Types of Wide Format Inkjet Printers & the Inks They Use

What is Wide Format Inkjet Printing?

What are the Types of Inks Used in Commercial Inkjet Presses?

A Must Read to Gain In-Depth Knowledge of Commercial Inkjet Printing.

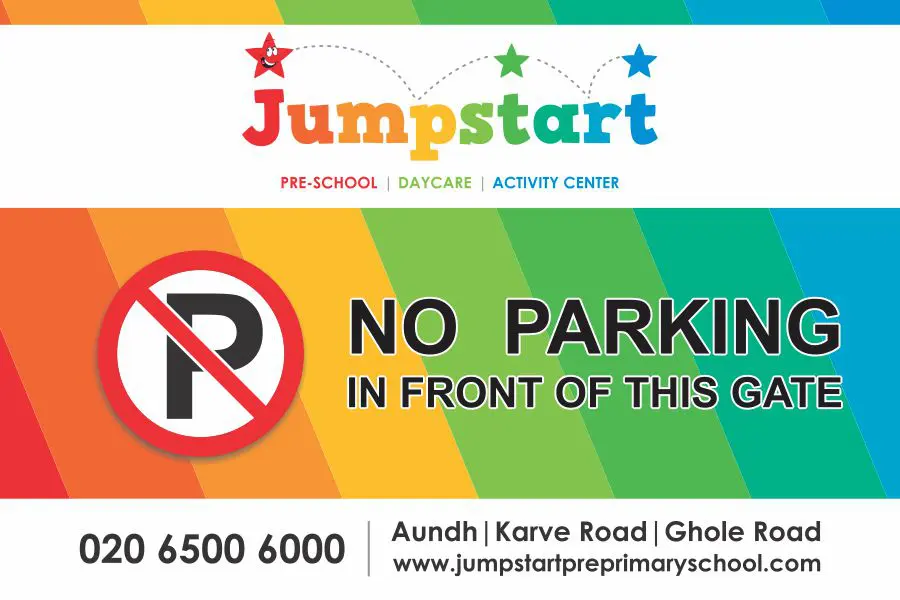

We are all used to seeing huge 100 feet (and even larger) hoardings, erected at prominent street crossings in the city. Or perhaps the high-quality photo print of a larger than life model, pasted inside a high-end clothing store, may have caught your eye.

But have you ever wondered how these humongous prints get manufactured?

Maybe you recall the last time you drove down the highway in the evening or at night. You would have surely noticed those huge direction signs reflecting the light beam of your car headlights.

For all the examples mentioned above, there are two common denominators…

- The size of the prints are very large

- All these jobs have been printed on inkjet printing machines

But this does not mean these large scale printers cannot reproduce small sized jobs.

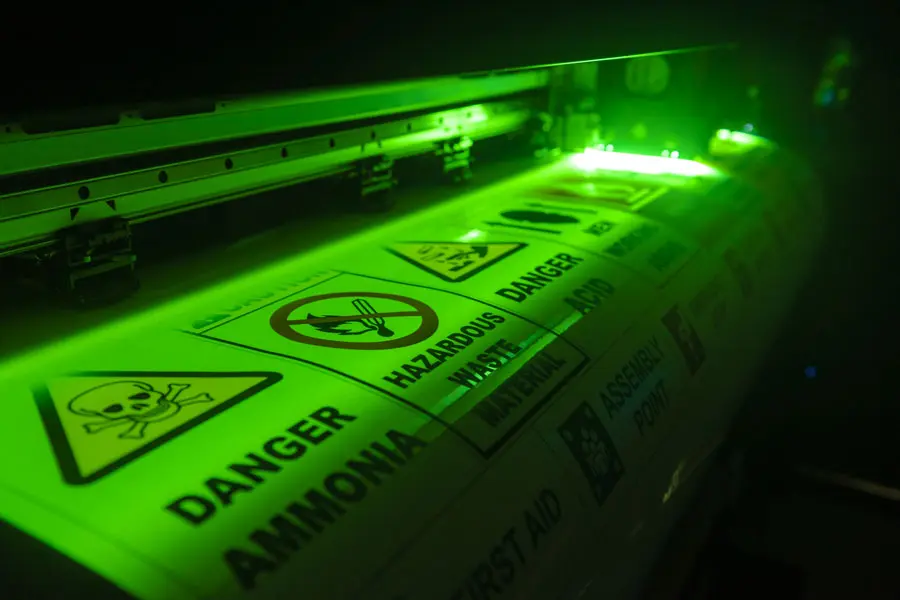

Inkjet-printed products both big and small have become ubiquitous in our everyday life. Be it personalized T-shirts bearing our name and team colors, a skin for our laptops, or safety signs that glow at night in office complexes, printing is a constant in our everyday life.

An entire industry is built around wide format printing services. This market place is made of print shop providers, print service bureaus, designers, printer manufacturing factories, media suppliers, ancillary suppliers like inks and spares, print magazines, trade shows, etc.

Wide-format printing is big business. The turnover of the wide-format industry is conservatively expected to grow to 10.6 billion dollars by the year 2023 according to this study.

And this is because wide-format inkjet prints find applications in a variety of sectors. These machines are used in construction, sign making, furniture, architecture, textiles, home and office design, marketing, and advertising, to name a few.

How Will You Benefit From Reading This Post on Inkjet Printers?

To the casual observer, the technology, trade lingo, market applications for inkjet prints, etc. might all seem daunting. But seeing that you are here, I am guessing that you are probably one of the following…

- You are an entrepreneur or budding print shop owner who wants to invest in a production-level inkjet printer and is looking for detailed knowledge about the same.

- Perhaps you are a market analyst or student researching in-depth knowledge about wide format printers and their end applications

- Or maybe you are an end-user in need of print services who wishes to know more about inkjet printing before making a purchase decision.

Keeping the above readers in mind, I have crafted this post to help simplify the subject of wide format inkjet printing. Reading it will help you answer the following questions:

- What are wide-format inkjet printing machines?

- What are the applications of wide-format inkjet printers?

- How do inkjet printers actually work?

- What are the different types of commercial inkjet printing machines used by print houses, based on the types of inks they use?

- What are the different types of ink systems used by commercial inkjet printers?

- What are the strengths (and shortcomings) of the above-mentioned inks?

Why the Name ‘Wide Format’ for Industrial Inkjet Printing Machines?

Inkjet printing machines in the digital printing industry are also referred to as ‘wide format printers’ or ‘roll to roll’ printing machines.

The adjective ‘wide-format’ is derived from the fact that these machines have a pretty wide footprint. The print bed allows for printing rolls as wide as 10 feet / 3.2 meters. A 10-foot printer can print upon rolls having smaller widths of 2, 3, and 5 feet. But the maximum size of a roll that it can accommodate is 10 feet in width.

In answer to the first question posed in this post, a 100-foot wide hoarding is not printed seamlessly in one go. What we do is print 10 individual tiles of 10 feet each. These tiles are then joined together to create a large-sized print. Tile printing theoretically allows us to print jobs of infinite widths.

What is the difference between ‘Large-format’ and ‘Wide-format’ Inkjet Printing Machines?

In the print industry, we also have another category called ‘large format’ inkjet printers. Of a slightly smaller size, large-format inkjets fall somewhere between the A4 sized home desktop inkjets and the industrial-grade wide format printers.

These printers accommodate media widths from 18 inches up to 3 feet / 0.9 meters. Print-for-pay shops invest in the bigger wide-format machines to cater to the needs of different clients. Large format printers on the other hand are mostly found in businesses and offices which need large-sized prints for their own consumption.

For example, an architectural firm does not resell prints but frequently needs large A2 or A1 sized outputs of CAD drawings and design layouts.

In either case, commercial inkjet printers are able to print jobs at sizes significantly larger than our office desktop machines.

Why are ‘Wide-format Printers also referred to as Roll-to-roll printers?

Industrial wide-format printing machines do not print on individual sheets of paper. Rather, they process large reels of paper, flex, or vinyl media. You can think of this media as similar to rolls of cloth found in tailor shops and clothing stores.

These rolls are mounted on an unwinder mechanism set behind the machine. The media is then unspooled onto the print bed where ink heads fire ink upon it. The printed media rolls out of the print bed and then gets rewound or packed on to another roll called the rewinder.

Hence the adjective – ‘Roll-to-Roll Printing Machine’ is also apt for wide-format inkjets.

With your question ‘what are wide-format commercial inkjet printers?’ answered, let’s dive into the applications of the same.

What Are the Applications of Commercial Wide Format Inkjet Printers?

A print shop uses wide format printing machines to print on a variety of media. And depending on the media being processed, we can cater to applications in different industries. Here is a table to illustrate the same:

| Industries that a print shop can cater to, using wide format inkjet printers | Print media used for the job | End application of the prints |

|---|---|---|

| Promotion, marketing, and advertising | Flex printing | Hoardings, banners, backlit and frontlit shop boards |

| Vinyl printing | Banners, posters, stickers | |

| Construction and architecture | Paper prints | CAD drawings, architectural designs, and plans |

| Home and office interior design | Glass Films | Prints for home/office glass partitions and windows |

| Wall Vinyls | Wallpaper prints with custom designs on walls | |

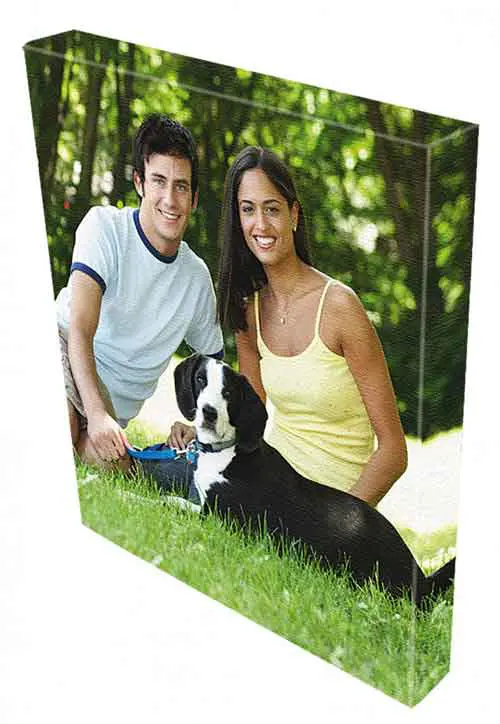

| Canvas rolls | Photo reproduction, fine art reproduction, museum prints | |

| Retail (Point-of-Sale) | Sunboard sheets | Product posters, wall posters, display standees, rigid menu boards |

| Photographic sheets | Product posters, wall posters, display standees, rigid menu boards | |

| Backlit and translite films | Clip-on LED panels & light boxes | |

| Education and corporate offices | Poster rolls | Posters for presentation, office frames, charts |

| Garments and textile industry | Printing on cloth | Flags, banners, wearable garments |

| Electronics | Polycarbonate sheets | Control panels, calibration sheets |

| Automotives | Vehicle films | Decals, logos, vehicle wraps |

| Label industry | Sticker media with different adhesion properties | Price labels, product labels, logo stickers, removable glue stickers, permanent stickers, etc. |

| Corporate gifts | Magnetic sheets | Fridge magnets |

| Heat transfer media | Mousepads, T-shirts, cups, mugs, caps, etc | |

| Photo films | Picture frames | |

| Trade shows and exhibition industry | White/grey back photo posters | Standees and portable display solutions |

| Flex prints | Stage Backdrops | |

| Vinyl prints | Canopies, tents, and promo tables | |

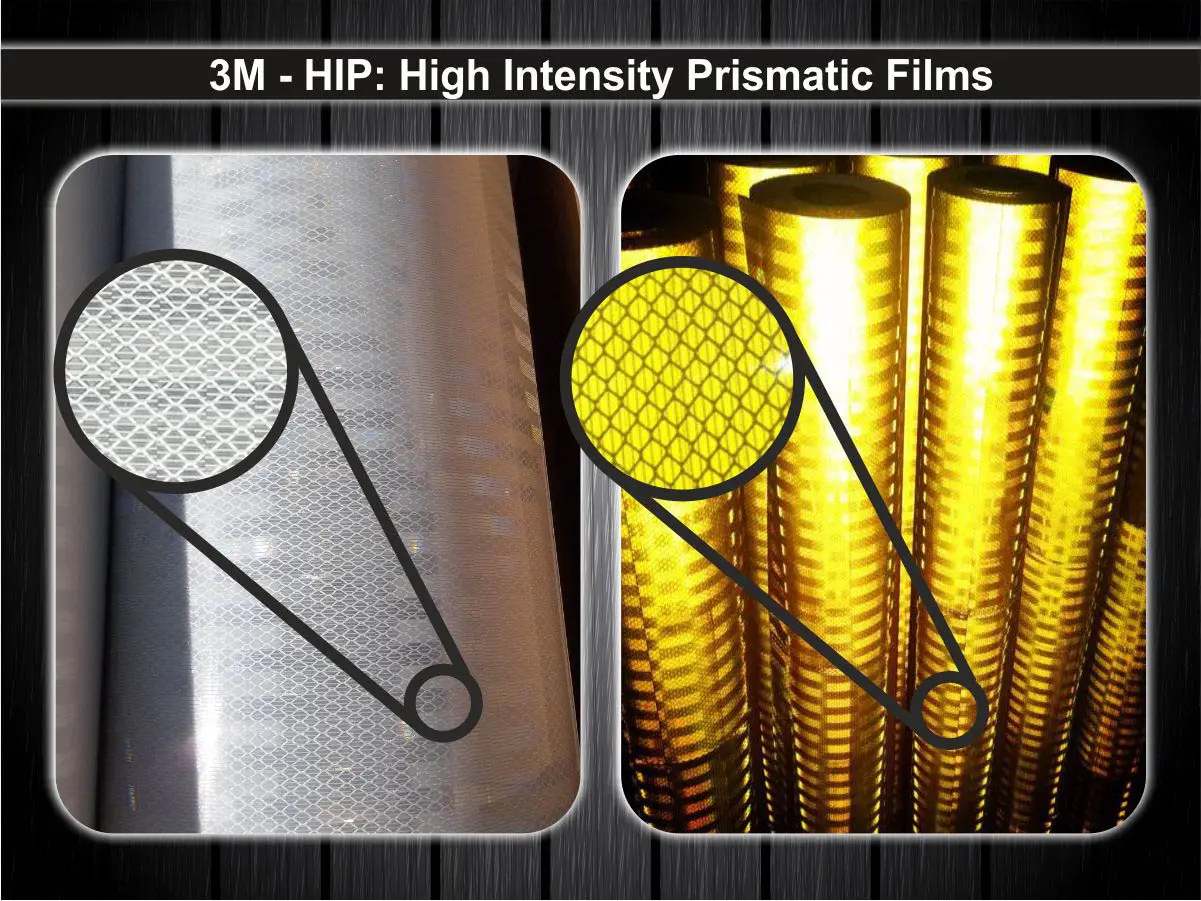

| Specialty applications | Reflective media | Road signs, direction boards |

| Nightglow media | Safety signs for dark locations | |

| Metal foils | Interior decoration prints |

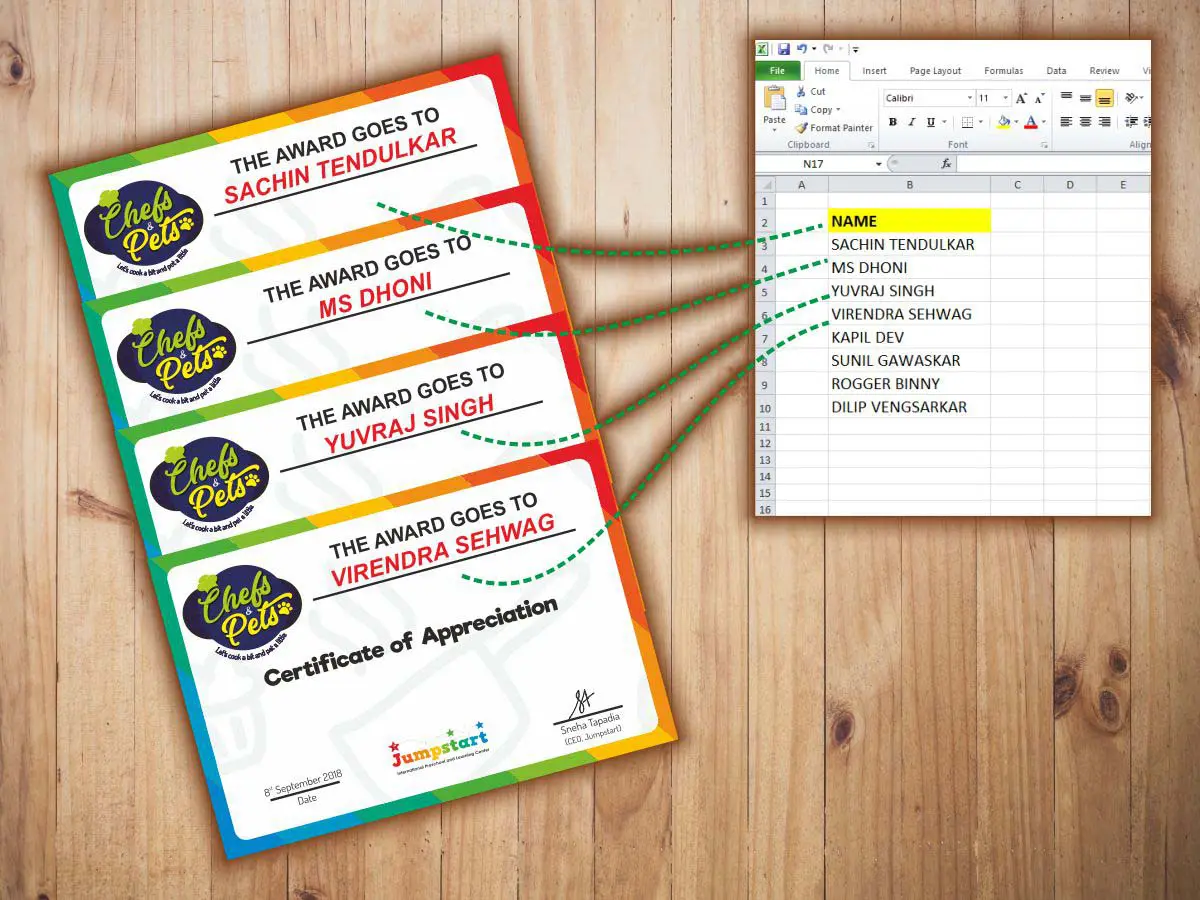

The point I am trying to make with the above table is that the same wide format printing machine can be loaded with different kinds of media. And prints on a variety of media increases the market reach of the print provider.

What Types of Inkjet Printers Are Available in the Market Today?

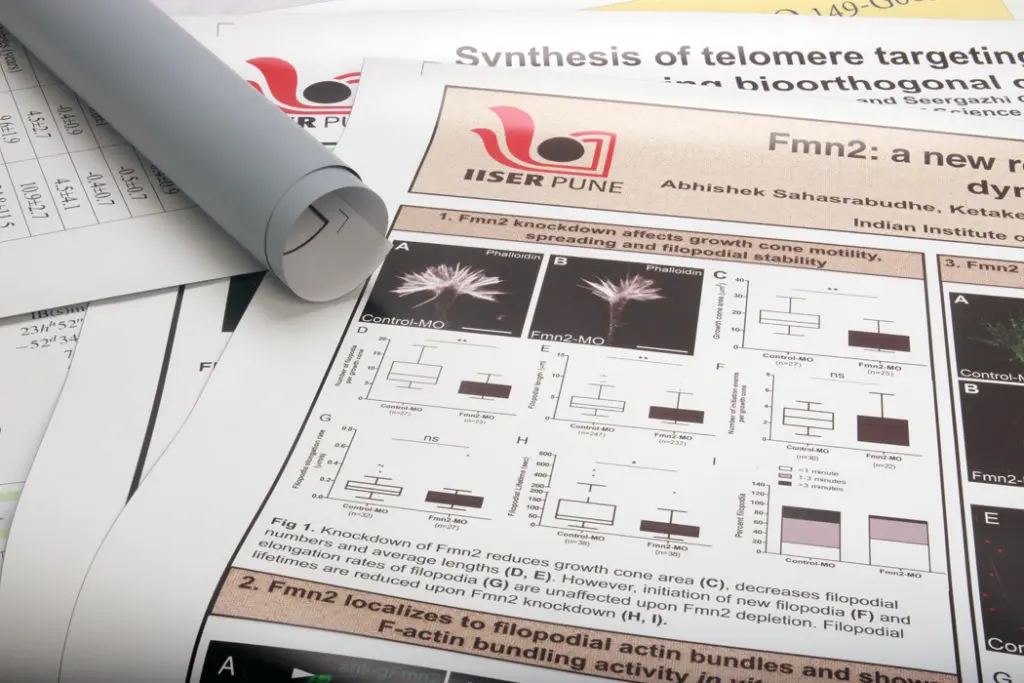

The underlying principles for the working of all inkjets are largely the same. Our home printers as well as the large format and industrial wide format machines are all equipped with ink heads. These ink heads are mounted on a rail-like bar called the carriage.

The ink heads move laterally on the carriage while firing ink on the print media beneath. This is exactly similar to the office inkjet, we have all seen in action.

But while the working mechanism of both desktop and production printers is more or less the same, industrial printers have different types of print heads. And these print heads are designed to work with different ink technologies.

For example, SOHO printers and entry-level large format printers use water-based inks while UV inks are the new kids on the block where industrial printing is concerned.

Broadly speaking, there are 5 main types of inks/printers used by commercial print shops.

- Solvent ink printers

- Eco-solvent printers

- Aqueous ink printers

- Latex printers

- UV or ultraviolet ink printers

While all the machines listed above can print on a wide variety of media like vinyl, flex, paper, cloth, etc. each ink technology has its own strengths and advantages.

For example, prints on hard solvent machines are pretty economical and ideal for jobs like large hoardings. But there is a limit to the resolutions they provide. Eco-solvent and aqueous ink printers, on the other hand, are able to reproduce very high-resolution images at a stunning quality. But, this advantage comes at a marginally higher price.

Latex and UV printers are also known for their ability to provide very high-quality prints. Additionally, these printers do not require and specialized material to print upon. They can reproduce images on just about any kind of media be it paper, uncoated plastic, cloth, and even rolls of leather.

We will discuss the differences in inkjet technologies in-depth in the ‘Inks’ section further below. For now, let me just state that the differences in the capabilities of different types of wide-format inkjet printers mainly stem from the different ink technologies these printers deploy.

And to fully understand these differences we need to first take a brief detour and understand how inkjet printing actually works.

How Do Inkjet Printers Work?

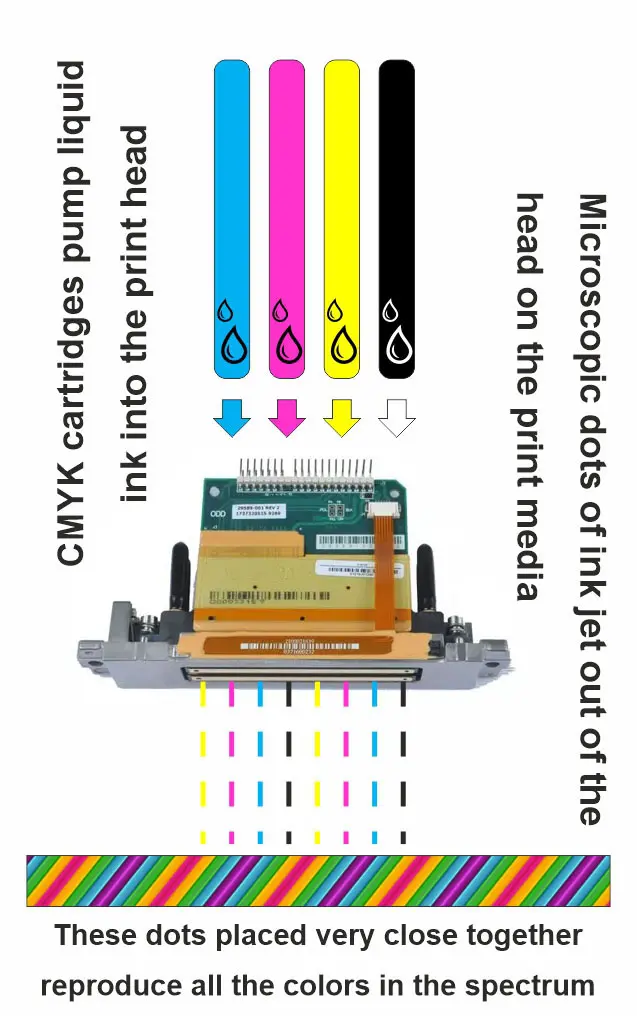

As I mentioned above, inkjet printers are fitted with ink heads. Most printers generally have four heads, each containing four primary colours, namely – CMYK (Cyan Magenta Yellow Black). And a combination of these four colours can create virtually any shade in the colour spectrum.

Colour theory in itself is a vast subject which falls beyond the scope of this discussion. Suffice it to say, that at the time of printing, these four colors are mixed like the paints on an artist’s palette to create new colors and tints.

And when mixed in different proportions, a combination of CMYK can faithfully reproduce all the required shades needed to reproduce the images in our prints.

Each of the above mentioned four inks essentially have two components – a pigment and a carrier.

The pigment obviously is the component that lends the colour to our print. The carrier, as the name suggests, is the liquid that carries the pigment from the ink head onto the media.

For example – If red dye is suspended in a solution of water, the water becomes the carrier in this case. The solution is then sprayed out by the inkhead onto the print media.

The water component of the ink evaporates and leaves the residual red dye onto the media. This example also illustrates why inkjet prints are always a little wet when fresh off the press.

Now, ink heads have microscopic nozzles or jets through which the ink gets sprayed out. Think of each inkjet as the ‘holi / rang panchami’ pichkari squeezing out colored water at high pressure.

Thousands of such jets or nozzles are fitted into a single ink head.

Our ink heads move laterally over the print media. And they spit out microscopic dots of inks at a high speed. A close analogy of this would be a paintbrush depositing colors as it moves over a sheet of canvas.

The only difference is, while the brush actually touches the canvas, an inkjet head glides a few millimeters above the vinyl media.

Carrier and Colorants – The Two Main Components of Inkjet Inks

Coming back to our discussion on ink printing technology, here is what actually happens in the printing machine:

1. We have liquid ink of different colors, filled in the ink heads.

2. This ink then gets squeezed out of microscopic-sized holes or nozzles of the print head and falls on the print media/roll running through our machine.

3. Remember, the liquid ink is primarily made of two components:

- The carrier, which is made of water or a solvent solution

- The actual colors in the form of dyes/pigments that are suspended in the above carrier.

4. Once the liquid ink is deposited onto the vinyl (or other printable media), it has to quickly dry up. This happens either naturally or with the aid of artificial heaters.

• At this stage the carrier component of the ink (the water or solvent carrier in which the colors are suspended), evaporates.

• What gets left behind are the residual colors that go into the making of our photographic image.

Walk close to any solvent inkjet in action and you will get a nail polish like smell. What you are actually smelling are hydrocarbons being released in the air. This is because the solvents in the ink (which have been fired onto the media) start drying.

As I have mentioned above, the physical working of all inkjet printers are the same. The humble desktop printer in your office and the huge 10 feet wide format printers at my print shop have at their heart an ink head gliding over printable media, spraying out ink as they do so.

What changes are the types of inks being deployed by these machines. So we’ll also have a look at the ink technologies mainly dominant in the print industry today, further below.

But to understand printing inks and their capabilities, we first need to understand what ‘print resolution’ is all about.

A Brief on Printer Resolutions

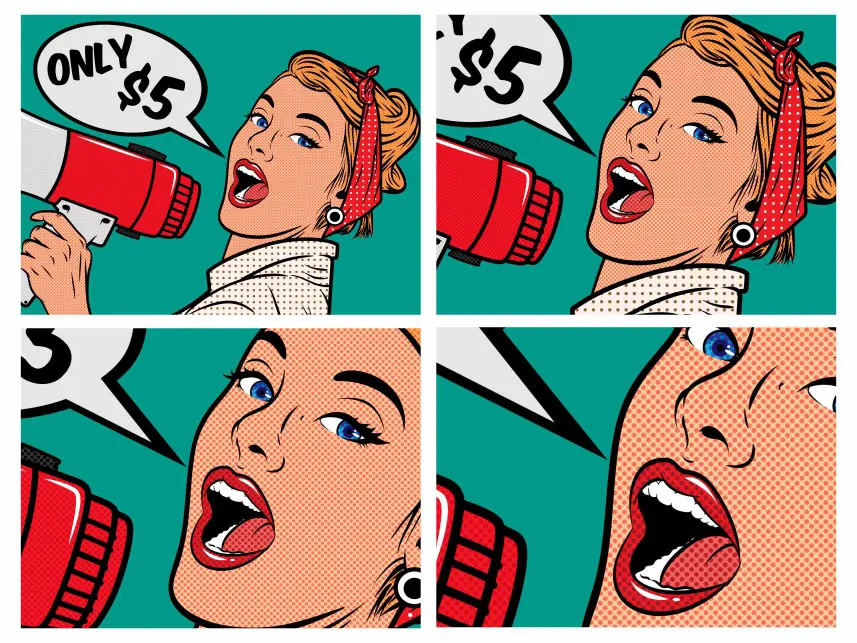

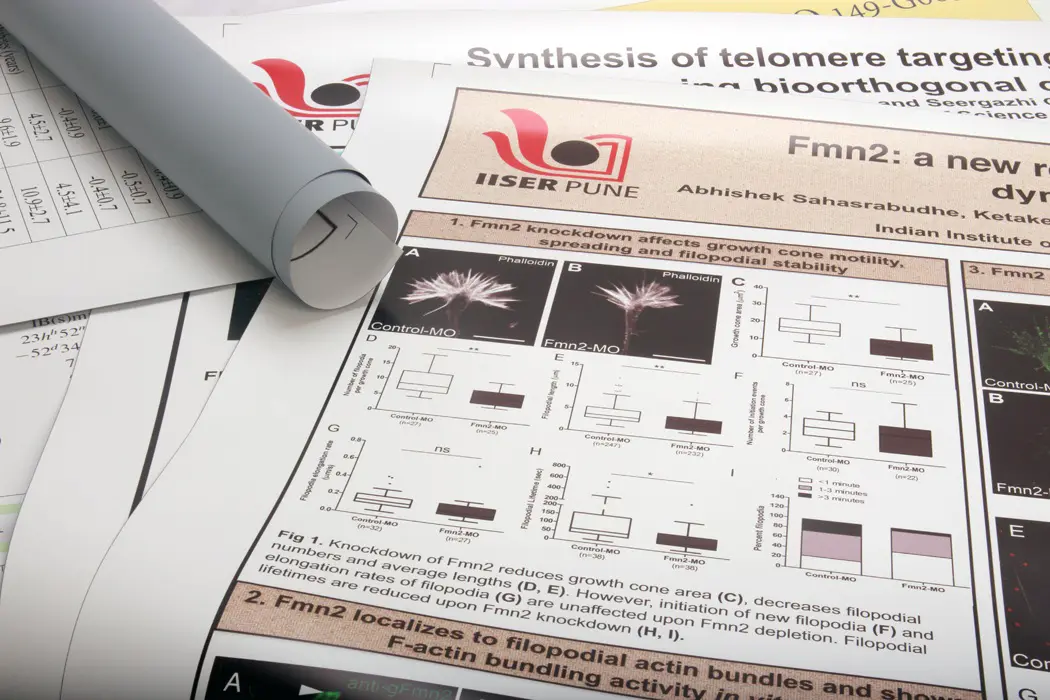

Inkjet printers reproduce images by printing hundreds of small dots closely placed together. These dots are microscopic and in most cases, cannot be individually made out by the human eye.

We can only discern the overall image created by all the dots packed tightly together.

Low-resolution newspaper prints are an exception to the above statement. Look closely at the images on the front page of today’s edition and you will be able to discern a matrix of fine dots in the print.

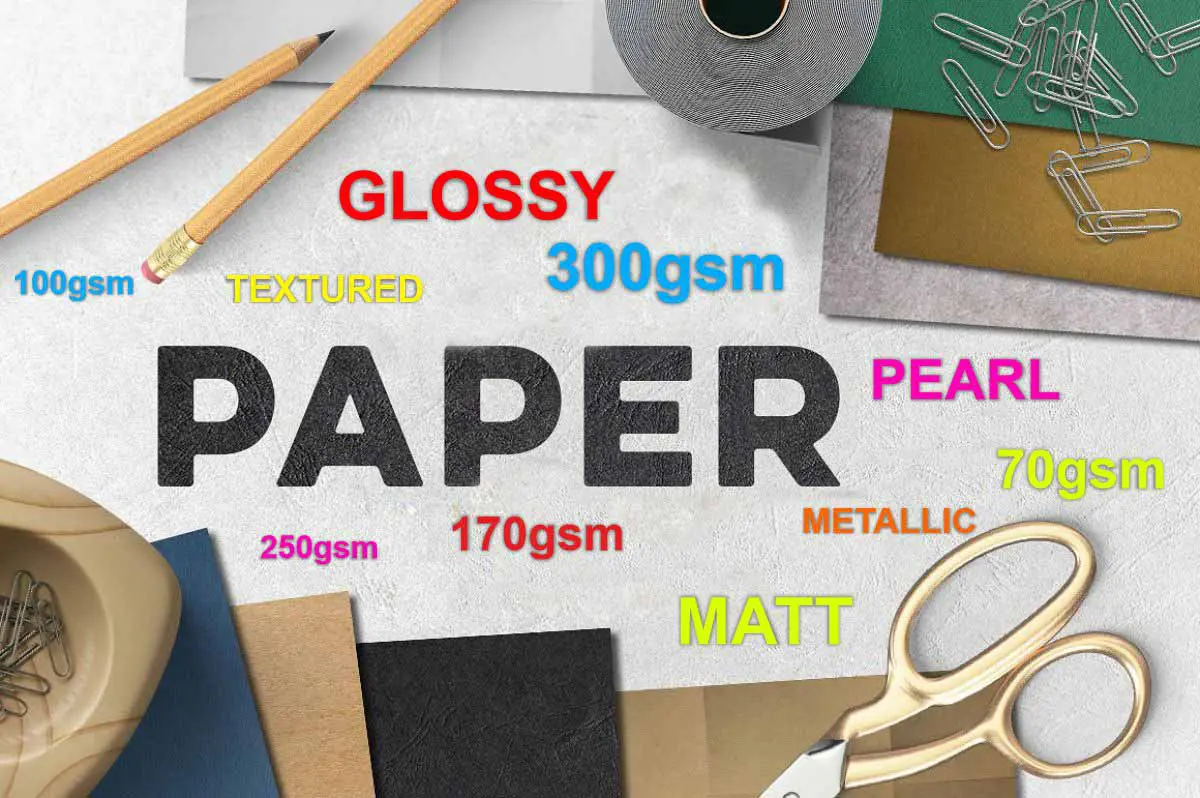

So obviously, the resolution of an image is determined by the number of dots that go into its making. The closer the dots, the finer the image.

Newspaper images are typically very grainy. Images in a high-end fashion magazine are much more superior. The difference is that rough newsprint paper can only be imprinted with large ink dots. Whereas, the glossy coated paper of a magazine can accommodate finer and closely spaced ink dots.

On a high-resolution photograph, the dots are so close that it would require a jeweler’s eyepiece or even a microscope to make them out individually.

A printer’s capability to reproduce high-resolution images is determined by how small an ink dot it can generate. High-resolution inkjet printers typically create ink dots measuring 20 picolitres or less. And to generate such microscopic dots of ink, we need two things –

- An inkjet head having nozzles of microscopic diameters.

- An ink carrier thin enough to be squeezed through the above nozzle.

Obviously, the tinier the nozzle, the finer our jet of ink. And the finer our ink spray, the smaller the resultant dot.

This means that print heads capable of reproducing the smallest dots are also the ones that can deliver the highest quality in terms of image resolutions.

This statement is important and has implications for both the print service provider and an end customer looking to get a print job done.

If you are looking to set up a print shop, the choice of your first machine should depend on its resolutions and capability to produce high-quality output. If on the other hand, you are an end-user, you need to be clear about the end application of your job.

For example, a short-lived, single-use, event banner can probably be printed at an economical price on a low-cost solvent printer at low resolutions. On the other hand, a high-quality, family photo frame will be displayed in the house for years together.

So for this job, go for the high-resolution print generated on an eco-solvent or latex printer. Also, opt for a premium media like canvas, to print the job on.

What Kinds of Inks Are Used in Wide Format Inkjet Printers – a Better Understanding of Their Different Types

The use of different inks helps printers process jobs for different applications in the branding of commercial, interior, and exterior places.

Now that we are armed with a better understanding of how inkjets actually work, we’ll delve deeper into the types of inks used.

This section describes the merits and shortcomings of different ink chemistries. It will help you decide which technology works best for your printing job.

1. Aqueous Ink Printers

All first-generation inkjet printers worked with aqueous inks. This technology is widely used in entry-level printers. Also, virtually every desktop printer uses aqueous ink technology.

As the name suggests, this ink has water as its carrier. The other part of the ink, that is the colorant can either be:

- Dyes, or

- Pigments

Difference between dye inks and pigment inks in inkjet printers

Dyes are liquid colorants that dissolve completely in water. Pigments on the other hand are solid particles of colorants that stay suspended in water.

Think of pigment inks as a water solution saturated with microscopic particles of colored chalk. These particles are not dissolved in the water but stay suspended in the same.

Aqueous ink chemistry is pretty simple. These inks are also pretty cheap and easy to manufacture. This is perhaps why there are so many home-grown manufacturers who provide bulk feeding ink systems as a significantly lower cost alternative to original ink supplies.

Moreover, dye inks are very vibrant and the color output of these printers has a significant punch. These properties make dye-based aqueous ink printers ideal for reproducing high-resolution photos and images at a very low cost.

The problem with dye inks is that they are completely water-soluble. And obviously, water-based solutions are going to be susceptible to rain and sunlight. This means that even if a single drop of water, falls on the print, it gets completely ruined.

Laminating aqueous ink prints for water protection is mandatory. The inks also fade pretty quickly when exposed to sunlight or when they are installed in an outdoor environment.

Pigment-based inks are slightly more robust than their dye counterparts. They do have some water resistance. But they are not completely waterproof like solvent or eco-solvent inks.

Also, unfortunately, the enhanced strength of pigment inks comes at a cost. Their color gamut is smaller than dye inks.

Color gamut means the number of colors that a particular set of inks can faithfully reproduce. For example, if there are infinite shades of red, pigments can reproduce a significantly lower number of reds than dyes.

Because of this shortcoming, pigment ink prints could never achieve the vibrancy of dye inks.

Aqueous inks (both dye and pigments) have one thing going for them. They are very economical. This point is important because printing inks account for a significant cost component in every print service provider’s business operations.

Aqueous Ink Prints are Not Very Robust

Aqueous ink prints are not very strong in the sense that they get easily ruined by scratches and slight mishandling. Also, they are not waterproof. Further, these inks fade in sunlight.

All these factors make water-based inkjet prints unsuitable for outdoor applications.

One other problem is that aqueous ink printers can only print high-resolution images on specially coated media. Water seeps into uncoated media like paper.

Try printing a photo on your office inkjet and you will see that the lines of the image get blurred. This is because water-based inks spread and blot on plain uncoated paper.

To achieve prints of good print quality, we have to use media that is compatible with water-based inks. So the use of aqueous inkjet machines, with respect to printable media, gets severely restricted.

Also, as I mentioned above, water-based inkjet prints need to be specially laminated with a clear film of plastic. This lamination acts as a protective layer and the prints are able to withstand scratches and the rigors of everyday wear and tear.

It will also protect the prints from water to a limited extent. But, lamination adds an additional step to the production process. And this step increases both time and costs for completing the job.

To conclude, aqueous ink printers are from an older generation and are being phased out in the print industry. With the advent of very high resolution and robust eco-solvent inkjets, aqueous ink technology is quickly on its way out.

2. Solvent Ink Prints

Solvent-based inks are pretty robust and ideally suited for outdoor applications like hoardings and shop boards. These inks are strong enough to withstand the elements, such as rain and sunlight.

On the other hand, solvent printers generally output low-resolution prints and also exude a typical hydrocarbon smell. And these low-res prints are generally not used for indoor applications which require a more premium print quality.

Solvent flex printing machines have a comparatively large drop size. The print heads on solvent machines spray ink drops of size 40 – 60 picoliters.

While the larger drop size does result in slightly grainy image reproduction, it doesn’t really matter. This is because solvent prints are typically used for outdoor applications.

If you are going to view a hoarding which is 40 feet distant from your car, waiting at the traffic signal, you won’t even notice the low resolution.

The biggest advantage of solvent printing is its low print cost. When you need to run a large campaign involving hoardings across the city, solvent inkjet printing is your best bet.

On the flip side, solvent-based inks are typically non-biodegradable. Also, there are studies that claim that prolonged exposure to them can be harmful to humans.

3. Eco-solvent Vinyl Prints

Most print houses will have eco-solvent printers installed at their premises. Machines based on this technology, can output very high resolution prints. These prints are suited for indoor applications where the viewer is going to see the images up close.

Eco-solvent printing machines have a number of advantages in their favor –

- Eco-solvent printers have very high resolutions. These machines are known for their ability to generate photo-quality output at stunning image resolutions.

- Eco-solvent inks are weather-proof. A print service provider need not laminate his prints to protect against rain and sunlight. Elimination of this step in production leads to considerable savings in both, time and money.

- Perhaps the biggest advantage in favor of eco-solvent printing machines is the fact that they have an extremely low run cost. The low cost of inks and machine maintenance helps make the business very competitive.

Eco-solvent printers have been accepted across the entire print industry. And this is because…

All media manufacturers ensure that their media are compatible with eco-solvent inks. So owners of eco-sol printing machines are absolutely spoilt for choice when it comes to media selection.

In addition to the standard media like flex and vinyl, owners of eco-solvent printers can output jobs on paper, cloth, mesh films, backlit films, canvas, tarpaulin, metal foils, radium reflective films, night glow films, glass films, and even rolls of artificial leather/rexine.

With a wide adaptation of this technology, there is no dearth of suppliers for spares and inks. There is also a plentiful availability of trained engineers, should your machine ever break down or need maintenance.

Almost all commercial communication in malls, retail stores, and office environments, bearing high-resolution images and fine text, are currently being printed on eco-solvent machines.

4. Latex Ink Printers

HP Latex inks are a proprietary technology developed by HP (Hewlett and Packard). The company positions latex inks as an eco-friendly alternative to solvent-based inkjet printers.

Like aqueous ink formulations, these inks also have water as their carrier component. But in place of dyes or pigments, the colorant is made of microscopic particles of plastic or as the company calls it, ‘latex’.

Latex printers come equipped with heaters that reach a very high temperature. These heaters dry up the water component of the carrier almost instantaneously.

Also, the high heat melts the latex / plastic particles and fuses it with the print substrate. Since the microscopic dots of polymer can be melted onto just about any surface, the range of media that can be used with a latex printing machine is pretty wide. HP claims that latex inks can print on thin uncoated paper as well.

Latex printers and HP printers, in general, are known for their vibrant colors and very high-resolution prints. Many print houses swear by their image quality.

However, HP Latex inks are expensive. Also, you can only buy them from HP as there are no third-party alternatives for the same. This is because latex inks are a complex formulation and cannot be easily reversed engineered. We discuss bulk ink feeders in more detail here.

Also, some critics have pointed out that the very high temperature needed for melting the granules in latex inks lead to the following disadvantages:

• More heat means more power consumption and consequently higher run cost

• Not all media are compatible with high temperatures. Thin paper and plastic films especially, warp or melt when exposed to this environment.

• Since the machine heater has to achieve a particular temperature before printing can begin, there is a significant wait-time before each job. More so when different media need to be loaded onto the machine. This reduces efficiency, especially when print jobs have to be processed on different media.

Every new technology takes time to evolve and HP has been continuously upgrading its latex printer line of models. The company representatives and machine resellers say that a lot of the shortcomings mentioned above have been addressed.

5. UV or Ultraviolet Inkjet Printers

Ultraviolet inkjet printers (commonly referred to as UV ink printers) are a fast emerging alternative to eco solvents. In these printers, the ink that gets deposited on the media does not ‘dry’ in the traditional sense of the word. Rather, the UV ink is cured by UV lamps placed next to the ink heads.

Ultraviolet inks are photo-reactive. This means that the inks undergo a chemical reaction and transform in the presence of certain wavelengths of light.

As the ink head deposits UV inks on the substrate, a UV lamp placed on the machine quickly cures the same. The inks ‘dry’ and in fact become rock hard, the moment they fall on the print media. This is another reason why the process is referred to as ‘LED UV printing’.

I use the word ‘dry’ in quotes because there is no actual drying taking place here. Unlike aqueous, latex, and solvent printers, UV inks do not contain any carriers like water or solvents which need to evaporate.

Ultraviolet Inkjet Printers are capable of achieving extremely high resolutions as well.

Some features of UV ink systems are:

UV Inks Are Extremely Strong

They are scratch and scuff resistant. If you need vinyl prints for exceptionally harsh environments, you would do well to opt for this technology.

Also, UV inks are highly resistant to rain and sunlight. So UV ink prints need not be laminated for additional protection. By eliminating this step in the production process, print houses save a lot of time and money.

One use case of UV prints would be vehicle vinyls where the prints get splattered with mud and dust on a daily basis. These prints also get washed and rubbed dry pretty regularly.

UV printed vinyls are generally able to withstand these daily rigors. Simply wipe off the dust and mud and your print will look as good as new.

UV Ink Printers Do Not Need Specially Coated Media to Print Upon

Printing media is manufactured with ink compatibility in mind. A particular roll of vinyl may be specially treated to receive solvent and eco-solvent inks. But it may not work for an aqueous ink printer.

Latex machines are able to print on a variety of uncoated/untreated media. But the machine generates a lot of heat to melt and fuse the latex granules. So even here, latex compatible media needs to be able to withstand very high curing temperatures.

This media compatibility issue means that a print shop needs to stock different media rolls for use with different inkjet machines.

But this is not the case if you’re relying on LED UV printing.

UV inks dry or harden, instantaneously on coming in contact with the print media. There is no time for the liquid inks to seep, run or blur. The curing process simply involves exposure to UV light and also does not employ any heat for the same.

This means that UV inks can be printed on just about any coated or uncoated substrate that you can think of.

In our aqueous inkjet section, we gave an example of photographs blurring on uncoated paper. The use of water-compatible, coated media was mandatory for achieving good results on water-based inkjet machines. A similar situation will not occur on a UV printer.

UV ink printing machines are media independent, in the sense that you can feed in just about any kind of paper or plastic in them and still be assured of a good print.

UV printers give you the freedom to print on coated or uncoated vinyl, raw sheets of plastic, or even an everyday roll of fabric.

For, as long as the media is in the form of a roll and can be fed through the machine, the UV printer will output high-resolution photo-quality prints on it.

UV Inks Do Not Need Heat to Dry

UV ink printers do not have any heaters as the inks do not evaporate in the traditional sense of the word. This leads to considerable savings in power, while running the machines.

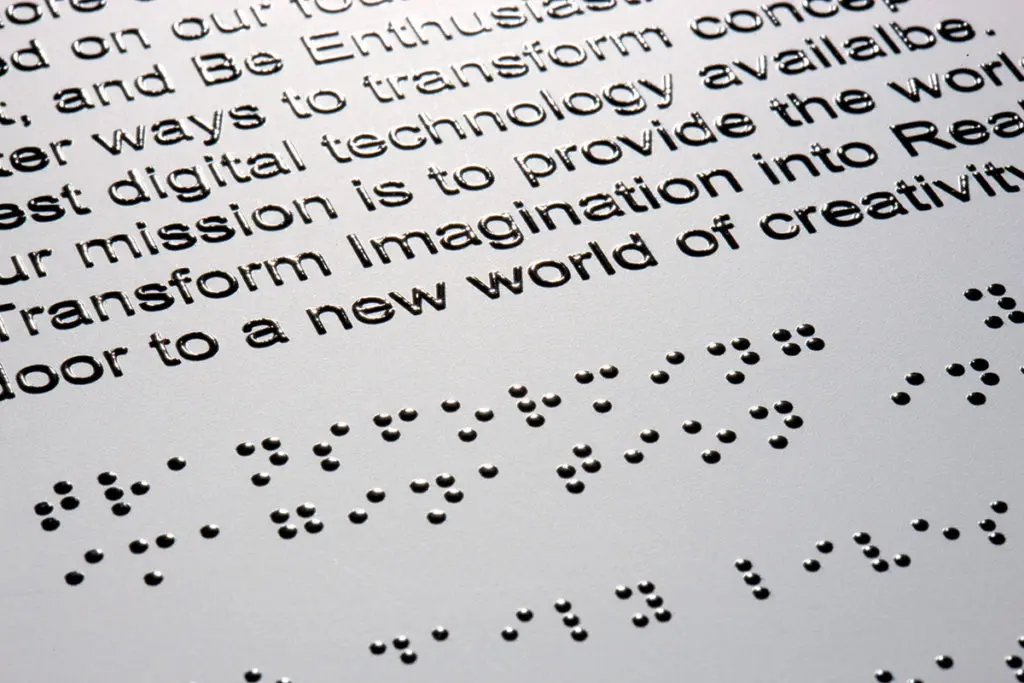

UV Printing Can Be Used to Generate Inks With a Raised 3D Effect

UV inks do not seep or percolate into the substrate they are deposited on. Since the inks dry instantaneously on coming in contact with the print media, they do not get absorbed in the same.

UV inks are left sitting on top of the print surface.

In fact, if you run your fingers over a UV print you will feel a separate layer of ink very slightly jutting or raised from the surface of base media.

Print providers use this property to generate prints with a raised 3D effect. They use a technique called ‘overprinting’ to do this.

Let us say, we want to give an embossed effect to just the logo in a large poster. To do this, the print heads repeatedly pass over the logo all the while adding more and more layers of ink on that location.

After a while, these multiple layers of ink, each deposited on top of the other, give a 3D embossed like effect to the print.

White Ink as a Special Color

White inks for eco-solvent printers have been around for some time now. But they have also failed for a variety of reasons. But now, with the advent of ultraviolet printing technology, whites inks have started gaining widespread acceptance.

Special applications like part opaque and partly transparent prints for glass partitions can only be created by the use of white inks. Please read more about this application of white inks, here. Apart from this, multi-layered prints and reverse film printing also require the use of white inks.

Clear Inks as a Special Color

In addition to white, UV printers can also be configured with clear inks. Clear inks are used to create an additional layer of clear film on prints. Moreover, this layer can have a gloss or matt finish.

Clear ink is used to give a spot lamination like effect to prints. Spot lamination means only certain areas of the print are coated.

For example, a visiting card may be wholly matte, but just the company logo has a shiny gloss finish. Thus clear inks are used to highlight certain areas of the image.

Comparison of Different Types of Inks – Characteristics, Benefits, and Disadvantages

Here is a chart that lists the strengths and shortcomings of the Aqueous, Solvent, Eco-Solvent, Latex and UV Inkjet Inks discussed above.

| Aqueous / water based inks | Hard Solvent inks | Mild / Eco solvent inks | Latex Inks | Ultra Violet (UV) inks | |

|---|---|---|---|---|---|

| Resolutions / Ability to reproduce high-quality images | Can output images at high resolutions | Outputs low-resolution images | Can output images at high resolutions | Can output images at high resolutions | Can output images at high resolutions |

| The location where prints can be used | Indoor | Outdoor | Indoor + Outdoor | Indoor + Outdoor | Indoor + Outdoor |

| Cost of inks and production | Low | Very low | Mid-range | High | High |

| Media Compatibility / ability to print on different substrates | Can only print on coated substrates | Can only print on coated substrates | Can only print on coated substrates but very wide range of media available in the market | The newer generation of latex printers have better media tolerance | Can print on any coated or uncoated substrate |

| Is a protective layer of lamination needed? | Yes | No | Prints are waterproof but lamination is recommended for scratch-resistance | Prints are waterproof but lamination is recommended for scratch-resistance | No |

| Speciality applications | Can only be used for photographic posters | Can only be used for outdoor hoardings and vinyls | Very wide media support for every application including textured, metallic, and cloth rolls | HP compatible media for wallpapers, canvas, fabric, etc. | White inks and clear inks enable premium job applications |

| Is print and cut / kiss cut option available | No | No | Yes | Yes | Yes |

| How mature is the technology? | Very mature. Enough engineers and spares are available. | Very mature. Enough engineers and spares are available. | Very mature. Enough engineers and spares are available. | Proprietary technology. Maintenance and spares available only at HP authorized outlets | Fairly nascent technology. Engineers for maintenance need specialized knowledge. |

| How much maintenance is required to maintain the heads and print quality? | Low maintenance | Low maintenance | Periodic maintenance is needed | Latex machines have a maintenance kit that you need to buy periodically. The same has to factored into your run costs. | Very frequent maintenance required. Inks will deteriorate if the machine is shut down. |

Wide-format Inkjet Printing As a Tool

It’s important for all of us to remember that at the end of the day, all these technologies and printers are mere tools and not Alladin’s Magic Lamp that spews out wealth and good things.

So, if you are a print provider, you need to understand and leverage these machines properly to the great results that will wow your customers.

I hope this post has helped clear your doubts about wide-format inkjet printers and the ink technologies prevalent in the market today.

The section on ink technology especially is intended to help upcoming printers make a choice about the printer they want to invest in.

This post serves as the 1st part in a 2-part guide on understanding wide-format inkjet printers and how they are a vital part of a digital printer’s arsenal today.

The second part of this series is especially relevant for you if you’re planning to buy a wide-format inkjet printing machine.

It talks about the various factors you should keep in mind before making a purchase decision on your wide-format inkjet printer. It highlights the pitfalls that you need to consider when you go shopping for a commercial printer.

We strongly recommend reading both these parts. Especially if you are an entrepreneur who is thinking of starting a digital printing business – the knowledge will come in very handy. And if you are already an established printer in the industry, then these posts might be a great place for us to start a conversation.

Finally, I’d love to hear from you. Do let me know your thoughts in the comments section below.

Share

Looking for any specific product?

Drop us a line. Send us your query. And we’ll get back to you with solutions and answers.

Mitesh Sanghani

Mitesh lives, mostly for Saturdays.

But when forced to work, you’ll find him heading Orchid Digitals – a printing press in Pune.

If it’s an emergency, try looking for him in the hills behind his house. You’ll almost certainly find him… lazing under a tree, with a book in hand.

Similar Blogs

Related Products

Vehicle Branding

Brand your vehicle with your company colours or your product images. Choose from low-end sticker solutions to high-end media specifically graded for vehicle wrapping. Reflective sticker media is also available. Plotter cut individual letters or logos. Install ACP boards on tempos or paste full-sized images on automobiles.

All our blogs

This is a section packed with useful knowledge on digital printing and its aspects, interesting printing case studies, and ideas, guides, and tips & tricks on marketing and branding.

I want to buy UV inkjet printer for my shop for job works specially replacing screen printing of wedding cards and other job works. Please suggest me as which type of Print Head is good for me with reference to cost, life and maintenance. What types of care should be taken to keep the print head healthy as to keep running print head for long time. There are many types of print heads are available in the market, I am going to choose mid format UV Flatbed Inkjet printer i.e. 3’x5′ size format. Thanks.

Hi Jayant. I don’t really sell printing equipment.

So perhaps I may not be able to pinpoint any particular brand.

But I will share my experience.

A. There are scores of machine options out there. Visit any decent trade show and your find the same.

B. Do not buy cheap chinese knockoffs. They will always prove to be costlier in the longer run.

C. Consider well known brands like HP, Mimaki, Roland, etc. You’ll have to study their different print head technologies and ink formulations to see which work best for you. But the brands are all pretty stabe and well proven.

D. Make sure that your agent / reseller has installed at least 5 – 10 machines in your city. If not, DO NOT CONSIDER this agent.

E. Check with other customers, how good the agents’ service and support is

For more clarity on the above, do have a look at this post on care to be taken before buying a new printing machine:

https://orchiddigitals.com/tips-to-buying-wide-format-printer/

All the best, in your new venture.