Sunboard / Foam Sheet Prints. Thick, Rigid Yet Light-weight.

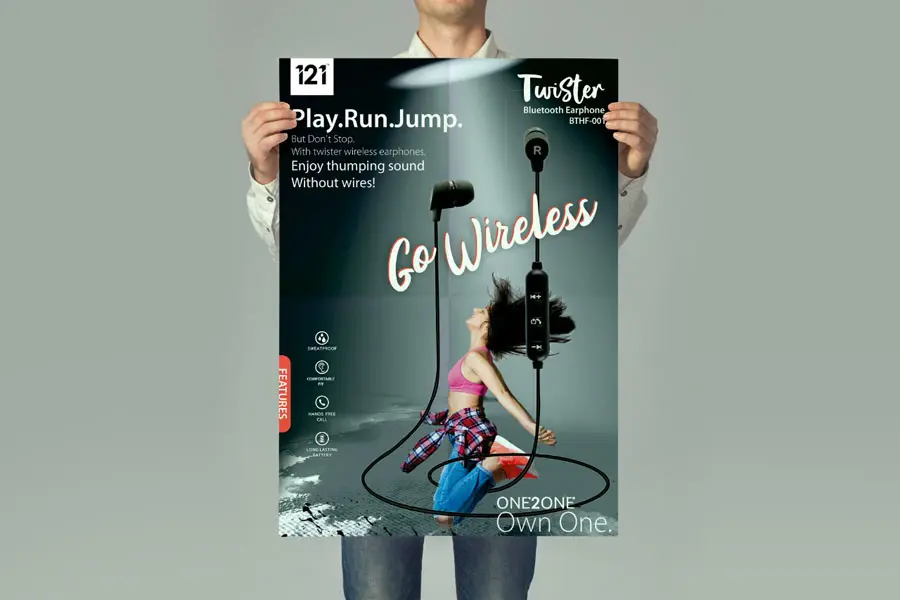

Communicate Your Message In Style Using Smooth, Flat & Rigid Posters

- Thick rigid and smooth sunboard poster prints

- Light in weight, and on the pocket

- Impressive photo quality prints on 3 mm and 5 mm thick PVC sheets

- Perfect for displaying product images, model pics, charts and photographs

- Used for branding in malls, retail stores, offices, hospitals, restaurants, etc.

- Shipping facility available in Pune. We can also ship bulk orders of this product across the country.

- Stunning sunboard prints starting from ₹70 per square foot

Share

Sunboard / Foam Sheet Prints – Detailed Description

Marketing, to a great extent, is all about putting your best foot forward. To convince your clients, you have to present an enticing picture – of your brand, your products, and even yourself.

At Orchid Digitals, we have many excellent products to help communicate your business offerings and products. And one of our best selling solutions is printed foam sheets. This product is also popularly called sunboard / foam board prints.

What Is A Printed Sunboard?

A printed sunboard is essentially a poster that is thick, rigid, flat, very smooth and extremely light in weight.

Large-sized posters are manufactured in print-houses on huge, wide-format machines. These wide-format printers reproduce images on giant rolls of paper or plastic (printable vinyl). But both paper and plastic are flexible. Vinyl prints are generated in a roll form and have no rigidity or intrinsic strength.

You need something to ‘solidify’ the print and give it a better finish. Imagine pasting a loose sheet of paper in a high-end shopping mall. It is going to look pretty shabby.

To resolve this issue, we mount the printed vinyl poster on a thick and rigid PVC sheet. The industrial term for this sheet is a low-density polystyrene board.

But don’t let this term scare you. A foam board is nothing but a rigid sheet of plastic with a smooth surface that enables high-quality image reproduction.

As a buyer, you should be aware of the following characteristics of our printed sunboard sheet.

Vinyl Sunboards Are Thick

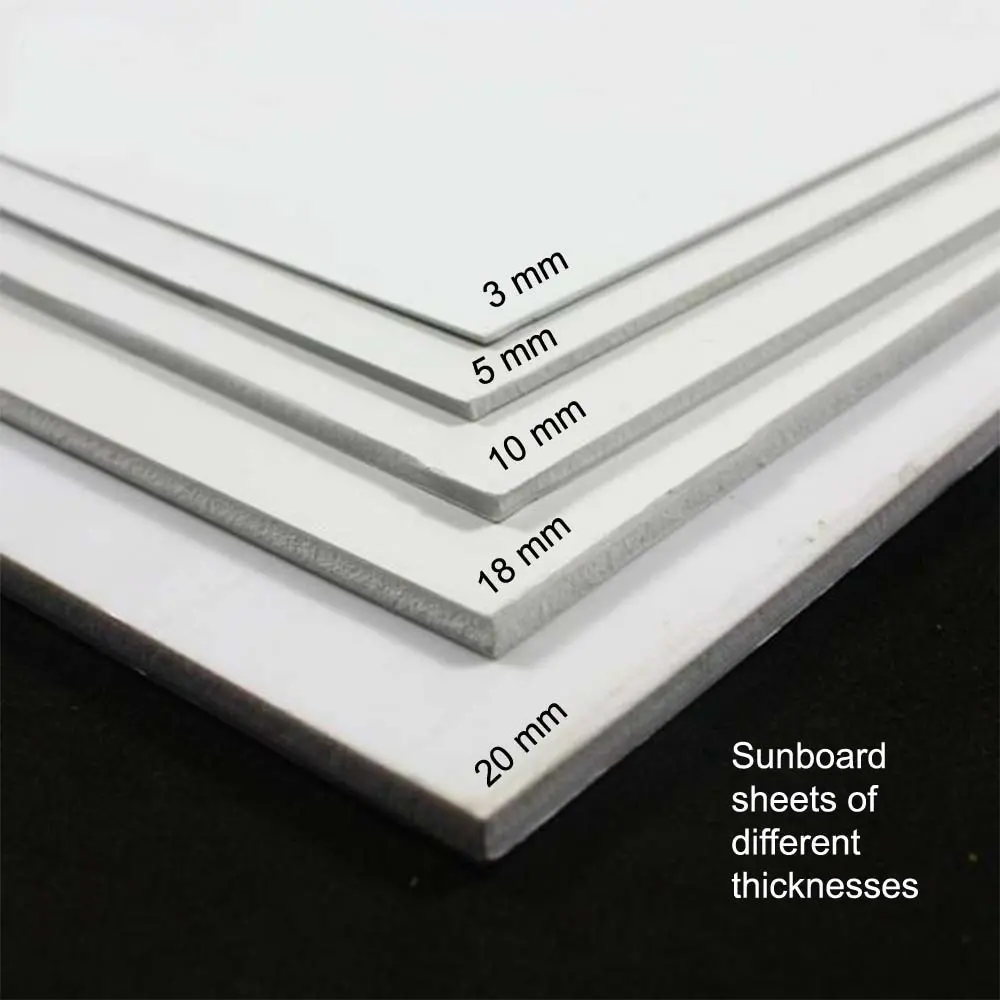

Sunboard sheets are thick. Plastic, as we all know, can also be moulded into very smooth and flat sheets. And manufacturers supply sunboard sheets in a variety of thicknesses ranging from one mm to a full inch.

The print industry regularly uses sheets of 3, 5 mm thickness to manufacture images. But at Orchid Digitals, we can provide prints on sunboard sheets of 10, 15 and even 25 mm consistency.

Foam Board Posters Are Lightweight

A sunboard sheet is exceptionally light in weight. So much so that you can easily carry a sizeable, 8-foot print under your arms.

This low weight is achieved because a large part of the foam sheet is nothing but bubbles of air trapped between loosely packed molecules of plastic. This bubble analogy is probably also why sunboard sheets are colloquially known as foam sheets here in Pune city.

A PVC Sign Board Has Strength & Rigidity

In addition to being lightweight, sunboard prints are also pretty rigid. And when I say ‘rigid’ think wooden, plank-like stiffness. Polystyrene is also a pretty strong material. This is necessary because otherwise, a large-sized print is liable to wilt under its own weight.

Printed Foam Sheets Have A Smooth Surface

Finally, sunboard sheets have a very smooth surface. This enables printers to reproduce high-resolution images on the same. Print houses mainly use the following two methods to create foamsheet prints:

Paste a vinyl sheet on top

Most print-houses print your job on a roll of vinyl. This vinyl print is then pasted on top of a blank sheet of sunboard to create the final product. Printers use a specialised hydraulic pressing machine to fuse the vinyl print and its base foamsheet.

The end result is a very evenly finished, smooth looking job.

Use a flatbed UV printer to print on the foamsheet directly

Some print houses deploy specialised flatbed printing machines. These machines print directly onto the sunboard sheet and cut out the vinyl ‘middleman’.

While this technology cuts one step from the production process, it is still at a nascent stage and has yet to be widely adopted. In case you are curious to learn more, we have a detailed post about UV flatbed printing here.

Applications of Printed Foam Board

A foam board print is a highly versatile marketing solution. Its advertising and communication applications are limited, only by your imagination. Apart from the standard photo posters, sunboard is used for packing furniture, toys, standees, wall prints, exhibition panels, etc.

Here is an exhaustive (but not comprehensive) list of the uses of foam sheet prints that we see on a regular basis.

Wall branding in modern trade stores and retail outlets

Every retail outlet, mall, and shop store advertises its products and offers on posters pasted on the wall. And a foam board poster is the material of choice for this application.

The next time you see a larger than life picture of a model advertising clothes, perfumes, electronics, etc., take a moment to check the material the image is printed on. And you will find that commercial spaces are almost exclusively branded with these low-cost posters to create brand/product awareness.

Since vinyl prints mounted on sunboard have a superb finish and are great to look at, they work beautifully for advertising applications. And since they are highly economical, they also help in keeping your ad budget in control.

Exhibition Panels

An exhibition is one place where prospective clients are continuously judging you and evaluating your products. As such, your marketing communications at trade shows have to up the mark. The posters you use in an exhibition should be able to gain client confidence instantly.

And high-resolution images printed on sunboard are the perfect way to achieve this.

Exhibition stalls are composed of 1-meter broad sections. And our sunboard prints can be easily fixed in these sections using 2-sided tape. Moreover, once the event is over, you can bring back the prints to your office and use them as wall posters.

Sunboard prints are rigid, and carting them to long-distance destinations may prove to be a challenge. So, for those of our clients holding their exhibitions out of Pune, we also have an alternative type of poster material.

This print can be rolled up and carried in a small portable plastic container. Find out more about this solution by visiting this product page on exhibition posters here.

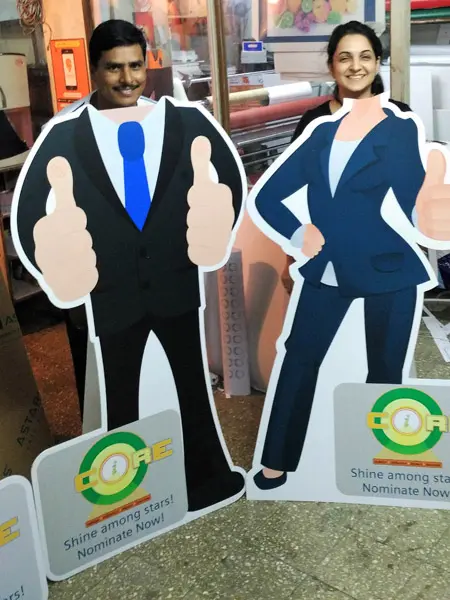

Shape Cut Standees

As I have mentioned earlier, a foam sheet is just loosely fused plastic and has very low density. This makes cutting the print into different shapes very easy.

At Orchid Digitals, we have large-sized laser-cutting and CNC routing machines standing by to process such jobs. These machines can be programmed to cut a rectangular piece of sunboard in just about any shape you can imagine.

And we use this ability to fabricate life-size cutouts.

A cutout standee is a fabulous idea for attracting client attention. We cut sunboard prints in the shape of products, mascots, logos, life-sized models and of course, celebrities. This product is also great for creating selfie booths at parties and events.

For more information on cardboard cutouts, jump to this product page here.

Low-cost stands for point of sale marketing

Foam sheets are pretty rigid. The 5 mm thick variant is almost as stiff as a wooden plank. In addition to this rigidity and strength, sunboard prints also have a very low density.

So, we can very easily cut this material into free-standing, vertical posters.

Sunboard standees are lightweight yet rigid enough to remain erect. They provide an ideal and low-cost advertising solution for supermarkets and other point-of-sale locations.

Fabricating sunboard standees is a relatively quick & easy process. Mass ad campaign managers order hundreds of such stands from us. Most importantly, these standees are also very economical. So, discarding them once the ad campaign ends won’t really hurt your bottom line.

Wall posters for offices and commercial spaces

Pasting a loose sheet of printed paper on a wall looks exceptionally tacky. Alternatively, a flat and smooth sheet of printed sunboard will add a touch of class to your communication.

High-quality posters are the main application of this material. Also, you can create giant-sized posters by printing on sunboard. Two by three feet and 3 X 4 feet are the most standard size prints we process at our end. But a poster of eight and even ten feet is not unheard of, and can easily be provided.

Home interior applications such as personalized furniture panels, paintings and photos

You can use sunboard printing to create some pretty unique furniture concepts.

Here is an example where images of family members are recreated on a wardrobe panel using a foam sheet print. This material is also used in fabricating interesting toys like this wheel of fortune concept here.

Rigid Sunboard Menu Cards

Rigid menu cards are a premium and long-lasting alternative to the traditional paper menus in restaurants. This type of menu is quite popular in fast food and casual dining joints.

A print having some heft is going to look way richer than a regular paper menu. And such a menu will reflect well on the brand/restaurant as well.

A menu card printed on a foam board has a very long life. Since it is made of plastic, there is no question of damage by water. The lamination film on top protects the printed images from oil smudges. Moreover, a sunboard menu will never get dog-eared like the traditional menus printed on paper.

Instagram Frames

As the name suggests, an Instagram frame replicates the popular app’s screen. We print an image with your Instagram username and profile pic. We then cut out the centre portion of the print to make a selfie poster. Handholds are also provided on the back of the frame for the user.

And voila! One Instagram Selfie Booth, ready.

This frame is always a hit at parties and promotional events. Instead of posting your pic in cyberspace, you can physically pose behind the Instagram Window. And to take it one step further, go ahead and post this Instagram frame pic on your Instagram feed. 🙂

Door Hangers & Danglers

Shape-cut stands have a significant form factor and are generally life-sized. But smaller sunboard prints can also be moulded into a variety of shapes for alternative use cases.

One example of a small-sized, non-linear shaped sunboard print is the door hanger used in hotels. We print the ‘Do Not Disturb, and the ‘Clean My Room’ message on the front and back of a foam sheet. The rectangular print is then placed in a CNC machine and cut into the shape of a hanger.

Similarly, danglers for promotional events and custom-printed mouse-pads carrying images of your logo/products are also served up at our outlet here in Pune.

Sunboard Prints are Available in a Variety of Thicknesses

PVC sign boards are manufactured in a vast range of thicknesses.

You can order sheets as thin as 2 mm or as thick as 25 mm. The construction and furniture industry goes a step beyond and works with 40 mm thick PVC sheets. This sheet is a full inch and a half in depth!

You will mainly come across sunboard prints in the print industry having a depth of either 3 mm or 5 mm. While the image reproduction on both these sheets is great, the use case slightly differs for each of them.

3 mm Thick Sunboard Prints

A 3 mm thick sunboard print will look great. But at this thickness (or thinness), the material lacks strength. The poster is slightly loose and will not be able to stand by itself.

I recommend using a 3 mm thick print in scenarios where you can provide additional support to the job. For example, if you are going to drill the poster onto the wall, go ahead and use a 3 mm thick PVC sheet.

But you might want to consider a thicker option for jobs where the print needs more strength.

5 mm Thick Sunboard Prints

Sunboard prints of 5 mm thickness are a more premium variant than their thinner 3 mm counterparts. In addition to looking classy, this material is also very strong.

A 5 mm thick sunboard sheet will not dent easily.

Also, if your application calls for the print to remain erect, you should choose this option. Life-size cutout stands are an example where a 5 mm thick vinyl sunboard is an absolute must.

5 mm sunboard is also mandated for smaller sized prints. For example, if a 3 mm thick, handheld print (like a restaurant menu card) wilts, it will create a bad impression. In this case, using thicker and consequently more rigid material makes sense.

Sunboard Printing on 10 mm Thick Sheets (and higher)

While most of our competitors stop at 5 mm, Orchid Digitals provides prints on even 10 mm thick PVC sheets.

Certain special applications, like an exhibition backdrop for example, calls for prints on a pretty thick base. These prints are large and have to be strong enough not to wilt under their own weight.

For such use cases, we are one of the very few print providers who stock sunboard sheets of 10, 18 and even 25 mm thickness. Do mail us your requirement, and we will revert with a costing for the same.

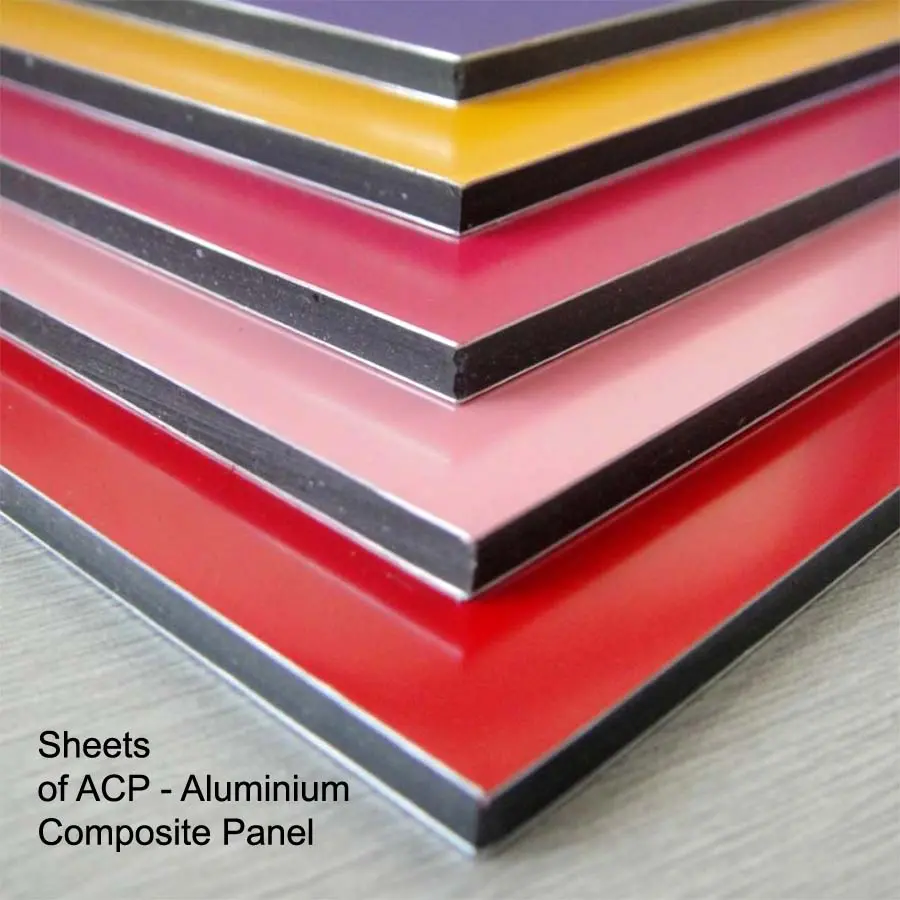

ACP – Aluminum Composite Panel as an Alternative to Sunboard Sheets

Aluminum Composite Panels, also known as ACP sheets, are an extremely strong material used mainly in the construction and furniture industry. ACP panels are also used in the print industry for applications where the print needs to be exceptionally strong.

An ACP sheet is made of two thin aluminium foils with a rubber sheet sandwiched between them. This rubber core is thick, rigid and highly dense. It gives the ACP sheet a lot of strength. And this strength comes in handy when we have to create signs that need to function in incredibly harsh conditions.

At Orchid Digitals, we manufacture road directions signs, safety signs and factory shop-floor prints out of aluminium composite panels. These ACP sheets do not rust or otherwise degrade. With their tough metallic exterior, it is also pretty difficult to dent them.

Printed foam sheets are susceptible to cracks and breakage under strain. But an ACP print will hold its own in even the harshest of environments.

Road signs have to be able to withstand exceptionally severe conditions. And so, we use high-grade cast vinyl prints mounted on aluminium composite sheets to create these signboards.

At Orchid Digitals, we also provide night reflective prints. These prints work exceptionally well in low-light conditions like night-time on the highways or when visibility is reduced in a fog.

How Do You Install A Foam Board Poster?

Sunboard prints are extremely light in weight. So fixing them on walls is pretty easy. Here are some options to install your posters at home or in the office.

Stick the Print Using Two-sided tape

The easiest and most hassle-free method to fix your sunboard print on the wall is to use two-sided tape. You don’t need any special tools or equipment to do the job. You do not even need to buy the tape! Just instruct us, and we will do the needful.

When you commission your foamsheet print from us, we can provide the two-sided tape on its edges for you. Our tape also has very strong adhesion that will prevent the print from falling off.

What remains is for you to peel the tape and paste the print at your end.

Nail the Print to the Wall

Two-sided tape works great for prints up to 2 feet X 3 feet in size. But larger posters are heavier and will require additional support.

For bigger (and heavier) prints, we recommend that you nail the same to the wall. This will ensure that the foam board does not fall off. Since our material is pretty light, thin wire nails will do the trick. You need not deploy large-sized screws, which can otherwise deface the wall.

If you do use big-size screws to fix the print, consider placing a mirror cap on top, to mask the screw head. This will make your installation look very neat and tidy.

Use Stud Caps and Risers

One excellent way of installing sunboard posters is to use risers along with a shiny stud or mirror cap on top.

A riser is a hollow steel cylinder that goes behind the print. Its function is to increase the gap between the sunboard and the wall. In effect, a ‘riser’ raises the print away from the wall to give it a 3D-like effect.

So, you first place a riser beneath the print. You then insert a screw through both, the print on top and the riser beneath. This screw is also drilled into the wall to hold everything in place.

Finally, a stud or mirror cap is placed on top of the screw head to mask it. A stud-cap is a round metallic disk that neatly covers the screw head on the front of the print. The overall effect, once the poster is fixed, looks very premium and classy.

Frame Your Foam Sheet Prints at A Reduced Cost

A lot of our first-time customers come to us with the following intention:

- Get paper or vinyl posters printed at our end

- Frame the above at another frame shop (since we don’t provide framing service)

We offer sunboard with vinyl as an alternative to the traditional wooden frames. I believe that the former is a better and more economical alternative to the latter. A vinyl sunboard print is a complete, standalone product. You can directly drill or paste them onto walls, as described in the previous paragraphs.

These prints will still look great sans any framing.

But some of our customers still prefer to get their prints framed in wood. This is especially the case when the image has to be installed in a home as against an office environment.

So, in this case, I recommend that you only partially frame your sunboard print. This is way more economical than commissioning an entire frame, complete with a glass top and wooden base.

Here is what I mean:

You do not need to spend for the base of the frame

Frame shops will install a base of wood or MDF beneath your loose print to make the same stiff and rigid.

But our 5 mm / 10 mm thick sunboard print already acts as a solid and rigid base. There is no need to purchase an additional wooden base from the frame shop to ‘solidify’ the print. Do away with this base sheet of MDF and save your money.

The glass sheet on top is not required, either

Traditional frames have a protective sheet of glass on top of the print.

But, as I mentioned earlier, at Orchid Digitals, we paste a protective matt/gloss film on top of the printed image. This lamination film makes the poster waterproof and scratch-resistant. You now no longer need the panel of glass provided by the frame shop.

Sunboard printing helps you opt out of both the base beneath and the sheet of glass on top. All you need to spring for is the surrounding frame, or the ‘chaukat’, as we call it in Hindi.

What are the Advantages of using a Printed Foam Sheet?

They Look Terrific!

The surface of a foam sheet print is smooth, coated, and has an even finish. Once a high-resolution vinyl print is pasted onto this sheet, the end result is extremely beautiful and appealing to look at.

These good looks are the reason why vinyl sunboards are so widely adopted by advertising agencies. Almost all the posters you see in supermarkets, malls, and retail stores are made from this material.

Vinyl Sunboard Prints Are Easy to Handle and Lightweight

Foam sheets are incredibly lightweight. Even large sized posters of 10 feet are easy to handle and can be easily carried by just a single person.

This lightweight yet strong material then becomes very versatile and fulfils multiple applications. At Orchid Digitals, we use this material for wall posters, inside acrylic frames, for making display stands, life-size cutouts and even handheld menu cards.

We cover the various applications of sunboard prints in this section here.

Sunboard Prints Are Easy to Install

By virtue of being strong and very light in weight, sunboard prints can be easily installed. You can mount these prints on the wall with just a couple of nails or even two-sided tape.

This convenience for installation makes PVC prints relatively easy to deploy at end-point locations. We talk more about how to install these prints in this section here.

Foam Sheet Prints Are Easy to Maintain

The foam sheet prints produced at Orchid Digitals have a top coat of lamination. Laminated prints have a significantly longer life than their unlaminated counterparts. They are waterproof and scratch-resistant. A layer of lamination film pasted on the image also prevents the inks from fading in the sunlight.

A laminated sunboard print is easy to maintain and keep tidy.

Even if dust settles on this print, it will not be ruined. Just use a damp cloth to wipe away the same, and they become as good as new.

FAQs | Frequently Asked Questions

Sunboard Printing Price

At Orchid Digitals, we provide prints on foam boards of 3 mm and 5 mm thickness. You can also choose to have these prints laminated. Here are the costs for all the options.

PREMIUM

₹130.00/Sq. Foot

Very strong material.

Ideal for long term applications

Example Costing:

₹1560.00 for a print of 4 feet width X 3 feet height*

MIDRANGE

₹100.00/Sq. Foot

Very strong material.

Ideal for long term applications

Example Costing:

₹1200.00 for a print of 4 feet width X 3 feet height*

ECONOMY

₹100.00/Sq. Foot

Very strong material.

Ideal for long term applications

Example Costing:

₹1200.00 for a print of 4 feet width X 3 feet height*

LOW-END

₹80.00/Sq. Foot

Very strong material.

Ideal for long term applications

Example Costing:

₹960.00 for a print of 4 feet width X 3 feet height*

PREMIUM

₹300.00/Sq. Foot

Very thick & strong material.

Ideal for long term applications.

Example Costing:

₹3600.00 for a print of 4 feet width X 3 feet height*

MIDRANGE

₹200.00/Sq. Foot

Strong metallic sheet. Ideal for long term applications.

Example Costing:

₹2400.00 for a print of 4 feet width X 3 feet height*

PREMIUM

₹300.00/Sq. Foot

Extremely robust and strong prints. Will not degrade in outdoor locations and extreme weather. Print mounted on 3mm thick ACP metallic sheet.

Example Costing:

₹3600.00 for a print of 4 feet width X 3 feet height*

MIDRANGE

₹240.00/Sq. Foot

Extremely robust and strong prints. Will not degrade in outdoor locations and extreme weather. Print mounted on 5mm thick sunboard sheet.

Example Costing:

₹2880.00 for a print of 4 feet width X 3 feet height*

ECONOMY

₹200.00/Sq. Foot

Extremely robust and strong prints. Will not degrade in outdoor locations and extreme weather. Print in a roll form with sticker back.

Example Costing:

₹2400.00 for a print of 4 feet width X 3 feet height*

Metallic

₹200.00/Sq. Foot

Print on silver metallic foil with matt / gloss finish. Ideal for interiors.

Example Costing:

₹ 2400.00 for a print of 4 feet width X 3 feet height*

Textured

₹200.00/Sq. Foot

Print on textured vinyl. Ideal for interiors.

Example Costing:

₹ 2400.00 for a print of 4 feet width X 3 feet height*

Sparkle/Glitter

₹240.00/Sq. Foot

Print on silver metallic foil with sparkle / glitter top coat. Ideal for interiors.

Example Costing:

₹2880.00 for a print of 4 feet width X 3 feet height*

* Please Note:

- The rates quoted above attract 18% GST.

- The rates mentioned above are per square foot.

This means you first need to work out the total area of your job to arrive at the final cost.

For example, let us assume that you require two sunboard prints of 3 mm thickness, without lamination. Further, these prints have a width of 3 feet and a height of 2 feet. In this case, the total cost of the job is calculated as follows…

3 feet width X 2 feet height X 2 copies X Rs.80.00 (cost of print, as per the table above)

= Rs.960.00 + 18% GST

Shipping and Delivery

- Sunboard prints can be delivered anywhere in Pune City and its nearby areas. We also ship bulk quantities for longer distances.

- Delivery charges are extra and will be communicated to you once we receive the delivery address.

Question: Does this product get shipped out of Pune City?

Answer: We do not ship small quantities of this product outstation. Apologies.

Here are a couple of reasons for the same:

- Hassle and Risk in Transportation: Sunboard is liable to break in transit. Also, these structures are pretty large and bulky. We need to hire a tempo to deliver them.

- Economic Feasibility of Transportation: These boards are a pretty low-cost product. So, packing and shipping them over long distances means that our customers will pay more for the cost of delivery than the actual print cost.

Therefore, if you are stationed out of Pune and need just a few images, it makes sense for you to source the print from your local printer. All you have to do is share/take a print of the above post, show your local printer the material specifications and commission a similar job from him.

For larger quantities, do not hesitate to get in touch with us.

Get a Quote for Customized Sunboard Prints

Please leave us your details and we will respond promptly

Similar Products

Original cotton canvas prints to create classy photo frames. Jaw-dropping…

Acrylic Sandwich Frames for Displays at Retail Stores and Offices…