discard the entire job and reprint everything once again. This results in significant monetary losses and production delays.

The Silent Killer: No Support, No Spare Parts

Here’s the unsung hero of branded machines—support. When something breaks down (because, let’s be real, that’s inevitable), you need a support team ready to swoop in like Avengers technicians and save the day. With unbranded machines, you’re on your own, Googling for spare parts and waiting for weeks for a part from China that might almost fit.

Imagine having to halt your entire business because you can’t find a tiny, essential component. Yeah, fun times.

The Penny-Wise Trap

There’s a saying that fits here perfectly: “Penny wise, pound foolish.” Trust me, I fell for the initial discount sparkle thrice, and now I preach the gospel of branded machines like a converted soul. Sure, they might cost a little extra upfront, but the savings in time, frustration, and maintenance costs are worth their weight in gold. 🎉

What Kind of Software Skills Will You Require To Run A Digital Printing Shop?

If you’re thinking about diving into the fabulous world of digital printing, you’re going to need to channel your inner tech wizard. No magic wands here, just some solid computer skills and a decent understanding of graphics software. Consider yourself in Hogwarts for printers—minus the robes and epic duels, unfortunately.

See, in a digital print shop, you never know where your files are coming from. It’s like the presents you receive at your surprise party, where the gifts can be anything from gold to… well, socks. You might get a sleek Adobe Illustrator file, something quirky from CorelDRAW, or a masterpiece out of Photoshop. Recently, we’ve been seeing a lot of designs made on Canva and Adobe Express. Heck, we even get print files whipped up in PowerPoint. Yes, PowerPoint. You heard that right.

But the important thing is, irrespective of the file format (or the software that the design is created in), you need to deliver the job.

This means you need to have a working knowledge of several design software programs. Not only should you be able to print from these applications, but you should also be able to apply tweaks and adjustments from within these applications before firing the job on the machine.

Now, before you panic and start dreaming about a life as a llama herder, take a deep breath.

You don’t need to transform into a graphic designer overnight magically. But you will need some basic know-how to fix or edit the files that land in your lap. Sometimes that means tweaking colours till they pop or adjusting layouts until they’re just right.

You’ll need to export your client’s art to the printing machine, making sure it’s in the right file format. Whether it’s .jpg, .pdf, .eps, or .tiff, you’ll have to master the art of the export like a techno-samurai. Each piece of printing equipment has its own quirks and controls, like a moody teenager, and yes, you’ve got to get chummy with them too.

Remember, your printing machines are your partners in crime. They can tweak your print jobs to deliver vibrant, colored outputs in high resolution. Familiarise yourself with them, understand their software controls, and soon enough, you’ll be producing prints so stunning, they’ll make Picasso wish he had a digital printer.

So, grab your virtual toolkit, get your software game strong, and let’s make some art that would make our ancestors tear up with pride. (Or at least, impress your clients enough to keep coming back for more!) 🌟

What Kind of Business Skills Do You Need to Start a Printing Shop?

There’s something wildly satisfying about turning a blank sheet of paper (or vinyl… or canvas… or glass film) into a visual masterpiece. But before you start dreaming about designing jaw-dropping vehicle wraps or signage that lights up like Times Square, let’s talk about business management skills.

The Backstory: My Teenage Training Montage

Picture this: a scrappy teenager sitting in his father’s paper trading shop, learning the ropes of business basics like stock management, billing, and customer sales. Yep, that was me. It was less The Wolf of Wall Street and more The Intern—except the intern was unpaid and ate most of the shop’s snacks.

Don’t get me wrong, those lessons were gold. But transitioning from selling paper to running a full-fledged digital printing business? That was like jumping from riding a tricycle to piloting a Formula 1 car. The learning curve was real, and spoiler alert: you’ll need to pick up a few more tricks along the way. Let me break it down for you.

1. Billing: The Art of Controlled Chaos

Billing in the printing business is NOT for the lazy (or the faint-hearted). Unlike a trading business, where the bill is a quick one-liner (“Paper, 500 sheets—done”), printing involves layers of complexity that would make even a software engineer rub their eyes.

Here’s the deal: When clients order a signboard, they’re not just buying one item. They’re buying a Frankenstein of components—metal sheets, LED lights, acrylic, ACP panels, labour, on-site installation, and probably a partridge in a pear tree.

The billing system you implement must reflect all of these elements.

Furthermore, one item can have several variants. A brochure may consist of four pages, eight, twelve, sixteen, twenty-four, or more. A flex banner can be customised to any size the client requires: two feet by three feet, four feet by five feet, three feet by five feet, etc.

Your billing system must be flexible enough to accommodate these details and calculate the total selling price accurately.

2. Sales: It’s Not Just About Closing Deals—It’s About Closing Loops

At Orchid Digitals, sales are a multi-step thriller. Think Mission: Impossible, where each phase builds on the next. Let me walk you through it:

3. Accounts & Statutory Compliance: GST, TDS, PT, VAT, OMG!

If you’re anything like me, “statutory compliance” sounds like something out of a legal snore-fest (and about as fun). But keeping your accounts in order is non-negotiable. Between GST, VAT, TDS, and all the other three-letter financial nightmares, you’ll need an accounting system that’s smarter than your smartphone. Bonus tip: Don’t skimp on this—it’s not cute when the tax department sends “friendly letters.”

Your accounting system will also track the amounts due from your creditors and receivable from debtors, and this is essential for maintaining your liquidity.

4. Marketing: Shouting (Creatively) into the Void

Here’s the honest truth: You could be the Gandalf of the printing world, but if your clients don’t know you exist, they’re not buying squat. Marketing is key, and no, you can’t just rely on “word of mouth” unless your clients are town criers from the 1800s.

At Orchid Digitals, we’ve turned to visual platforms like YouTube and Instagram to market our products. A quick 30-second video showing the stunning difference between matte and glossy finishes converts the client super fast. Whether it’s Instagram reels or a slick website with killer SEO, there’s no excuse to stay hidden.

Networking, online ads, social media, etc., are all tools that will help you market your products, and a working knowledge of these will assist you in increasing your sales.

5. Inventory & Materials Management

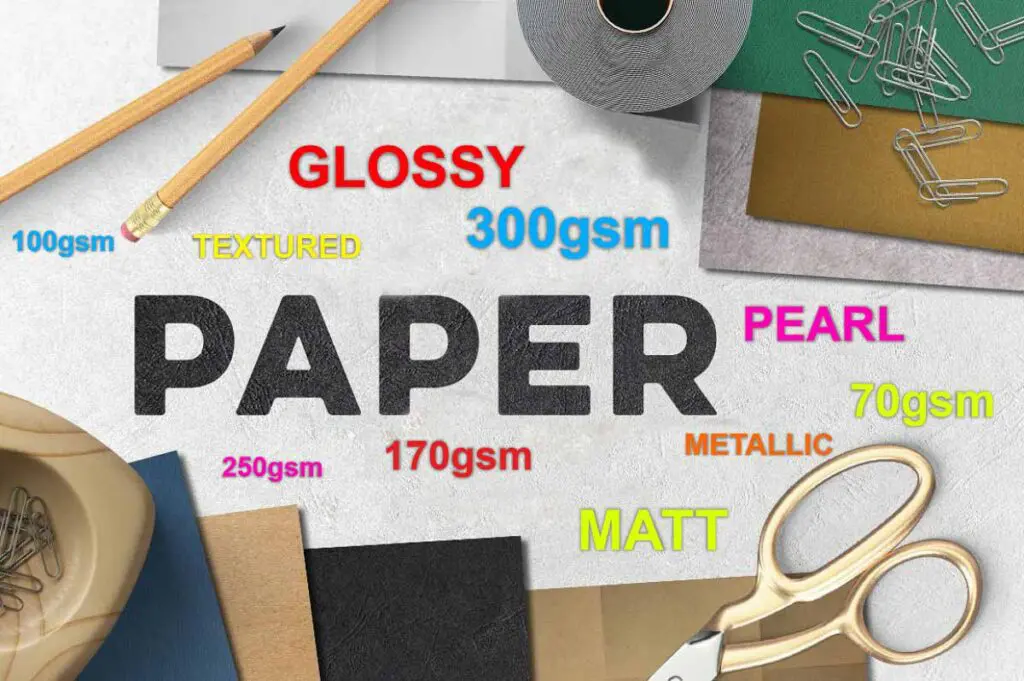

Every machine you have will have a variety of different media options. For example, your digital printer can print on sheets of paper that are 100 GSM, 130 GSM, 170 GSM, 250 GSM, and 300 GSM thick. So, you need to stock reams of paper in each of these thicknesses. It also prints on A4 and A3-sized sheets.

Stocking two different sizes for each thickness will double your inventory. And then come textured paper variants like leather texture, linen texture, canvas texture, etc. Metallic finished paper, like gold and silver cardsheets. Each of these variants will push up your inventory.

The situation is the same when you need to stock rolls of media for loading onto your wide-format printing machines. These machines accept rolls of 3 feet, 4 feet, 5 feet, 6 feet up to 10 feet wide. Here again, you have to stock different materials like rolls of vinyl, flex, canvas, etc. in all of the above sizes.

You need a robust inventory system in place to stock, track, and reorder each of the above items in your printshop.

6. Human Resources: Good People Make Good Prints

Here’s the thing: Your shiny new digital printer isn’t worth squat without skilled operators. Training is essential. Your employees need to know how to navigate design software (Adobe Illustrator, CorelDRAW, Canva) and handle the machinery without panicking worse than contestants on Masterchef.

Oh, and once trained, treat your employees like gold—because losing a skilled operator during peak printing season hurts more than a paper cut from 300 GSM card stock.

One Head, Many (Exhausted) Hats

At the beginning, you’ll wear so many hats, you might accidentally start a hat shop on the side. From sales to marketing to accounts, it’s all you. But hey, that’s part of the adventure.

Eventually, as your business grows, you’ll get to delegate these roles to teams, departments, or that one super-efficient employee who somehow runs on caffeine and pure willpower. Even then, it pays to understand how each piece of your print-shop puzzle fits together.

So, dive into the world of vibrant banners, eye-popping stickers, and custom signage solutions. Trust me, it’s a wild ride—but also one of the most rewarding ones you’ll ever take. 😉

Conclusion: The Digital Printing Saga – A Spoonful of Joy and a Dash of Gratitude

Alright, so here’s the tea—or coffee, depending on your caffeine allegiance. I’ve had quite the career journey before finding my true calling in the digital printing business. From hustling at a retail trading shop to working in a corporate environment and even rolling up my sleeves to fix cars at a garage, I’ve seen it all.

But, honestly, none of those gigs lit me up the way my digital printing business has. Yeah, it’s kind of like finding your true soulmate, except, you know… it’s a 1200 dpi printer instead of a rom-com-worthy life partner. 😁

After 25 years (yes, I’ve been in this game longer than Ross and Rachel’s “will-they-won’t-they”), I can confidently say this business has brought me immense satisfaction and joy—and not just because I get to boss around fancy machines all day.

Every day is a new adventure, and clients never fail to keep me on my toes. One day, someone’s asking me to brand an entire airport (no pressure, right?), and the next I’m whipping up dreamy wall murals with multiple depths, design elements and scores of different materials. Oh, and did I mention that my current project is an LED acrylic sign shaped like a spoon? Yes, a spoon! If this doesn’t scream “creative playground,” I don’t know what does. 😂

Whether I’m solving a client’s tricky marketing problem or making a glow signboard that turns heads faster than a Diwali sale, I know one thing for sure: deeply satisfying work hits differently. When a client walks away with the perfect print solution and a smile wide enough to rival Joey Tribbiani’s “how-you-doin’” grin, you can’t help but feel like a rockstar.

And let me tell you, if you’re the creative type—the kind who finds joy in turning ideas into tangible works of art—this business is like stepping into Disneyland (minus the Mickey ears). Sure, it’s challenging. Sure, it requires a decent chunk of cash upfront to start (those nifty printing machines don’t buy themselves, unfortunately). But the rewards? Oh, they’re sweeter than chocolate on a bad day.

Here’s the kicker: it’s not just about the money or the comfortable lifestyle (although those don’t hurt, let’s be honest). It’s about showing up to work every day, pouring your heart into crafting something unique, and feeling like you’ve cracked the code to a little slice of happiness. And isn’t that ‘happiness‘ what we’re all chasing in the end?

Share

Looking for any specific product?

Drop us a line. Send us your query. And we’ll get back to you with solutions and answers.

Mitesh Sanghani

Mitesh lives, mostly for Saturdays.

But when forced to work, you’ll find him heading Orchid Digitals – a printing press in Pune.

If it’s an emergency, try looking for him in the hills behind his house. You’ll almost certainly find him… lazing under a tree, with a book in hand.

Similar Products & Blogs

All our Blogs

This is a section packed with useful knowledge on digital printing and its aspects, interesting printing case studies, and ideas, guides, and tips & tricks on marketing and branding.