Laser Engraving and Cutting

A New-age Way to Process Wood, Acrylic, Paper, MDF, Rubber Etc.

- Computerized laser engraving to replace traditional acid etching methods

- High accuracy in generating intricate artwork by using tightly-focused laser beam

- Process thin material and flimsy material like paper, metal foils, plastic sheets, etc

- Cut rigid materials like MDF, Acrylic, Balsa Wood, etc

- Ideal for name-plates, tool-traced jigs, machine plates, fancy invites, architectural models, etc.

- Rate starting at ₹ 10 per minute of laser machine time

Share

Everything about Laser Engraving and Cutting

Laser cutting on the other hand is when we use the same laser beam at a much higher power to cut the object through and through.

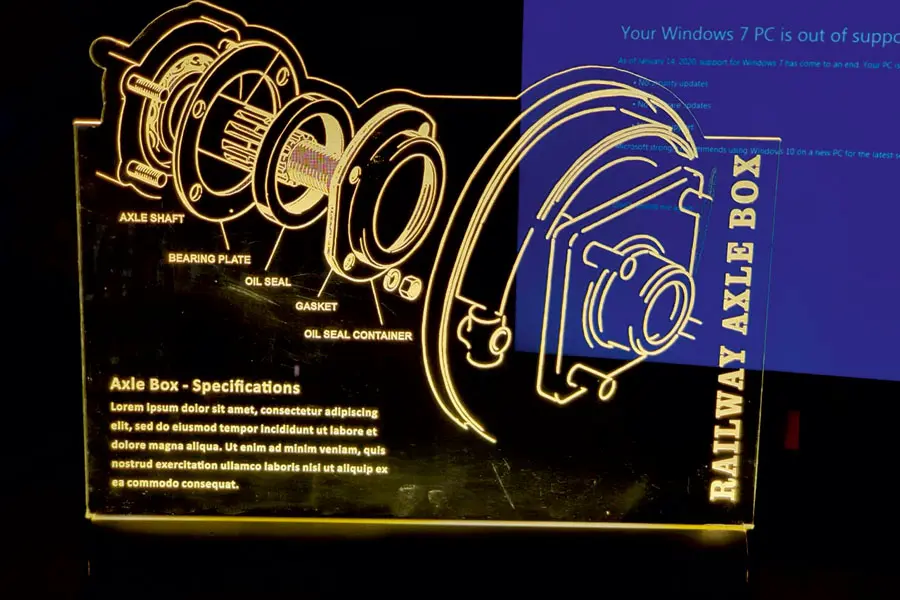

Laser engraving is a process where we use a tightly focused laser beam to etch a design on the surface of an object. This is also known as laser etching.

What is Laser Engraving or Laser Etching?

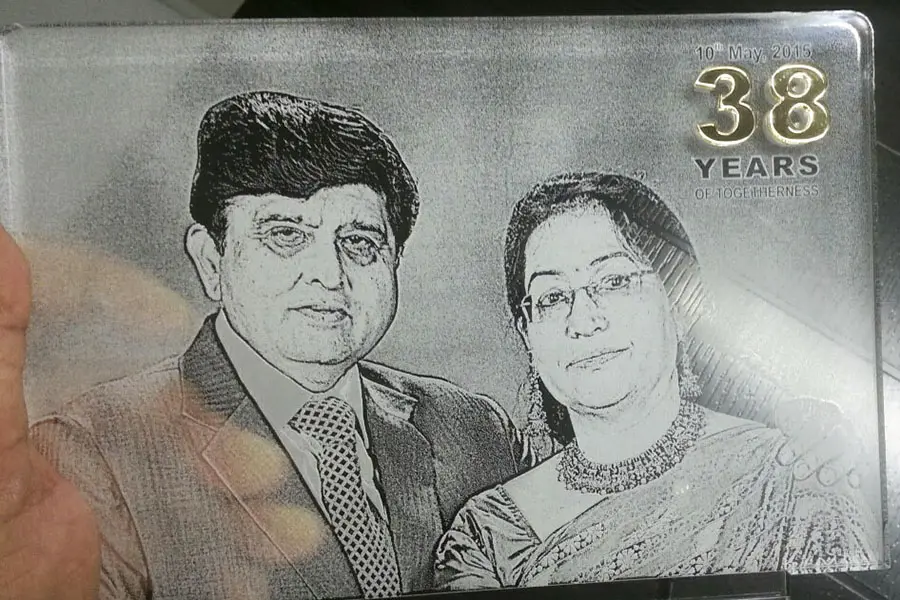

Think of a polished block of wood. When we fire a laser on it, we are essentially scratching its surface. This scratch could be superficial, removing only the polish on the top or a deeper gouge eating into the wood. Either ways, like with any scratch, a different color appears from beneath the surface.

Let us further assume that the block we just used is a white pine and the polish on top is of a dark brown color. Our laser scratch is going to appear white and in strong contrast to the surrounding brown paint. Now if the laser was fired in the shape of a logo or along the lines of a beautiful font to recreate a person’s name, we get a beautiful laser etched design on our object.

Unlike traditional printing methods, laser etching does not use inks or color to do its job. The process burns or engraves designs on various materials. The laser engraved effect looks extremely beautiful on wood, leather, cloth, plastics and even certain types of metals.

What is Laser Cutting?

Laser cutting, as the term states, uses a laser to cut through different materials. We generally think of scissors or guillotine blades (like the photo slitters you see in stationery shops) or even die punches*, whenever we need to cut something. But these traditional tools just cannot cut very intricate designs. They might work for simple geometrical shapes like circles and polygons, but there is no way they can cut a curved font like this:

Happy New Year

Enter, laser cutting services and machines.

At Orchid Digitals, we upload complex designs like floral patterns, CAD designs of machines, etc. and we use our two high powered laser cutters to get the job done.

In case you are wondering, both these functions of laser engraving and laser cutting are performed by the same machine. The difference is in the degree or power of the laser that is deployed. More details on this can be found here.

* Die punching is where you first create a metal die in the shape that you need to cut out. You then push this metal die into the material to punch out the desired shape. Our everyday file punch is a perfect example of the die cutting process. We have 2 cylindrical tubes fixed at a set distance in the file punch. You press the punch through a sheet of papers to get the desired shape (round holes of 6 mm diameter in this case, set at a distance of 80 mm from each other).

As you no doubt figured out, creating dies is a time consuming and costly process. It only makes sense to fabricate a die when you need to punch out vast quantities (say thousands of the same design from a material).

What Materials Can Be Laser Cut or Laser Engraved

Laser engraving can be done on just about any material that you can think of. Laser cutting too is possible with a whole lot of materials (with metal sheets as an exception). Here’s a comparison of materials in terms of the process being applied.

| Materials that have to be processed | Is laser engraving / etching possible on this material? | Is laser cutting possible on this material? |

|---|---|---|

| MDF – Medium Density Fiberboard | Yes | Yes |

| Acrylic | Yes | Yes |

| Cloth Fabric | Thick cloth preferred as thin material will burn through and through | Both thick and thin fabrics can be cut |

| Paper | Paper – thick card stock preferred as thin material will burn through and through | Paper – both thick and thin paper sheets can be cut |

| Wood | Yes wood can be easily engraved and very beautiful effects can be achieved Wood / MDF sheets upto 10 – 12 mm can be cut on laser machines. | Trying to cut wood more than a certain thickness needs a lot of laser power. The problem is, when we shoot a laser at high power on wood for longer periods, the material catches fire! Hence we restrict the thickness of the wood for cutting purposes. |

| Thin metallic foil, metallic sheets of paper or metal plated plastic | Yes. But please bring a small sample to check how the job turns out. | Yes. But please bring a small sample to check how the job turns out. |

| Laser ply / Laser engraving metallic sheets: This is a black plastic sheet with a beautiful metallic gold, silver or copper finish on top. It is widely used in the signage industry and for creating name plates | Yes. Laser ply can be engraved. We also stock some sheets of this material. Please check availability of the same before dropping in at our place. | Yes. Laser ply can be cut. We also stock some sheets of this material. Please check availability of the same before dropping in at our place. |

| Soft stones like marble used as paper weight for gifting purposes | Yes. Can be engraved. But results vary from material to material. Please run a sample job first. | Stone cannot be laser cut |

| Veneer – This is a thin sheet of very premium wood. It comes in a variety of textures. People use it for high end visiting cards | Polished veneer can be engraved and will look beautiful | Cutting veneer into different shapes is also possible |

As mentioned above, you can laser cut or engrave just about any material that you can think of.

People also bring in various objects like visiting card holders, key chains, pen stands, cups, machine panels, etc. for processing. Due to the very wide possibilities that laser engraving service opens up, there is no way we can predict or stock standard materials.

So at our laser cutting and routing division, the customer brings in the material or object that needs to be processed. We do stock stencil material, some types of standard acrylic and MDF.

Do give us a call before planning a job, to check if the material is readily available with us.

What Are the Various Applications of Laser Engraving and Cutting

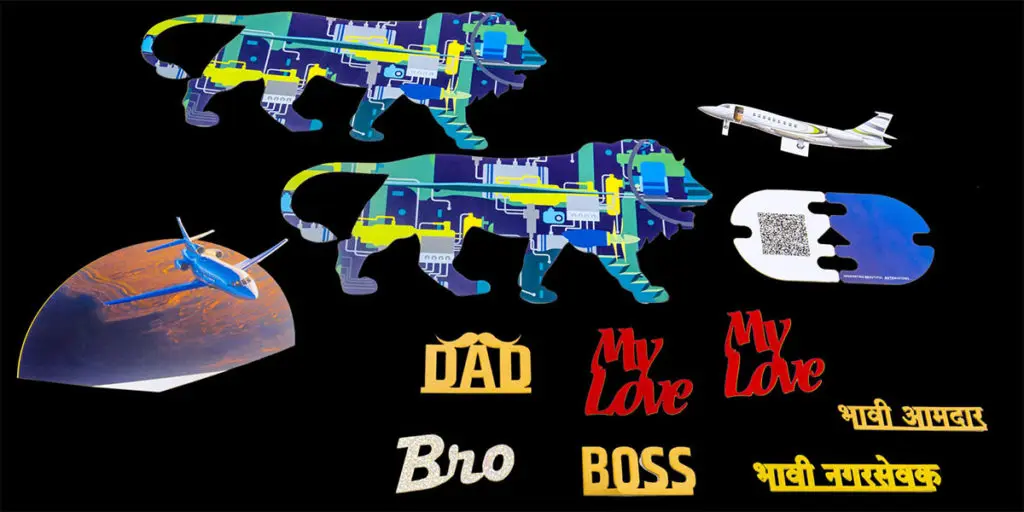

Just about any material can be laser cut or engraved. And our customers are extremely creative with the end applications as well. We have seen people process jaali patterns, birthday cake tags, akash kandil (sky lanterns used in Diwali and Christmas), models planes and buildings, embroidery patterns, lace for cushion covers and curtains, personalised rakhees, labels, number plates, name plates, stands for delicate jewellery like necklaces, etc.

Here is a pretty exhaustive (but not comprehensive) list of applications of the laser cutting and laser engraving industry:

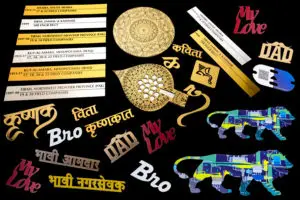

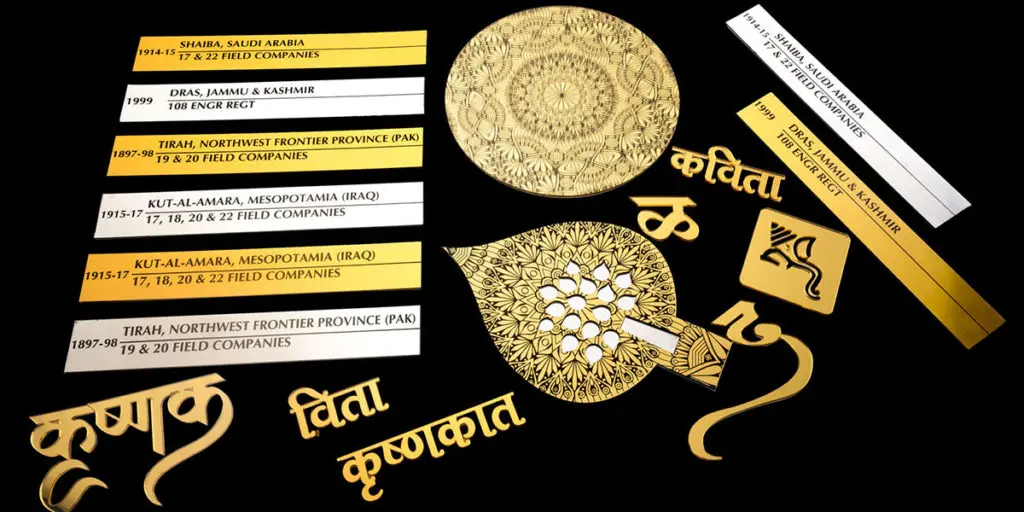

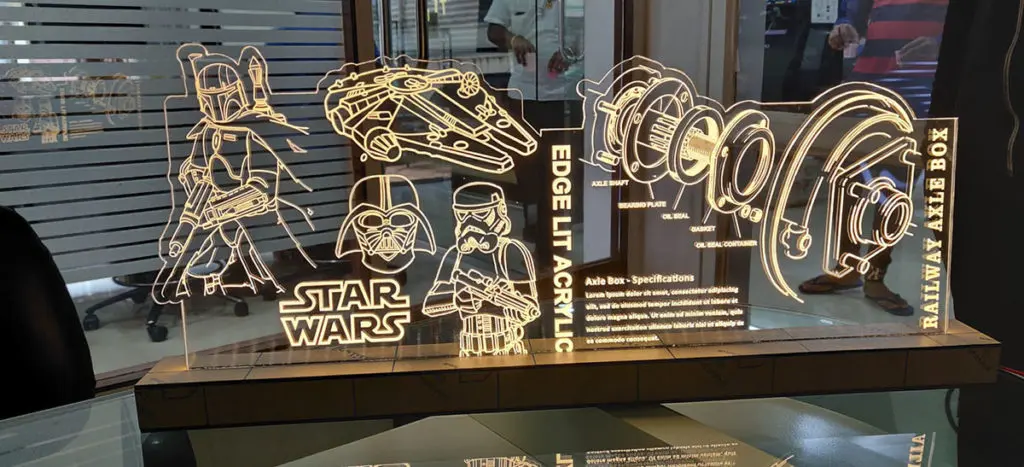

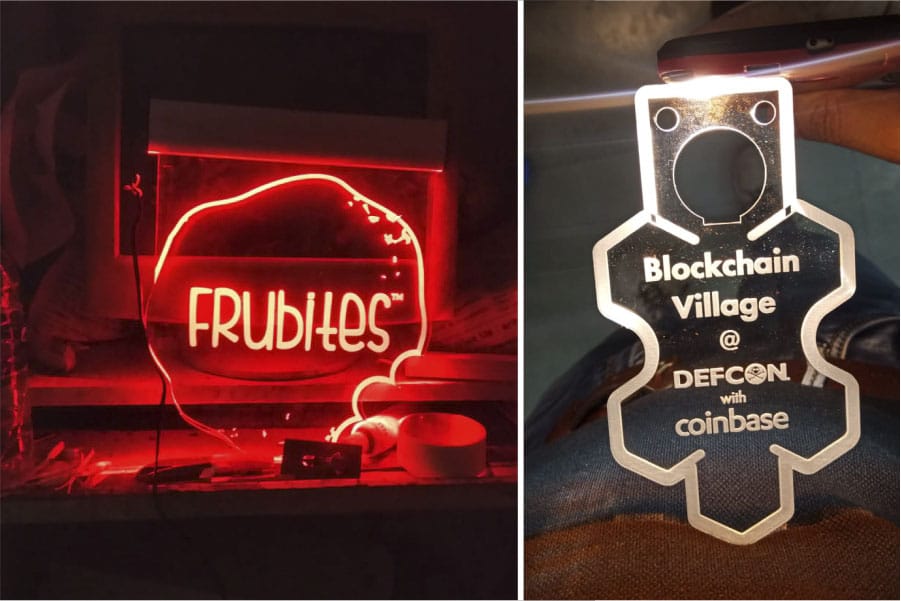

- Acrylic letters and logos for the signage industry: Acrylic is very beautiful glass like material. We use it extensively to fabricate logos and letters for sign boards. Laser cutting machines can output acrylic signs in precise sizes and a very premium, rich-looking finish.

- Tool trays and tool organisers: Engineering companies typically use a lot of tools, each of different sizes and shapes. They laser cut a material called EVA foam (a very high density sponge like material) in the shape of their tools. This laser cut jig works as a perfect tray for storing and packing their tools.

- Jigs for manufacturing and printing shops: Jigs are similar patterns laser cut multiple times in material like paper, acrylic or MDF. Jigs enable processing multiple processing of the same product. An idli tray holding batter for a dozen idlis would be an example of a jig.

Screen printers typically require jigs to print on objects like visiting card holders and wallets. And if the jobs runs into thousands of pieces, a jig holding the wallets in place while being printed upon, makes life easy for them. Engineering companies too, get a lot of these jigs laser cut from us.

- Fancy paper invitations: Premium wedding invitations have very fancy floral designs cut into them. Some of them also have outlines of Gods or the names of the couple cut on the front page. These designs are very intricate and laser cutting is the only way such wedding invites can be created.

- Jaali / designs cut in MDF: MDF and metallic finish acrylic sheets are extensively used for ‘jaali’ patterns. While small jaalis are used for premium invites and packaging, large jaalis are extensively used in interior design and furniture applications. Again, the intricate vector patterns of jaalis can only be reproduced by employing a laser cutting machine’s service.

- Engraving names or logos on a variety of objects like pens, key chains, diaries, wooden stands, etc.: All of us have come across personalised gifts like pens or key chains bearing the recipient’s name. Corporate gifting is a very big business. And we use laser engraving to personalise those gifts with brand names, company logos and peoples’ names.

- Instrument panels: Instrument panels of machines need to be precisely cut to match the sensors and LEDs below. These panels are generally made of a material called polycarbonate sheet. While vast quantities are generally die-punched, small quantities of instrument panels have to be processed on laser cutting machines.

-

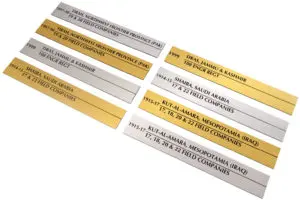

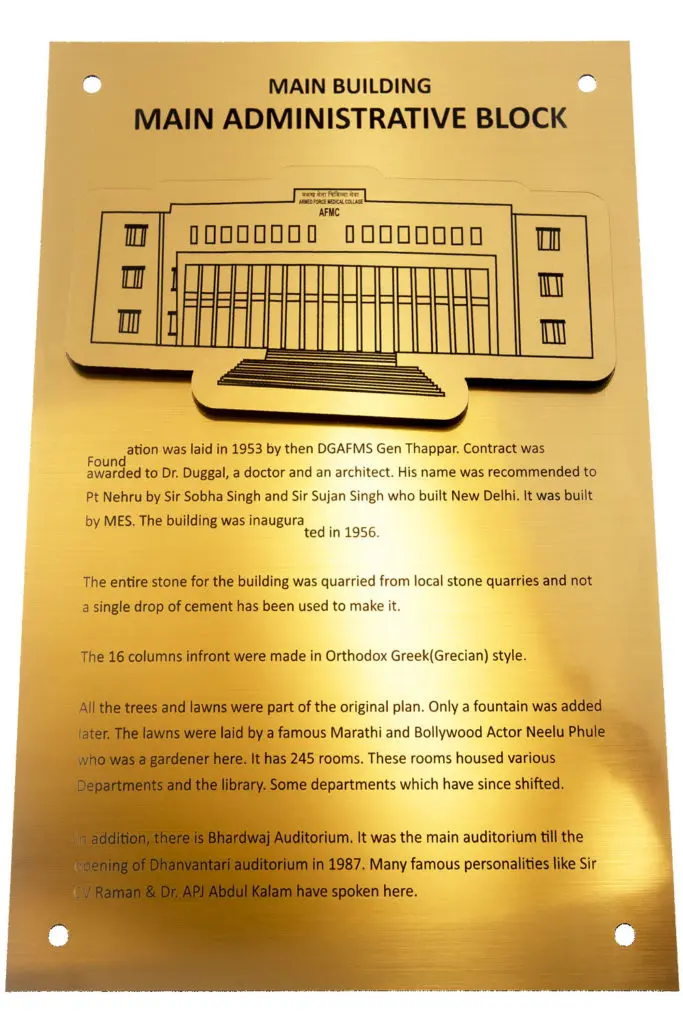

Creating name plates out of golden and silver laser ply: The silver metallic plates that you generally see as direction boards in malls (think of the man / woman icon on doors of the rest rooms) are not really made of metal. We have a material called ‘laser ply’. This is a black sheet of plastic with a metallic coating on top. The metallic finish comes in finishes like silver, gold and copper.

When we laser etch these plates, the top coat burns off to reveal the black plastic beneath. This results in very beautiful and rich looking plates and direction boards. Another every-day item most people can never imagine to be a product of the laser etching service.

-

Fancy name plates: These are almost exclusively made of acrylic, wood, and metallic plates. We use laser engraving to etch names on wood. Individual letters on a nameplate are cut out of acrylic.

While we do not provide this service at Orchid Digitals, it is worth a mention in this list about laser engraving applications.

- Machine plates: Many machine plates are made out of anodised metal. Anodised metal has a coat or layer of color on top of them. So an anodised aluminium plate may have a black colored coat on top. When you laser engrave this plate, the black color gets scratched away to reveal the silver finish of the aluminum plate beneath.

Since aluminium does not corrode and is also pretty sturdy, it is the preferred material for creating long lasting and durable machine plates. Details like machine name, serial number, batch, power requirements, etc. are all etched onto the surface of machine plates.

- Use anodized laser ply / laser sticker for creating labels: Similar to the above application, we also get anodised metallic labels in the market. We can laser engrave text onto these labels which are then pasted onto machine parts

-

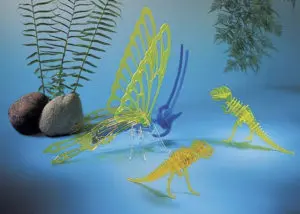

Cardboard models for architects: Interior design students and architects also need to regularly create models of houses. They bring in a high density cardboard which gets cut and creased on our laser cutting machine.

For example, if you need to create a model of a room from a flat sheet of cardboard, the edges, doors and windows get cut through and through. The corners of the walls are etched or half cut. The high density cardboard can now be folded along those edges to create a box like structure representing a room.

-

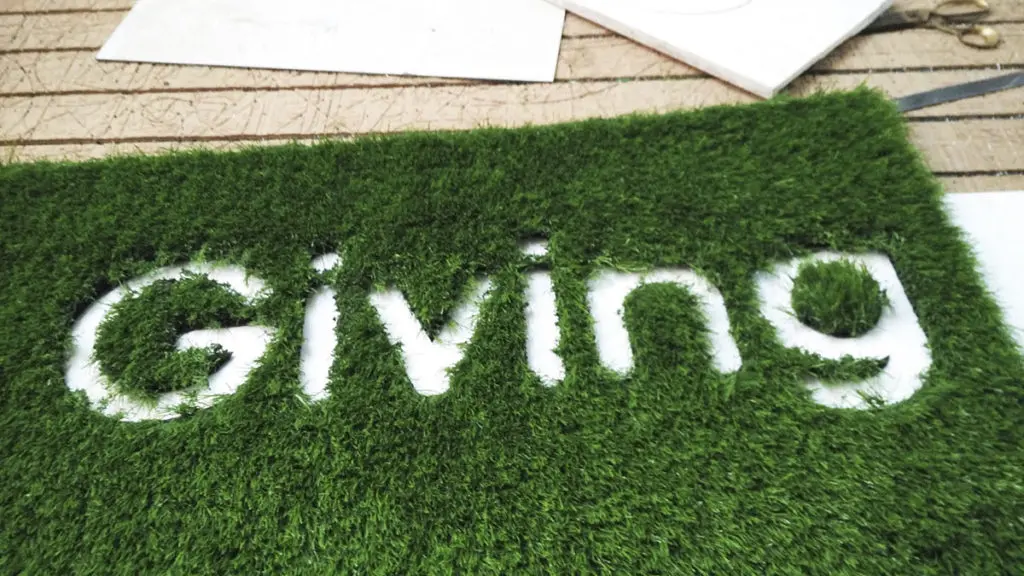

Making stencils out of plastic sheets or acrylic: DIY enthusiasts, painters and engineering firms need to repeatedly paint designs, or patterns. At Orchid Digitals we provide laser cutting service using stencils of thin plastic and thick acrylic sheets. Read more about the same on this page.

-

Fabric cutting for the fashion industry: Students studying fashion designing need to intricate designs on fabric. These laser cut fabrics then go on to make curtain liners, cushion covers, embroidery patterns etc.

-

Craft items: People conducting craft workshops can come up with some pretty original ideas to use laser engraving. They have cut out patterns that can be folded into lanterns, vehicles, even personalised rakhees bearing the names of the brother and sister!

What File Formats Are Needed for Us to Process a Laser Job?

For making the best use of the laser engraving service, we require vector design files. These are line diagrams created by 2D design software like Adobe Illustrator or Corel Draw. We can also work with CAD files.

If you are planning to commission a laser etching or cutting job, it makes sense to understand what kind of file is needed to get the job properly executed. Lasers trace out a path on the objects they are fired upon. This path could be simple geometrical shapes or a very complex design.

Eitherway, this line diagram follows a definite equation to create a defined path. And the laser follows this defined path. Read on to understand the types of files designers create.

Printers typically work with the following two kinds of files:

- Raster / bitmap images:

- Raster files are those which are made up of individual dots or pixels clubbed together

- All photographs and images are raster files. They generally have an extension like, .jpg, .png. and .tiff

- Images in raster files also get pixelated when zoomed in or enlarged.

- So if we try to blow up a small sized image, the print quality can deteriorate

- Raster or bitmap files do not work for laser cutting jobs

- Vector files:

- Work well with laser cutting machines

- They contain line diagrams which follow an equation or mathematical calculation from one point to another.

- The lines and shapes are thus created by joining these points together.

- Lasers get fired in straight or curved lines, and can cut along these shapes

- Images in vector files do not get pixelated when enlarged

Here is a great article that gives more details about these two file types. https://www.geeksforgeeks.org/vector-vs-raster-graphics/

Understanding the Process of Laser Etching and Cutting

Our laser machines are fitted with powerful 100 – 130 watt lasers. The machine has a flat bed on which the objects have to be placed. The laser is fitted on a gantry like mechanism which moves over the bed in both the X and Y directions. The laser beam is triggered (as per the instructions in the design file) when it passes over the object.

Now, we have 2 main parameters that we control while operating the laser machine:

1. The power at which the laser beam is fired: Our laser machines are rated for a max power of 100 – 130 watts. This is enough to cut through an inch thick plank of wood. But the above rating is just the max power that the lasers can be fired at.

We need to vary the power setting based on the material that needs to be cut. In fact we can set our lasers anywhere between a range of 10 watts – 130 watts.

Here’s a quick explanation of why this is necessary.

- A high laser power setting on a delicate material, like silk fabric, might set fire to the same!

- On the other hand, hard materials like a 10 mm thick sheet of acrylic or metal foil are very difficult to cut through. And we need to set the machine at a higher power rating to achieve our desired result.

- Alternatively, a laser fired at a low power might not be enough to get the job done and may even result in ugly burn marks.

- If we fire a 100 watt laser at a sheet of paper, it would instantly catch fire! Thin sheets of plastic burn and start melting. So to process delicate materials the laser power is set at a much lower setting.Wood in case you are wondering, is cut at a power somewhere between paper and acrylic.

2. The speed at which it passes over the object:

- The speed at which the laser passes over the object is the second parameter that we can control. For example,

- If we keep the laser focused over one point on the object, it is bound to cut deep into the same.

- But if we pass the laser quickly over the same object, it will just scratch the surface and give us an engraving effect.

- Let us assume that we want to engrave a design deep into the surface of wood. We keep the power at a medium setting of around 40 watts and reduce the speed at which the laser passes over the wood. Remember, we cannot keep the power too high, else we could end up setting the wood on fire.

For the same job, let us now assume that we do not really need to go too deep with our engraving. So we now increase the speed with which we pass the laser over the object.

While we have a general idea of what speed and power settings are to be used for most materials, sometimes it takes a little bit of trial and error to get laser engraving jobs just right. Hence it makes sense for you to try a couple of samples out first, before placing the final order through our laser cutting and engraving service.

FAQs | Frequently Asked Questions

What Is the Price for Laser Engraving and Laser Cutting Services?

Prices for both laser cutting and laser engraving services are the same. These are, in fact, based on the time it takes to cut or engrave a particular job. For example:

- If the material that needs to be laser cut is very thick, we are going to have to run the laser for a longer period of time to get the job done, than it would take for cutting the job on a thinner material.

- Also, a laser machine will take longer to engrave a more intricate design than a simple design.

Hence the price for cutting or engraving any job is directly proportional to the amount of time it takes to finish that job.

At Orchid Digitals, we charge Rs.10.00 per minute of laser machine time.

To illustrate with an example: if it takes 30 seconds to cut a simple circle on a thick card paper, the cost of that job would be Rs. 5.00 (Rs.10 minute * ½ minute to complete the job).

Let us assume that another job calls for cutting a detailed stencil on the same card sheet. Now the machine takes 15 minutes to finish the cutting. So the cost of the job would be Rs. 150.00 (Rs.10 per minute * 15 minutes to complete the job).

So, unless you actually process the job once, getting an exact cost is difficult.

| Price for Laser cutting or Laser engraving service for a design |

|---|

|

Rs.10/- per minute + 18% GST |

| Time is calculated from the moment the job is actually fired on the machine. Prepress for file setting or machine make ready is not included. |

Please note:

- 18% GST applicable.

Shipping and Delivery

- Laser engraving jobs can be delivered anywhere in India.

- Delivery charges are extra and will be communicated to you once we receive the delivery address.

Get a Quote for Your Laser Engraving and Laser Cutting Job

Please leave us your details and we will respond promptly