3D LED Acrylic Boards – 10 Different Types of Glow Sign Boards to Choose From

Eye-Popping Shop Boards to Impress Customers and Entice Them to Step in Your Store.

- Choose from 10 different premium shop-sign options

- Built using new-age material like acrylic, LEDs, and ACP

- 3D form-factor to highlight your logos and shop name

- Distinctive LED glow to attract customer attention

- End-to-End services including fabrication and on-site installation

- An investment that will yield major returns in terms of visibility

Share

Acrylic ACP LED Glow Sign Boards – Detailed description

In the consumer and retail store business, many customers make purchase decisions and judgements based on first impressions. That’s exactly why shopping malls are typically so glitzy and alluring. Shopfronts, building facades and store entrances are all designed to entice prospective clients to walk in.

And the primary component of your storefront is the shop’s signboard. In addition to showcasing your company’s name and brand, this signboard has to be so attractive, that it should literally stop people in their tracks.

Different kinds of boards serve different purposes and align with the way the brand positions itself. Blinking lights attract attention. Bright neon light signs in fluorescent colours stand out and create a festive, high energy, party-like atmosphere.

On the other hand, a signboard fabricated in gold-finished 3D letters conveys an impression of a store having rich and high-quality products.

Finally, you must’ve also seen large sky signs on the top of tall buildings. They make your brand visible for miles across the city skyline and end up becoming identifiable landmarks.

With the wide variety of signboards possible, one can choose an acrylic glow sign board that emulates the business entity’s personality. And the correct option can set the right tone and atmosphere to make business deals more conducive.

10 Types of LED, ACP Acrylic Glow Sign Boards Available at Orchid Digitals

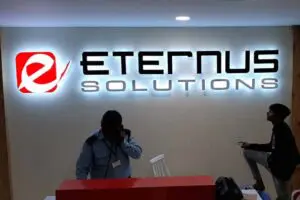

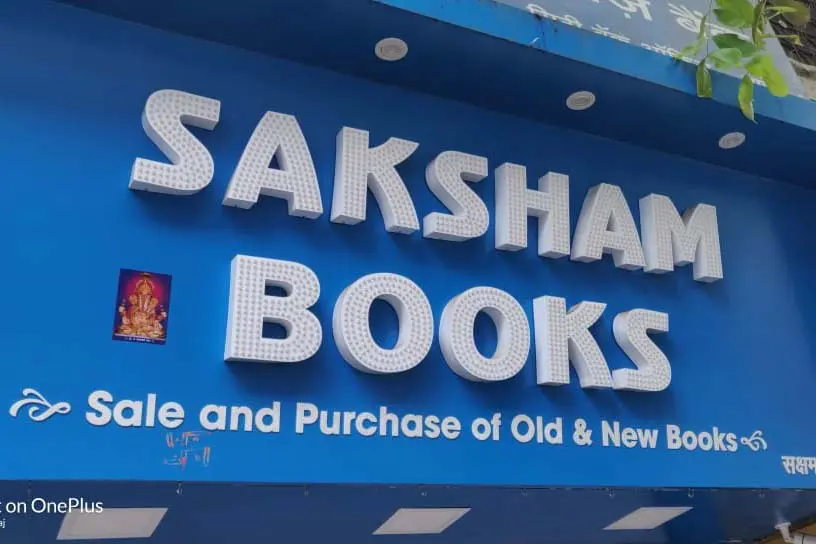

1. 3D Acrylic Letters Mounted on an ACP Base Frame

The letters on this board are made from laser-cut acrylic. They are mounted on an ACP frame and jut out approximately 3 inches from the base. LEDs are embedded within the letters to give them a beautiful glow.

Acrylic box letter boards are ideal for corporate offices and retail stores.

2. 3D Acrylic, Aluminium Channel Letters Mounted on a Base Frame

This board has a similar form factor like that of the 3D letter board, except for the fact the letters have a metal channel/profile on the side. The light glow comes only from the front surface.

Channel letter sign boards are ideal for corporate offices and retail stores.

3. 2D Stencil Cut Acrylic Letter Sign Boards

This type of board is used where the letters are very small or the content on the signboard is very intricate. The acrylic letters are not 3D but flush with the base-board. As the name suggests, the letters are hollowed out from the base ACP frame similar to how a stencil is cut from paper.

Stencil cut acrylic signboards are ideal for acrylic shop boards with a lot of content in addition to the name and logo. For example, timings, contact details, tag line, etc.

4. In-cut Acrylic Letter Boards

This board is similar to stencil cut acrylic boards. Here too, the ACP is surface is hollowed out, to fit the acrylic letters. The difference is that the letters jut out roughly 5 mm from the surface of the board frame. LEDs are fixed inside the board, under the acrylic letters.

In-cut acrylic boards are ideal for acrylic shop boards with a lot of content in addition to the name and logo. For example, timings, contact details, tag line, etc.

5. LED Acrylic Boards With Stand Alone 3D Letters Mounted Directly on the Walls or a Metal Frame

This sign is made of stand-alone letters only. The acrylic letters, in this case, are not mounted on any kind of baseboard. Further LED modules are embedded within the letters to make them glow. These letters can then be fixed directly on the wall.

This kind of sign board is ideal for corporate offices, retail stores, gate entrances having a pre-existing frame or wall where the letters need to fixed directly.

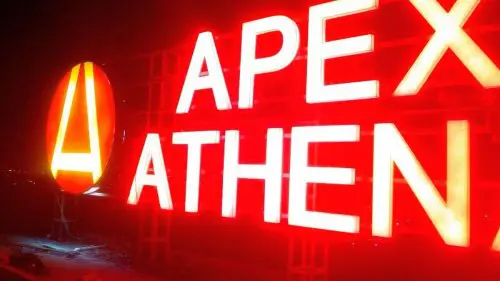

6. Robust Sky Signs for Tall Buildings

Sky signs are generally very large and visible from very distances. Particular care is taken to fabricate them from extremely robust material to strong winds and harsh weather conditions. Sky signs serve as markers to identify buildings.

And as such they are mainly installed at very high locations on multi-storey buildings.

7. Metal Letter Boards With a Back Glow

Metal letter signs look very classy and come in a variety of finishes like gold, rose gold, shiny chrome, brush finish, etc. Metal obviously does not allow light to pass through but the letters can be given a back-glow using LEDs.

Metal signs are used where light visibility is not a very important factor. For example – 5-star hotels, shop interiors, well-lit halls, etc.

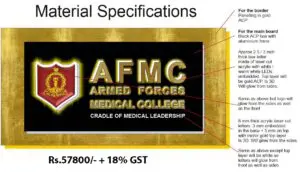

8. Sparkling and Glittering Crystal Letter Shop Boards

The 3D acrylic letters in these signs are embedded with hundreds of small crystals. Each crystal has multiple facets all of which strongly glitter to to make a highly decorative sign board with a lot of ‘bling’.

Crystal letter boards look very festive and are extensively used by jewellery stores, restaurants and ready made garment stores.

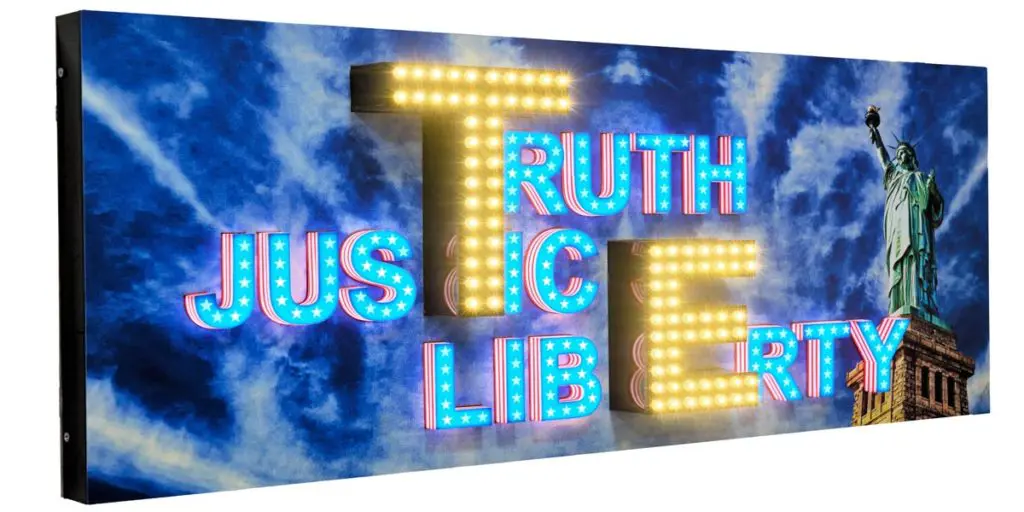

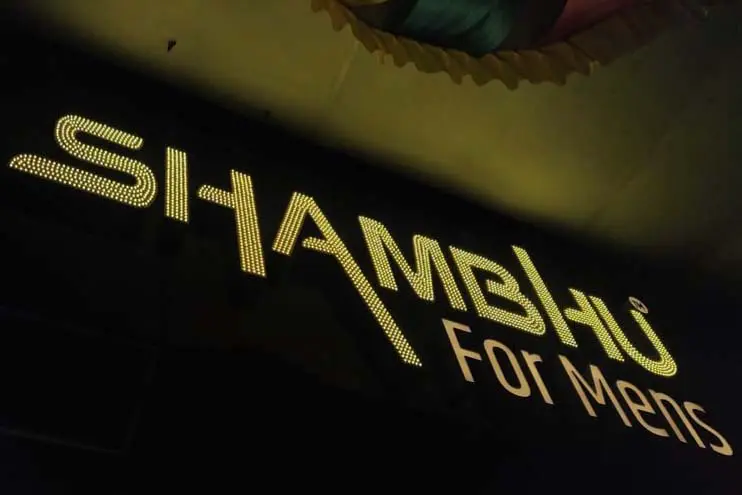

9. Intensely Bright and Strong Open Dot / Spot LED Boards

In this type of sign board the LEDs are fixed right on the top surface. The bright pinpoints of light are exposed to the naked eyes. The output from open dot LED boards is extremely bright and noticeable.

Open-dot glow signs is chosen by shop owners who really want their shop board to stand out, even at the risk of looking overly flashy.

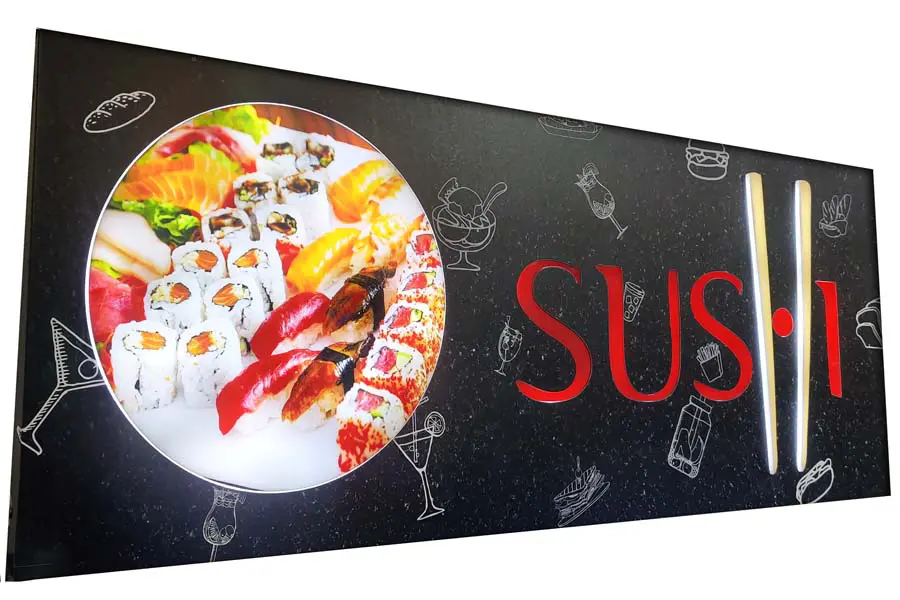

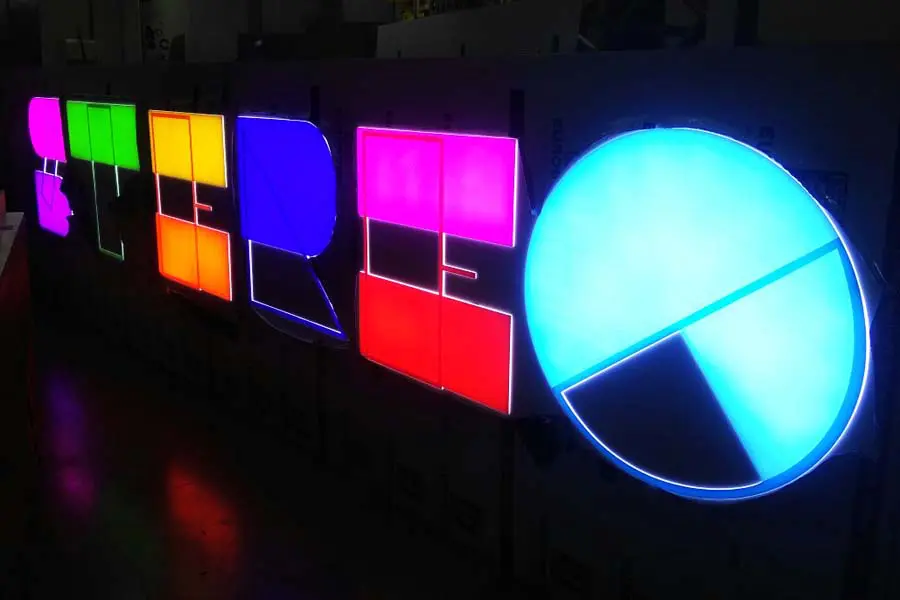

10. Neon Sign Boards Shining With Bright Fluorescent Colors

Neon signs have a typically bright unique and eye-catching colour. A throwback to the old glass tubes filled with neon gas, these signs are used to create text and letters which need to really stand out.

Neon letter signs are used in casual, high energy party locations like lounges, bars, discotheques, etc.

An Infinite Variety of Shop Boards

There is a whole album of ACP shades. Acrylic sheets are available not only on different shades but also in different thicknesses. And white or warm-white tints are the most frequently chosen LEDs. But here too, a customer is spoilt for choice. You can opt for:

- Fluorescent neon colours

- Blinking lights

- Very strong and harsh spotlights

- Programmable RGB LEDs, etc.

With so many different materials to choose from, innovative signmakers can come up with very interesting signs having a wide variety of form factors.

Do drop into our showroom at Shaniwar Peth and you will be able to check out LED acrylic shop boards having a beautiful 3D look where the letters and logos jut out 2 to 3 inches. We also have on display, two-dimensional boards having a stencil cut look where the letters are cut into the base ACP.

And if acrylic letter boards are not your thing, we can offer you metal letter signs in shades like gold, chrome, copper, rose gold, brush finish, etc. We also have Sky Signs which generally get installed on the top of tall buildings and need more robust materials.

Our more exotic sign-board section includes of letters made of glittering crystals, letters lit up in Open Dot LEDs, and even bright neon LED ropes. All of these options can contribute to the festive party look and celebratory ambience of a restaurant or night club.

Honestly, given the wide choice of colours, light effects, and materials to choose from, the types of backlit boards that can be fabricated is limited only by your imagination.

So this page covers an exhaustive (but non-comprehensive) list of the types of LED ACP acrylic sign boards that can be commissioned at Orchid Digitals.

The Right Kind of Shop Board for Your Business

Choosing the right kind of shop signs is very important. Today, there are many different types of acrylic glow sign boards available for all kinds of businesses…

- A business owner can opt for a lit or a non-lit board.

- He can choose to make a sign where the letters and logos are three dimensional and fabricated out of materials like acrylic or metal.

- Alternatively, one can have shop signs which are two dimensional wherein the matter is printed on a flat sheet vinyl or flex.

And these are just some of the options.

With so many choices, it’s normal for you to get overwhelmed and confused between what kind of shop-board would work the best for your business. Not to worry, we can guide you for it as well.

So this post is crafted with three objectives in mind:

- List the various types of the ultra-premium backlit signboards that modern signmakers have on offer.

- Highlight the characteristics, properties and differences between each of the types of signboards listed to enable you to make an informed choice.

- Talk about the materials that go into making the same, viz: acrylic, ACP (aluminium composite panels) and LEDs (light-emitting diodes) for the same.

As I mentioned above, this post covers the different types of high end LED and Acrylic ACP signage available in the market.

However, if you are looking for the more entry-level type of shop boards made out of printed flex and tubes in a metal frame, please click here. Also, jump to this post if you are looking for premium acrylic signage for offices without lights.

What Materials Are Modern 3D Shop Boards Made Of?

All signs generally have three main components:

- The base structure of the board. This takes the form of a metal box with a frame. At Orchid Digitals, we use a material called ACP – Aluminum Composite Panel for creating this base.

- The letters or logos that are installed on top of the base: These letters are typically fabricated out of a shiny glass-like plastic sheet called acrylic.

- The light components embedded inside the letters or in the base-board to give colours and light effects to the above-mentioned acrylic letters. Modern signs are generally lit up by LEDs

You can read the detailed description of the materials, above components and construction process of the boards in a section at the end of this page. It does make for an interesting read.

But for now, let’s explore the different kinds of boards listed above, in detail:

Detailed explanation and photos of 10 different kinds of LED ACP Acrylic Glow Sign Boards

1. 3D Acrylic Letters Mounted on a ACP Base Frame

Three-dimensional letters fixed on top of an ACP base is the type of sign board that most store owners opt for. As the name suggests, these acrylic name boards consist of:

- Hollow acrylic letters or logos which are approximately three inches thick.

- LEDs are embedded in the hollow space beneath these letters.

- These 3D letters and logos are mounted on an ACP box frame.

- This aluminium frame, along with the backlit acrylic letters, are then installed on-site.

How is a 3D Acrylic Letter Board Made?

- First, a customer provides us with an artwork containing the design and dimensions of the letters and logo for the signboard. To create 3D acrylic letters from this artwork, we use a laser cutting machine.

We cut the requisite shapes from a flat sheet of acrylic having 3 mm – 5 mm thickness. These shapes are then extruded in 3D using a method called skirting.

Skirting is nothing but fixing a vertical, perpendicular acrylic border to the flat laser cut letter on top. This side skirting is approximately 2.5 inches to 3 inches in thickness.

- We now have a hollow 3D box with an acrylic strip on the sides and top surface. Small LED modules can now be fitted in the hollow space beneath the 3D letters.

Since the letter is entirely made of acrylic, it allows light to pass through from the front as well as the sides. The end result is a stunning, well-lit logo or letter for our signboard.

- This glowing box letter, along with its embedded LEDs, is then fitted onto the ACP base frame. And finally, the finished base frame is mounted on top of the storefront.

As I mentioned previously, both ACP and acrylic sheets are available in a variety of colours. Obviously, the colour of these sheets needs to be matched with the brand and corporate guidelines of the client.

The End-Result and Application

The resulting LED acrylic letter board has two different effects ideal for both day and night times.

- During the day, the colourful ACP frame is beautiful to look at. Additionally, the 3D logos and letters jut out in the front and give a very premium look even when the board is not lit up.

- At night, when the power is switched on, these same letters and logos brightly light up with the embedded LEDs and give a stunning look to your shop front.

2. 3D Acrylic, Aluminium Channel Letters Mounted on a ACP Base Frame

Channel letter signs are almost exactly similar to acrylic box letters. Here too, we have a raised 3D letter with LEDs fixed on the inside. But there is one major difference.

In acrylic box letters, both the front as well as the side skirtings are made of acrylic. This means that the entire letter (the top surface as well as its 3 inch deep sides) glow when lit from within.

But that is not the case for a channel letter board.

How is a 3D Acrylic Channel Letter Board Made?

In 3D channel letters, the side border is made of a metal patti or strip. Signmakers refer to this border as ‘aluminium profile strip’ or ‘channel patti’.

For fabricating our letter, we take a 3-inch thick aluminium channel and turn it into the desired shape. There is a specialised channel bending machine to do this. The laser-cut acrylic sheet is then mounted on top of the shaped channel.

The End-Result and Application

The end result is an exceedingly beautiful letter with a metallic finish on the sides. With the acrylic sheet on the front, you still have your backlit effect. The only difference being that the letter will glow only from the front and not from the sides (being made of metal, the aluminium channel does to allow light to pass through.

Choosing between a fully glowing acrylic box letter sign board and the aluminium channel letter option is a matter of personal choice. The costs for both are more or less the same.

A sign board is not lit during a major part of the day. So, for some people, the metallic finish of a channel letter is more important than the amount of light it throws out. Others might prefer the glorious glow of the entire 3D letter. For them, it would make sense to opt for the acrylic box letter sign.

3. Acrylic Glow Sign Boards with Stand-alone Letters Mounted Directly on the Walls or a Metal Frame

An aluminium composite sheet provides us with a base to mount our lit acrylic letters on. But in many use cases, customers ask us to do away with this base ACP frame entirely. We are requested to mount the letters directly on the wall or an existing metal frame.

Stand Alone Acrylic Letters With Lights. Why Are They Needed?

Assume for a moment that the customer has a well-finished wall of granite. It makes no sense for us to cover his premium looking granite tiles with yet another layer of aluminium composite panel.

Alternatively, the client may have an existing metal frame or steel girders in place at the installation site. Our job is to then reduce his cost by installing the 3D letters directly onto this frame. Doing away with the base frame does help in saving money.

In many malls, you’ll see glowing letters hanging from the ceilings without any visible back support. Standalone letters shining in front of the glass facade of premium retail stores add to the aesthetic value of the same.

Two Prerequisites for Stand Alone Acrylic Glow Sign Board.

Stand-alone letters jobs come with a couple of conditions. Fulfilling them. Will result in a beautifully finished job. The two things we pay particular attention to are…

- We need to connect an electrical wire to each individual letter or logo of the sign. Remember, these letters have LEDs encased inside. Power needs to be supplied to these LED modules. In the case of an ACP base frame, the wires are easily concealed behind the metal panel.

But exposed wires do look ugly if there is no place to hide them. To work around this issue, we back drill on the wall where the letters have to be installed. This means we make a small hole behind each letter and loop the wires from behind the walls.

In case the letters are installed on a frame, we hide the wires in the structure’s hollow metal pipes.

- Since there is no proper base or support for our letters, we prefer to use thicker and more robust materials to fabricate the signage. The letters are still made of laser cut acrylic, but we may choose to opt for a 5 mm thick sheet in place of the more standard 3 mm.

But while the front and sides of the letters are made of acrylic, to allow light to pass through, the back surface/base of regular letters is generally cut out of a 5 mm thick sunboard. For stand-alone letters, we recommend the use of a metal / ACP sheet for the back surface.

These best practices ensure significantly enhanced strength for our 3D letters. Crosswinds on high rise buildings pose a very real danger that needs to be considered by sign makers.

I have personally witnessed gale force winds tear apart a huge, 40-feet board, from the seventh floor of a high rise.

While thankfully no was injured in that incident, it highlights the fact that fabrication and installation of shop signs should be commissioned from agencies with some level of experience rather than blindly contracting out the job to the lowest bidder.

4. 2D Stencil Cut Letters in an ACP Box / Base Frame

The acrylic letters are three dimensional in all the three types of LED acrylic sign board options mentioned above. They jut out a few inches from the base on which they are installed.

But we can also fabricate boards where these glowing acrylic letters are in the same plain as the surface they are mounted on. These backlit letters do not protrude and are in line with the base ACP frame. Our letters now have a two-dimensional effect.

How Are Stencil Letters Cut Into an ACP Panel? How Is the Board Lit Up?

Stencil cut letters, as the name suggests, are cut into the base ACP sheet. This is done using a CNC router. Let’s say that you need to cut a sign in the shape of the letter “A”. Signmakers make an “A” shaped hole in the metal sheet which goes into the making the base frame of the board. This hole is cut out using the drilling tool of a CNC router.

Remember the arts and craft class back in school when we used to cut stencil designs from paper using a blade? This process is pretty similar.

We then cut another letter “A” in the same shape and dimension of our ACP sheet’s ‘A’ shaped hole. This time the letter is made of a 3 mm thick acrylic sheet. Please also remember that acrylic is translucent and allows light to pass through.

Our laser cut acrylic letter is then precisely slotted into our “A” shaped hole on the metal sheet. LED modules are fitted in the hollow space of the ACP frame, beneath the acrylic letter. These modules make our 2D stencil cut acrylic sign glow and light up.

Why Would I Choose a 2D Stencil Letter Board in Place of a 3D Acrylic Letter Board?

You are probably wondering why people would opt to make signages in 2D as against the 3D options listed above? Here are several reasons why…

- Acrylic glow signboards with two-dimensional letters are cheaper to fabricate than 3D acrylic signs. The end cost that a customer has to pay for this option does come down.

- Architects and designers like to play with the heights of different elements on a sign. So they might choose to keep some of the elements on the signboard in 3D and others in two dimensions. Let me illustrate this by giving you an example.

Let us say your sign is made up of three elements. Your logo, the name of your firm and the tagline of your company. Obviously, all three of these elements are important since they are being put on the main shop board right outside your store.

But perhaps the name and logo need to be highlighted a bit more than the accompanying tagline. In this case, a designer would go for a larger font size and higher placement for these two elements vis-a-vis the tagline.

Moreover, the letters making up the name and logo would be fabricated in the more prominent 3D acrylic name board option. In contrast, the tagline would be restricted to a flat two dimension.

Our sign is composed entirely of lit up, glowing letters. But some letters (the name and logo) are highlighted more strongly by virtue of giving them more depth and making them jut out from the base surface. The tagline also looks pretty bright. But it is kept relatively subdued because it is stencil cut in just two dimensions.

Apart from pushing the more important elements forward, this play of differing heights on a signboard also looks more aesthetically pleasing. - Sometimes signboards are installed indoors. For example, the signs that you see in a bar or on the wall behind a hotel’s reception area. These signs are installed at eye level, and if the letters jut out significantly, they might brush or hit against people walking past them.

The less accident-prone, flat 2D glow signs then become the preferred option in this use case.

- 3D acrylic letters have LED modules embedded in the hollow space beneath them to impart a backlit glow. These modules are generally 35 mm in width. This means that signmakers need at least 2 inches of free space (width), beneath the letters, to install the same.

Most fonts on large boards have a width larger than the requisite 2 inches. And our LED modules can easily be installed in this gap. But there are cases where the board design is pretty intricate.

A particular font may be pretty thin and not wide enough to accommodate our LED modules. In this case, we need to opt for 2D stencil cut acrylic letters for our sign.

5. In Cut Letters in an ACP Box / Base Frame

In Cut Acrylic Letter signs are pretty similar to Stencil Cut Letters. Here too, a laser cut acrylic letter is pushed into a same shaped hole in the base ACP panel. There is one small difference though.

In Cut Acrylic Letters Are Very Slightly 3-Dimensional

In Cut acrylic letters are not two dimensional like their Stencil Cut siblings. The acrylic letters, in this case, protrude very slightly away from the base acrylic frame. Where stencil letters are used, the acrylic letter, which is embedded in the ACP cavity has the same thickness as the ACP sheet. So both these elements remain in the same plane.

In-cut letter boards use an acrylic sheet significantly thicker than the aluminium composite panel. The letters, in this case, become taller than the surrounding metal sheet. Let me elaborate on this.

ACP sheets are generally 3 mm thick. So when we make a hole in the same, the cross-section/hole also has a depth of 3 mm. Moreover, standard acrylic sheets used for sign making have a thickness of 3 mm. So when a 3 mm laser cut acrylic sheet is pressed into a 3 mm deep ACP cavity you end up with the ACP sheet and embedded acrylic letter having the top surfaces at the same height.

Run your fingers over the ACP panel and embedded letter and both these objects will be at the same plane. Your finger will not encounter any protrusions. This is why stencil cut acrylic signs are two dimensional.

But let us suppose that in the above example, we fit a 10 mm thick acrylic sheet in our 3 mm deep ACP cavity.

Now we end up with the letters protruding 7 mm (approximately a quarter on an inch) above the flat plane of our metal sheet. This is because, out of the total 10 mm thickness of our acrylic letter, a depth of 3 mm gets embedded in the ACP sheet. The remaining 7 mm juts forward.

In Cut and Stencil Cut Acrylic Letter Boards Are Largely Similar

In cut acrylic signs look very rich. These acrylic letters of course have a front glow. But additionally they also have a very nice edge glow from the sides that are protruding forward.

Opting between Stencil Cut and In Cut letters is a matter of individual choice. All the use case scenarios that apply to Stencil Cut letters stand true for In Cut acrylic signs as well.

In Cut acrylic letters can be deployed to impart a play of differing depths to the various elements on a backlit sign board. They too are used extensively for indoor signs. Moreover, just like Stencil Cut letters, the In Cut acrylic option is used to fabricate boards having very thin fonts or an intricate design.

6. Sky Signs

Three-dimensional acrylic, custom LED signs are very frequently referred to as Sky Signs. While the materials and methods used in creating sky signs are mostly similar to the ones used in other acrylic shop boards, the term ‘Sky Signs’ has a slightly different connotation in the signage industry. Let me explain why.

Use Case Scenarios for Sky Signs

Sky signs, as the name suggests are installed at very high locations. Ten storeys and higher buildings have become the norm in many Indian cities and there is an increasing demand for signs to be installed on top of the same. The reason is obvious. The higher a sign is installed, the greater its visibility.

Large signboards on top of skyscrapers can sometimes be viewed from kilometres away and have the potential to become prominent identifying marks on a city’s skyline. Drive down the expressway heading into Pune city and you will see huge signs atop tall buildings on both sides of the road.

Challenges in Executing a Sky Sign Project

Sky Signs, as a separate category in the signage industry, have some unique characteristics, such as:

- The size of the letters and logos on a sky sign are significantly larger than the ones installed on storefronts. We routinely fabricate individual letters of 6 feet, 8 feet and even larger. An average 15 storey building shoots up to almost 200 feet in the air.

Signs on the shops at road level have letters of 2 or 3 feet at the most. But 3-feet high letters would become insignificant and in fact, almost invisible when installed on such a tall building.

- We also need to use stronger, thicker, heavier and more robust materials to account for this increase in the size of the letters.

- Moreover, sky signs are generally exposed to very high-speed winds all year round. Gale force winds at elevated locations can play havoc with signs. There have been instances of the wind unmooring or uprooting letters from their base.

- Open to sky signs are also significantly impacted by rain and harsh sunlight. Signs need to be fabricated out of materials that do not corrode. Moreover, the electronic components of sky signs, namely the LEDs, the power supply and associated wiring all need to be waterproof to avoid short circuits and fire hazards.

- Installing a sky sign on the side of a tall building can incur an additional cost of scaffolding. Accessing high places is difficult. If there are no means to reach the outside wall on the seventh storey of a building, we need to get a ‘pahaad’ or bamboo scaffold erected to do the same.

You need to keep this factor in mind when planning for your sky sign job.

How Are Sky Signs Fabricated at Orchid Digitals

At Orchid Digitals, we take particular care when commissioned for Sky Sign projects. Here are the points that are generally addressed.

- Robustness of the signs: Sky signs are almost always made of aluminium channel letters. The aluminium profile used is also pretty thick. When the sides and back of the letters are made of metal, the letters become extremely strong. The acrylic sheet fixed on the front of the letter has a thickness of 5 mm in place of the more standard 3 mm. The materials’ thickness and strength ensure that our sky signs do not crack or break in adverse weather conditions.

- Since the individual letters are made of aluminium, they do not corrode or degrade over time.

- The LED modules and driver (power supply) that go into making our signs have an IP67 rating. This means that they are waterproof and will not get damaged on exposure to water.

- We deploy a scaffolding team for fixing Sky Signs on the sides of buildings, and ‘jhoolas‘ or platform lifts suspended from ropes. I even remember one hotel sign project on Baner Road, where we brought in a crane to hoist a heavy 6-foot circular-shaped sign, 4 storeys high.

7. Metal Letter Boards

In all the types of LED acrylic sign boards described above, the letters or logos of our signs are made of acrylic. This is because acrylic allows light to pass through. Using different colours of acrylic, we can have a backlit signboard in a variety of shades and light effects.

In our introduction to this post, I also argued that backlit sign boards are commissioned due to their high visibility. People pay top dollar to make their brand stand out as much as possible. In fact, we enthusiastically cram in as many LEDs as we can in a backlit signboard to give it the maximum amount of glow.

But there are certain situations where the light glow and visibility of a shop sign are not as important as the need to impart a very sober and rich look. The effect I am talking about is more subtle and less ‘in your face’. Enter metal letter sign boards.

One Advantage and One Disadvantage of a Metal Letter Board

The Advantage – As the name suggests, metal letter signs are made of iron or stainless steel. These letters can be anodised to have different colours and finishes like chrome, gold, copper, rose gold, brush finish, etc. In fact, this anodised finishing of metallic letters is unbeatable in terms of look and feel.

The Disadvantage – The only drawback of metal letters is that it does not allow light to pass through. So, we recommend that these signs be installed in areas where light visibility is not as important as the need to create a premium effect.

A five-star hotel’s lobby for example is probably already very well lit from hundreds of different light sources. A sign in this location need not be backlit. So many interior decorators would opt for a highly polished, rich looking metallic sign here

Metal letter signs can be given a very beautiful back glow effect. As explained above, metal in itself is not transparent, duh! So what we do is, we do not install the letters flush with the wall.

Instead, the letters are raised a couple of inches away from the wall using spiked nails. We then put in a flexible LED rope beneath the letters. The light modules are kept facing the wall.

When switched on, the LEDs give a beautiful back glow effect, wherein light shines from the beneath the letters and from its sides. The letters themselves remain dark and silhouetted against this back glow. Do take a look at images of this shadow effect that I am talking about.

8. 3D Crystal Letter LED Boards

When you light up 3D acrylic letters, you get a very bright and even glow from the sign board. Moreover, if the acrylic is coloured, we get a similar shaded glow. And these kinds of light effects are ideally suited for most shop fronts and corporate offices.

But there are some businesses which demand, for want of a better word, more ‘bling’ from their signage. A hotelier, a ready garments store owner and jewellers especially look for more embellishment on their shop signs. And 3D Crystal Acrylic sign boards fit this bill perfectly.

How Do We Make Letters That Merrily Glitter and ‘Chamak’?

Instead of acrylic which evenly diffuses the LED glow we use hundreds and even thousands of small glass crystals in our sign letters. And these crystals disrupt the light emitted by the LEDs fitted beneath.

Each of these quarter inch crystals have multiple facets. And each of these facets create their own tiny focal point angling the light beam at thousands of different angles. Our crystal letter sign ends up glittering and shining very much like an expensive Swarovski chandelier.

For making crystal letter boards, we need to make a small change in the way we fabricate our acrylic box letters. The front surface of this letter has to be transparent like glass. We then glue small crystals on the back of this clear acrylic sheet. We push in one more sheet behind the crystals, to hold them in place.

The LED modules are placed beneath the crystals (inside the acrylic letters) just like we do for all other signs. Our white crystals are now in place and can be individually seen during the day when the lights are off. At night, when the power is switched on, each of these hundreds of crystals starts glittering to give a stunning effect to our sign board.

Crystal Letter Boards Are Ideal for Jewellers

Jewellery store owners especially love the sparkling diamond-like effect of Crystal Letter Signs. Further, they ask for the sides of these letters to be made of metal with a gold or rose gold finish.

The look of this ‘gold’ letter sign with sparkling ‘diamond’ lights ends up closely representing the ornaments they are selling!

9. Open Dot LED Boards

In all the boards described above, the light source, i.e. the actual LED modules, are always concealed. Think of an LED as a single bright pinpoint of light. In the above types of boards, this pinpoint is hidden beneath an acrylic sheet, covered by a metal letter or occluded by lots of miniature crystals.

Each of these methods also gives off different light effects. For example, an acrylic sheet evenly diffuses the glow, and metal letter signs enable a back glow effect. Letters adorned with crystals, on the other hand, give a unique sparkling effect.

But at Orchid Digitals there is an option of creating a signboard without having to hide the individual dots of glowing LEDs.

We can fabricate letters where the individual LEDs can directly be viewed. These signs, where the lights are not covered, are known as Open Dot LED boards or LED open signboards.

The Advantage of an Open Dot LED Board

The single biggest advantage of Open Dot boards is that the light thrown out by these signs is phenomenal. Since there is no cover on the LEDs, the full power of their luminosity is brought into play.

Each LED module is a pinpoint of light. The viewer can see hundreds of these pinpoints or spots of light. That is why these signs are also referred to as Spot LED boards.

I want to once again emphasise how bright Open Dot LED boards can become. There have been instances where high powered street lamps pale in comparison to these signs.

At dusk, when Spot LED boards are switched on, the roads and mohallas visibly brighten up. This extreme brightness can also backfire on us. One client actually came back to us with a complaint that viewers get dazed when they glance at their LED open sign board.

How are Open Dot LED Boards made at Orchid Digitals?

To fabricate a custom Spot LED sign, we first create a regular 3D acrylic sign. We then drill small holes on the top surface of the acrylic letters. Individual LEDs each measuring 8mm in diameter (or even smaller) are slotted into these holes.

Instead of being embedded under the acrylic cover, each dot of LED remains exposed. Hundreds if not thousands of these dots are placed closely together to make a single shop sign. And when these thousand-plus dots all light up, the effect is truly awesome.

Standard LEDs emit light in a single colour. But RGB LED modules are a variant of the same where one dot can glow in many different colours. Custom acrylic LED signboard manufacturers use a special programmable driver/chipset to make all the LEDs cascade through different colours simultaneously.

We can even program the LEDs to create interesting patterns. RGB LEDs are used extensively in LED open signboards. These signs then come ‘alive’ through a riot of colours, patterns and light effects.

10. Neon Sign Boards

A very specific type of LED acrylic signs are the neon signs. Technically speaking this is a bit of a misnomer. Previously, people used to fabricate signs out of glass tubes filled with neon or argon, xenon, helium and other noble gasses. These gasses used to light up with the typically bright and fluorescent colours we are all familiar with.

But neon lights were very difficult to maintain and consumed huge amounts of power. The glass tubes were prone to breakage. Also, the gas used to frequently leak out of the glass tubes it was encased in. Do you remember seeing neon signs where one of the letters was flickering or had gone completely dark?

Depicting a seedy rundown motel by opening the scene on a partly dark or flickering sign is a trick used in many Hollywood movies. Such broken down signs did attract attention, but for all the wrong reasons. With the advent of low-cost, low power consuming, and long-life LEDs, glass tube signs quickly became obsolete.

But the neon lights used decades ago had one thing going for them. Their bright fluorescent lights emulated colours straight out of a science fiction movie. These colours brought a festive party-look to their surroundings.

Neon signs were phenomenal attention grabbers. They have always been in great demand in places like bars, lounges, restaurants, fashion salons, etc.

The ability to grab attention is the reason sign makers like us get paid :-). Customers started demanding a solution for very bright coloured signs with low power consumption and none of the maintenance hassles inherent in gas-filled glass tubes.

The time was ripe for LEDs to fill in this demand gap, and LED manufacturers did not disappoint. And, they did so with an ingenious solution.

LED Neon Ropes – A More Modern and Energy Efficient Solution for Neon Light Signs

Neon glass tubes have been difficult to make and maintain, and thankfully, replaced of late by LED ropes. These ropes are tubular and can mimic the running, script letter form of older generation neon signboards.

But most importantly, these neon LEDs are available in beautiful eye-catching colours like fluorescent green, bright orange, peppermint blue, fluorescent pink, royal blue, etc. Also, since these ropes are made of flexible plastic as against glass, they are not prone to breakage. Moreover, neon LEDs consume a tiny fraction of the power of their glass tube counterparts.

LED Neon Signs Boards Can Only Have a Running Font Form Factor

Do remember that neon LEDs ropes are thin half an inch thick flexible tubes. So we can fabricate thin running font letters out of the same. But if your sign design is made up of thick blocky fonts, you might have to opt for the more conventional acrylic letters.

Moreover, what is a bright colour for some, may be too garish for others. A fluorescent pink letter might not be appropriate for a sober corporate sign. Use neon colours when you want to give a high energy, youthful look to a low-lit lounge bar. But you might be sending across the wrong message if the same were to be installed outside a doctor’s clinic.

Do have a look at the images showing examples of LED Neon signs boards.

What Are the 3 Main Components of a Glow Sign Board?

Reading this section will give you in-depth knowledge about the materials and construction process of acrylic ACP glow signboards. Please click on the accordion tab below to know more.

On the other hand, you can choose to skip this section and see how your shop board project can be taken forward.

Base of the Sign

The base of the sign (or the actual board) on top of which all the letters/logos are installed is generally made of two components.

- An aluminium frame out of 3-inch thickness. This frame is made of square pipes of aluminium. The industry refers to them as aluminium sections or profile patti.

- This ACP or aluminium composite panel is a 3 mm thick sheet which is stretched or moulded across the frame described above. As the name suggests, ACP is a sheet composed of two layers of aluminium foil sandwiching a thick rubber liner in between.

The end result is a box of three inches depth. This depth is sufficient enough to conceal all the electrical wirings and acrylic letter fittings.

The box frame is screwed on to the wall at the installation site. All the other components like the glowing letters, the LEDs associated with the same, etc. are fitted on top of this box frame.

The benefits of using sheets of aluminium composite panels for outdoor signages are:

- ACP sheets do not rust as neither aluminium nor rubber oxidises or corrodes.

- ACP sheets have a fabulous finish. It is smooth and flat. When moulded around a frame, one can get extremely straight edges. All in all, ACP sheets have a significantly better form factor than other signage materials like patra or tinfoil.

- ACP sheets are available in a variety of colours, metallic tints and even wood finishes. This choice of shades makes it easy to match the custom signboard with the clients’ logo colours or brand identity.

- Using a CNC router, it is very easy to cut letters and logo shapes into ACP sheets. This is important because the next step in fabricating our board is to place LEDs in these cuts for illumination. Thick acrylic letters are then mounted over the LEDs for the backlit 3D effect

Acrylic Letters

Acrylic letters are the second and the most visible component of our LED acrylic shop boards. All letters, logos, tag lines, etc. fitted on top of the ACP base frame are generally made of acrylic.

LEDs concealed behind these acrylic letters act as the source of light for our acrylic ACP glow sign boards.

Acrylic is a very high-quality sheet of plastic which can replace glass in a variety of products. It has the look and shiny finish of glass. But unlike glass, acrylic is extremely lightweight. Since it is made of high-grade plastic, unbreakable and will not crack or shatter like glass.

Perhaps the most important property of an acrylic sheet is that it can be easily shaped, moulded and cut in just about any shape you desire. Moreover, we can even extrude (give depth) acrylic sheets to create hollow three-dimensional designs.

For example, let us assume that we need to create a backlit sign of the letter ‘O’. We first use a laser cutter to cut out an ’O’ shaped design from a flat 3 mm thick sheet of acrylic. This flat sheet is then given a depth of about 3 inches. We now have a hollow 3D letter.

Small modules of LEDs are fitted in the hollow space beneath the letter. The end result is a beautiful glass-like letter which glows from within when the power is switched on.

To summarise, acrylic has the following properties which make it the ideal material for creating backlit signs:

- Acrylic is smooth and has a very glossy glass-like finish.

- Moreover acrylic is extremely strong and less prone to breakage.

- Acrylic is significantly lighter in weight when compared to glass.

- For creating 3D signs acrylic can be easily cut and moulded. It is pretty easy to fabricate acrylic letters in just about any shape or to reproduce logos and fonts specified in a client’s artwork.

- Acrylic is available in a variety of colours. In fact, there is a whole album/shade card of colours for you to choose from. Matching logo colours as per corporate branding guidelines is a breeze.

- Acrylic allows light to pass through. So 3D letters made out of acrylic can be embedded with LEDs to give it a backlit effect.

LEDs – Light Emitting Diodes

LEDs – Light Emitting Diodes are the third main component that goes into making our LED acrylic glow sign boards. A backlit glow is what gives the added punch to any signage. Look at the skyline of a modern city and you’ll see bright neon signs on tall buildings. Walk down a city’s high street or business district and you notice that the lit boards are the ones that attract your attention the most.

Light, obviously, is what enhances the visibility of any 3D acrylic light board for shops.

Incandescent bulbs, fluorescent tubes and unwieldy gas-filled neon tubes were used to light up sign boards for the longest time. But of late, all of these options are being replaced by LEDs or light-emitting diodes.

Think of LEDs as tiny pinpoints of light that can be fitted in the smallest of places on our custom LED sign board. Despite their small form factor, LEDs give a significant bang for your buck. The illumination a single LED provides is far greater than any conventional light source of the same size.

The advantages of LEDs over traditional lighting methods are so many, that it’s safe to say that the LED did to the light bulb what mobile phones did to the humble landline telephone.

- LEDs consume a fraction of the power used by traditional light sources. This leads to huge savings on the electricity bill. This is significant because custom backlit LED sign boards are typically switched on from dusk or late afternoon to the wee hours of the following morning.

- LEDs do not heat up. With no heat, the power requirements of an LED plummet when compared with, say the traditional light bulb. But more importantly, the absence of heat addresses a huge safety issue.

When it comes to acrylic LED sign boards, the chances of boards catching fire due to the excessive heat generated by the traditional light bulbs is completely negated.

- For all practical purposes, LEDs are immortal. LEDs can have a lifespan measuring in excess of 50000 hours. This means that even if you light up your custom LED sign board for 6 hours a day, you can expect the LEDs to keep shining for the next 20 years! Older sign boards need periodic replacements of their light sources. LEDs have completely voided this hassle.

- LEDs have a very small form factor for the luminosity that they can generate. A 35 mm LED module can typically generate as much light as a 2-3 inch bulb.

- Due to it’s small size, a signboard manufacturer can typically fit more LEDs in a board to make it significantly brighter.

- Moreover, modules measuring less than an inch can be fitted in the tight spaces, corners and curves of a logo or font. For example, let’s say the letter ‘A’ in a customer’s design measures 12 inches. There is no way to fit a 3-foot long fluorescent tube in this letter. The only way to light up this small letter is to use miniature LEDs.

- There is a variant of the standard LEDs known as RGB LEDs. RGB diodes are capable of emitting different colors as against the vanilla LED option that shines in one single shade. Signboards fitted with these RGB LEDs can be made to cascade through all the colors in the spectrum. We need a special programmable chip to make this happen.

But the fact remains that multiple varieties of colours and dancing lights make our custom acrylic LED sign board even more eye-catching.

I can keep going into more detail about the materials and fabrication processes of sign boards. But for now, let’s talk about how to initiate a glow sign project at your premises.

How Does a Shop Sign Project get Executed at Orchid Digitals

If you even skimmed through the content above (or glanced at just the images) you must have realised that there are far too many different combinations and possibilities in creating a shop light board. For the same design, you can vary materials and specifications like 3D or 2D letters, glass like acrylic finishes, brushed metal tints or even the more exotic options like crystal letters and open dot LEDs. Each of these materials has a different costing that needs to be calculated once the specifications are finalised. So there’s really no standard answer to the question – What is the cost of a backlit glow sign board?

The 2 Cost Components of a Sign and Shop Board Job

The cost of an LED acrylic sign is made up of two components. The cost of the actual materials used plus the cost of coming over to your place and installing the same. A twenty foot sky sign or even a eight foot shop board is not a product that we can place in your hands across our office counter. We need to come visit the site where the final installation has to happen. Space available for installing the backlit board needs to be accurately measured.

Installing a board on tall buildings and very high locations comes with its own set of challenges. Specialized equipment like scaffolding, raised platforms or even a crane may be needed to hoist the sign in difficult to reach places.

Finally we need to discuss with the customer about the best choice of materials given the nature and requirement of their job. It’s also important for the customer to be able to visualise what the final job is going to look like. This is necessary in order to avoid any rude surprises later on. Once the job specifications are agreed upon, we are in a position to work out the cost for the same.

The Procedure We Follow When Asked for a Quote

Keeping all the above complexities in mind, Orchid Digitals follow a few predetermined steps when commissioned for a signage job

- Reconnoitering the installation site: This is necessary to check how easy (or difficult) it is to install the board at the given location. We also double check the measurements given to us by the customer and ascertain if a board to that dimension can fit in the available space.

- Finalising the layout / artwork of the sign: While most architects give us ready designs, some customers only have a logo file at their disposal. Incorporating the logo along with the name and tagline is the next step after the dimensions are agreed upon.

- Finalising the material specifications: If you care to drop in at our store, we have a ready display of all the kinds of acrylic light boards described above. We also have albums filled with samples of different shades of ACP and acrylic. This array of choice greatly helps customers arrive at a decision about the kind of signage materials best suited for their particular requirement.

- Rendering a soft copy of the job in 3D: We get two kinds of customers at our place:

- Architects and interior designers who get the job done from us and bill their clients in turn. These designers and contractors generally have a clear idea of what their clients need and are pretty clear about their material specifications.

- Quite often, the end users directly get in touch with us. Obviously one cannot expect them to be experts in the field of architecture and design. End users do need a little bit of hand holding. I feel that it always pays to give them some bit of guidance and consultation with respect to an acrylic light board project.

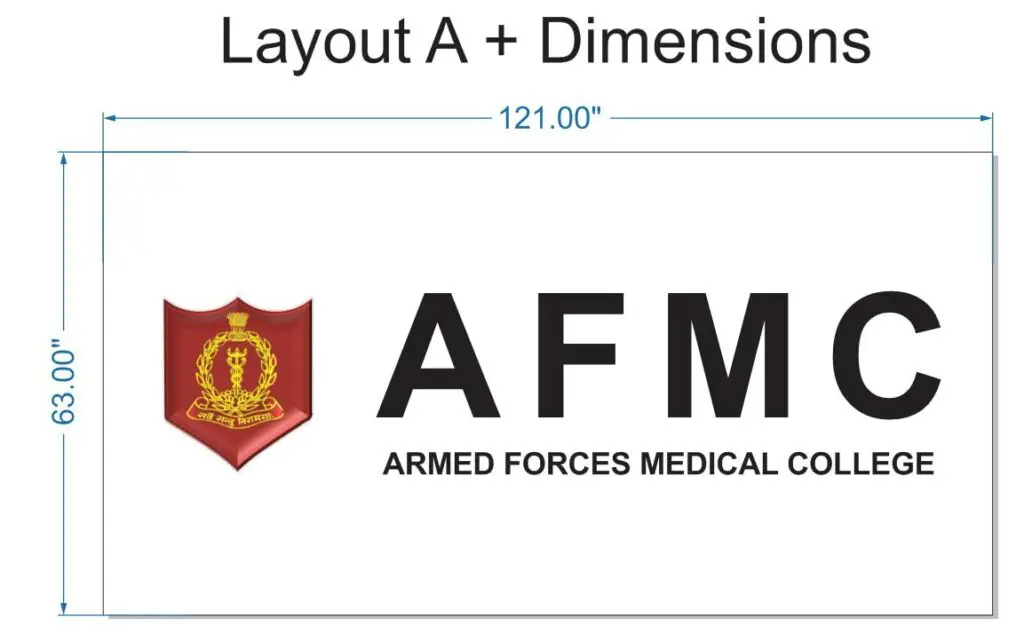

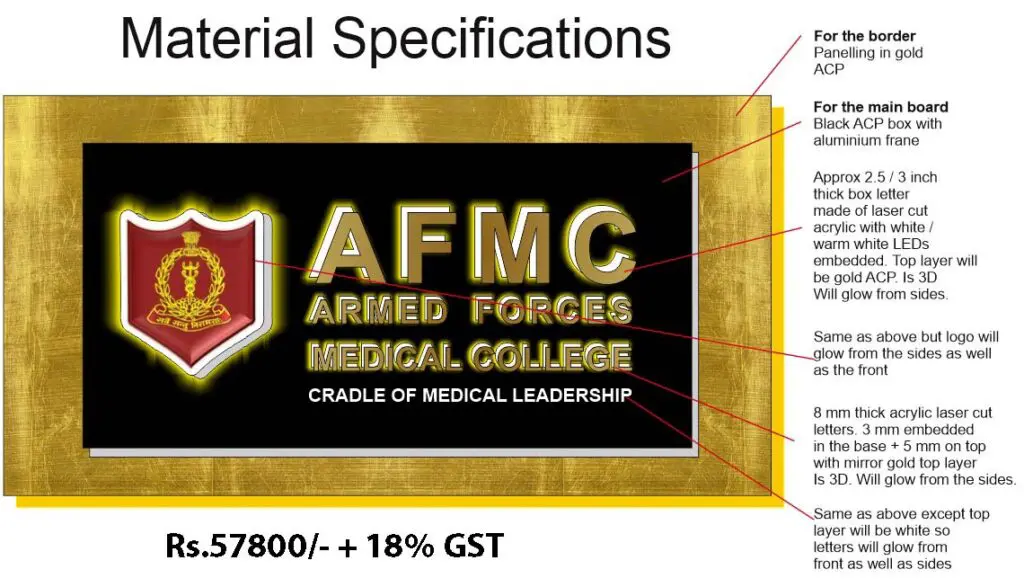

It is extremely important to give the client (be it a middle man or an end user), a preview of what the final job will look like. To this end we create a soft copy render of the signage in 3D. This proposal includes the dimensions, materials that will be used, elements that will be lit / non lit etc.

This transparency on our part helps in a number of ways. With a clear picture of what is involved, the customer can easily evaluate our proposal with that of our competitors and make an informed decision. Secondly, with the specifications clearly mentioned, chances of misunderstanding are greatly reduced. This helps in avoiding any rude surprises at a later stage when the actual job is finished and installed.

FAQs | Frequently Asked Questions

Cost of LED Acrylic ACP Backlit Signs

As we’ve mentioned above, there is no standard parameter (like rate per square foot) that can be blindly quoted for an LED acrylic sign board job. Commodities have fixed rate cards. But a signboard project differs from customer to customer. The cost of any sign board job is determined by a combination of different parameters like –

- The materials that go into making a board

- The dimensions

- The specifications

- Even the number of LEDs used

All these parameters vary from job to job. Further the site where the installation has to take place also influences the final cost.

Each of these factors have to be taken into account before we can give you a meaningful cost for your backlit board job. So if you need to budget for a backlit sign board job, do drop us a mail on [email protected] containing the following details:

- Please attach the artwork / design of the elements that need to go on your shop signs. This could be your company name and logo, its tagline, the fonts associated with the same, etc. Do try to share the high resolution original art file in CorelDraw, Adobe Illustrator format, eps.

- Mention the dimensions you have in mind for the job. Estimated values will work fine and the measurements need not be exact at this stage. We just need to get an idea of the scope of the job involved.

- Do share an image of the site where the installation has to take place along with the address of the same. If the job has to be installed at a very high place or difficult to access location, we might have to send a separate scaffolding team to assess the site.

Follow the Example Below, to Arrive at a Rough Estimate of your Sign Board Cost

You may be at just an initial stage of planning and budgeting for your ACP acrylic board. We understand that you may prefer not to get in touch with us at this stage but are looking for just a rough estimate of the costs involved. In this case, let me share a couple of thumb rules to help you with your budgeting.

A quick disclaimer first: This method involves crude back of the envelope calculations. The actual figure may vary from a properly assessed quote from our end. Nevertheless a ballpark figure may help you in taking a call regarding the signage project.

A sign board has two main components; the base ACP frame and the individual acrylic letters / logos that go on top of the same. The cost of the base ACP frame is Rs.250.00 per square foot. The cost of the individual acrylic letters is to be calculated at Rs.280.00 per running inch on the longer side of the letter. Sounds confusing right? Let me try to make the above paragraph more clear with the help of an illustration.

Let us assume that we need to make a shop board of size 8 feet width X 4 feet height. This frame has to be made out of ACP. Further the letters “HELLO” are to be fabricated out of acrylic and installed on top of the base ACP frame. Each of the letters (comprising the word “HELLO”) has a width of 14 inches and height of 20 inches, except for the letter ‘O’ which has a width of 24 inches. Now the way to estimate the cost of this board would be:

3D Acrylic LED ACP Glow Sign Boards

₹1200.00/Sq. Foot*

Extremely attractive 3D Acrylic LED glow sign boards for your store front

Example Costing:

₹28800.00 for print size of 4 feet X 6 feet (24 square feet X ₹1200.00 per foot)

Please Note:

- The method illustrated above will give you only a rough estimate for your LED acrylic signage. The final figure will vary.

- Do get in touch with us for an exact costing

- 18% GST to be added to the above cost

- Delivery and installation is restricted to Pune City and its surrounding areas

Get a Quote for Acrylic Glow Sign Boards

Please leave us your details and we will respond promptly

Similar Products

Previous Next Acrylic Name Plates To Showcase Your Brand Flaunt…

Shop Boards Printed on Flex with a Metal-Frame

Flex sign boards with prints mounted on a metal frame….

Restaurant menu printing on non-tearable & waterproof pages. New-age thick…