Stickers & Labels

A One-Stop Solution for Every Sticker Type Under the Sun

- Order paper labels, shape-plastic / transparent / non-tearable stickers, shape-cut vinyl stickers, 3D embossed decals, night -glow prints, etc.

- We supply digitally printed stickers and labels having an exquisite print quality

- Short-order jobs accepted

- Finishing solutions like lamination and half-cutting for stickers also available

- Prices starting at ₹30 per large sized A3 sheet containing multiple stickers

- Shipping – Across India

Share

Detailed Description

Stickers are fairly ubiquitous in our everyday life. We don’t really give a lot of thought to these small pieces of paper stuck onto products and price tags. But, there is an entire industry devoted to manufacturing labels that impart information, entice customers, and drive sales.

And at the risk of sounding boastful, Orchid Digitals stands at the forefront of this industry.

Imagine: You are a bottler of honey or a manufacturer of homemade snacks / pharaal.

Now, honey is a fairly generic product. And unless you go for a different kind of bottle/container, your bottle is most probably going to end up looking like every other competitor’s bottle.

Placed side by side on a supermarket shelf, there isn’t going to be much to distinguish the two, likewise for the pack of snacks and, in fact, every product packaging.

So, even if your product is superior, you need something to distinguish your offering from everyone else’s. And this is exactly where good packaging, and more specifically, exceptional labels and stickers come in.

Different Types of Stickers & Labels Available

The term ‘Stickers’ is fairly generic.

One can use it to denote a low-end price tag made of paper or premium logo prints made of embossed metal foil. A price tag has just one job to do. That of furnishing information. On the other hand, a logo decal has to enhance the look of the product it is stuck on and give it a premium look and feel.

Stickers are also made from various materials like paper, plastic, metal foil, vinyl, etc.

And if this was not enough, different types of labels have different material characteristics. They can be transparent, opaque, non-tearable, night-reflective, tamper-proof, water-proof, embossed, etc. Heck, we even have stickers that glow in the dark!

In short, when it comes to manufacturing stickers and labels, we have got you covered on various fronts. In fact, we consider ourselves an industry leader when it comes to this product.

Here is a quick list of the different varieties of stickers printed at Orchid Digitals. Click on the relevant section for more details on each individual type.

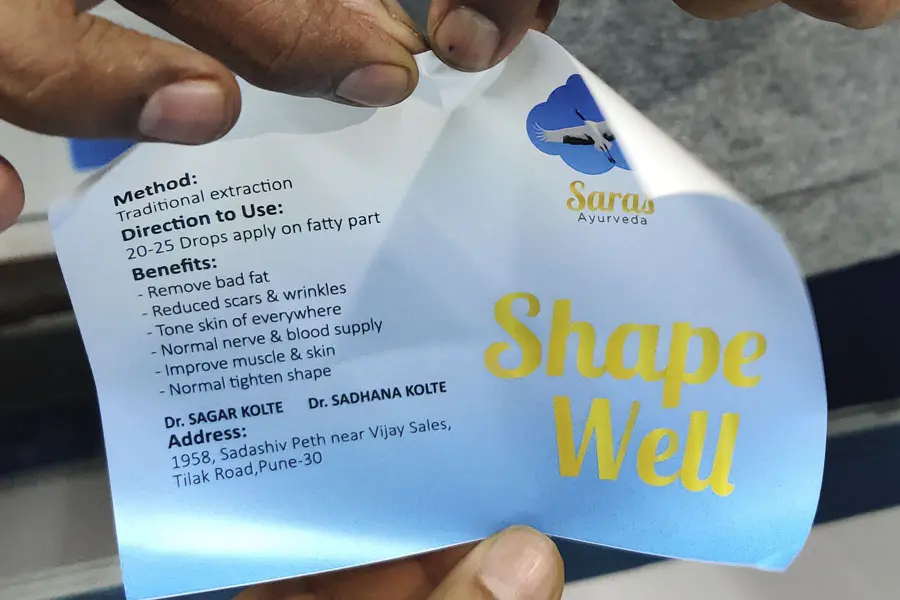

1. Gloss Coated Paper Labels

Regular paper sticker with a very high gloss, mirror finish and strong adhesion. Printed on our color digital press. Ideal for all standard label jobs.

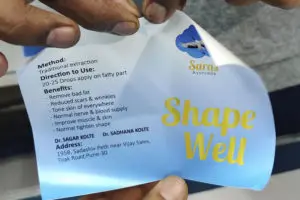

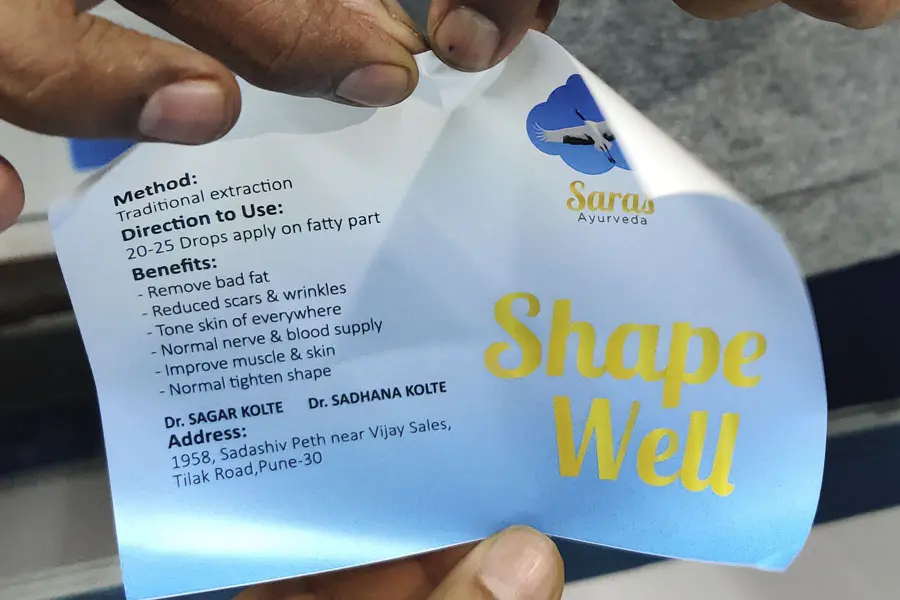

2. Non-Tearable and Water Resistant Plastic Stickers

This sticker is made of plastic, has a matt finish and is waterproof, in addition to being non-tearable. Ideal for products that need to be refrigerated or are exposed to water.

3. Transparent Stickers

As the name suggests, this plastic sticker is transparent and allows you to see the product inside the package. It is a great solution for labelling glass bottles, and transparent plastic pouches.

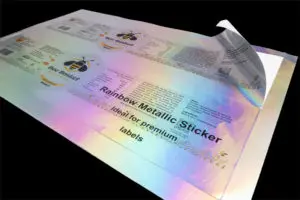

4. Metallised Labels for Premium Products

This metallic foil is used to create premium labels for high-quality goods. We have tints in gold, silver and even bronze finish.

5. Kiss-Cut or Shape-Cut Stickers

Vinyl stickers that can be cut to any shape needed. These labels are UV printed, waterproof and scratch-resistant. Ideal for creating logo decals.

6. UV Coated 3D Raised Effect Stickers

These vinyl stickers have a clear UV coat on top which gives the prints a raised look, and an embossed feel. Premium decals for product branding.

7. Reflective Stickers

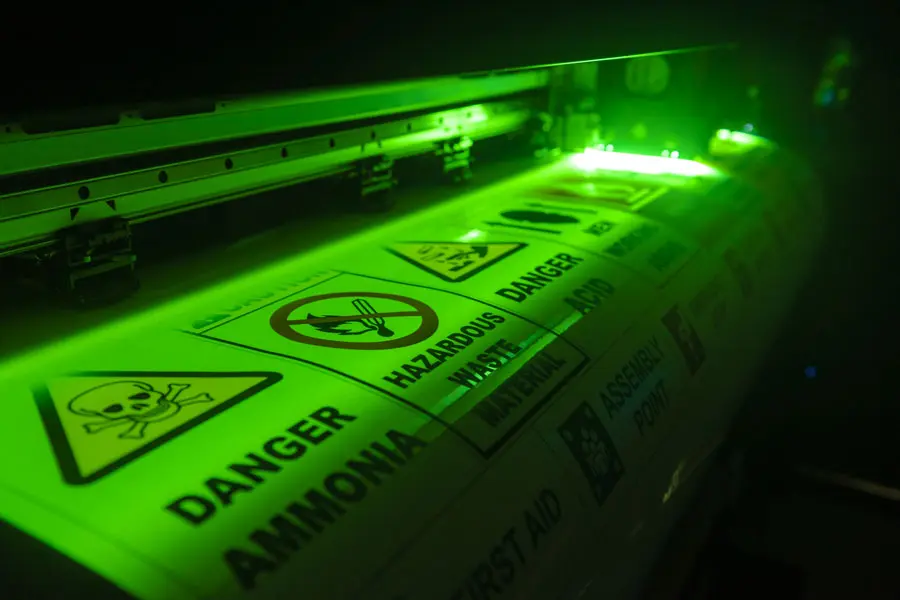

Night reflective stickers have one special quality. They reflect light in the evening and at night. Hence this material is great when it comes to branding vehicles. It is also used for creating road direction signboards.

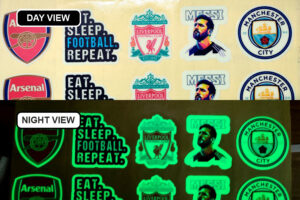

8. Night Glow Stickers

Glow in the dark stickers have a unique property of absorbing light during the day and emitting the same at night (or in total darkness). Ideal for making signs without electricity. Used primarily for creating safety signs in commercial complexes, large buildings and factories.

9. Magnetic Stickers

Magnetic sheet prints are a great idea for creating gifts & memorabilia. Fridge magnets are a huge application of this product.

10. Tamper Proof Labels That Break When They’re Removed

Destructive vinyl labels break apart when someone tries to peel them. This makes them ideal for creating tamper-proof labels, especially in the electronics industry.

11. Extreme Weather, UV Printed, Scratch Resistant Stickers

These stickers are made of a specialised cast vinyl material that has an extremely high tolerance to heat and cold. Further, the stickers are scratch-resistant and waterproof.

12. Reverse Pasting Stickers

This material has glue on the printed surface of the label. This enables pasting from the inside surface of glass partitions. Ideal for car windscreen stickers.

13. Fluorescent Stickers

Fluorescent stickers are available in highly bright and vibrant colours. Use them in places where you really need to grab client attention.

14. Dome Labels

Dome labels have an epoxy resin coat on top which gives them a thick dome-shaped top surface. The stickers have a premium look and feel and are ideal for branding products.

15. Removable Adhesive Stickers

Removable adhesive stickers are a little like post-it notes. You can remove them without spoiling the surface beneath.

1. Gloss Coated Paper Labels

Every corner shop photocopying outlet can provide run-of-the-mill paper stickers. In fact, you can generate these on your home inkjet as well.

But at Orchid Digitals, even when you ask for ordinary paper stickers, you are supplied with a very premium looking gloss-coated print.

Although made of paper, our mirror-cote sticker sheets have a shiny, gleaming finish on top. Further, this print is generated on an extremely high-resolution, color digital press. All of which goes into ensuring four important things for you, as the buyer…

- A Very Low Cost Per Piece: Being made of paper and printed on a digital press keeps the per sticker cost to a bare minimum. You can print thousands of labels without affecting your bottom line.

- High Print Quality: Digital colour prints are light years ahead of any other printing technology, be it offset or screen. So your digitally printed sticker will have extremely vibrant colours, very high resolutions and accurate image reproduction.

- Premium Finish: As mentioned above, the glossy coat makes the print look very high-end and classy

- Strong Adhesion: The mirror-cote sticker sheet has powerful glue. This ensures that the label will not peel off easily.

How Much Does This Paper Sticker Print Cost?

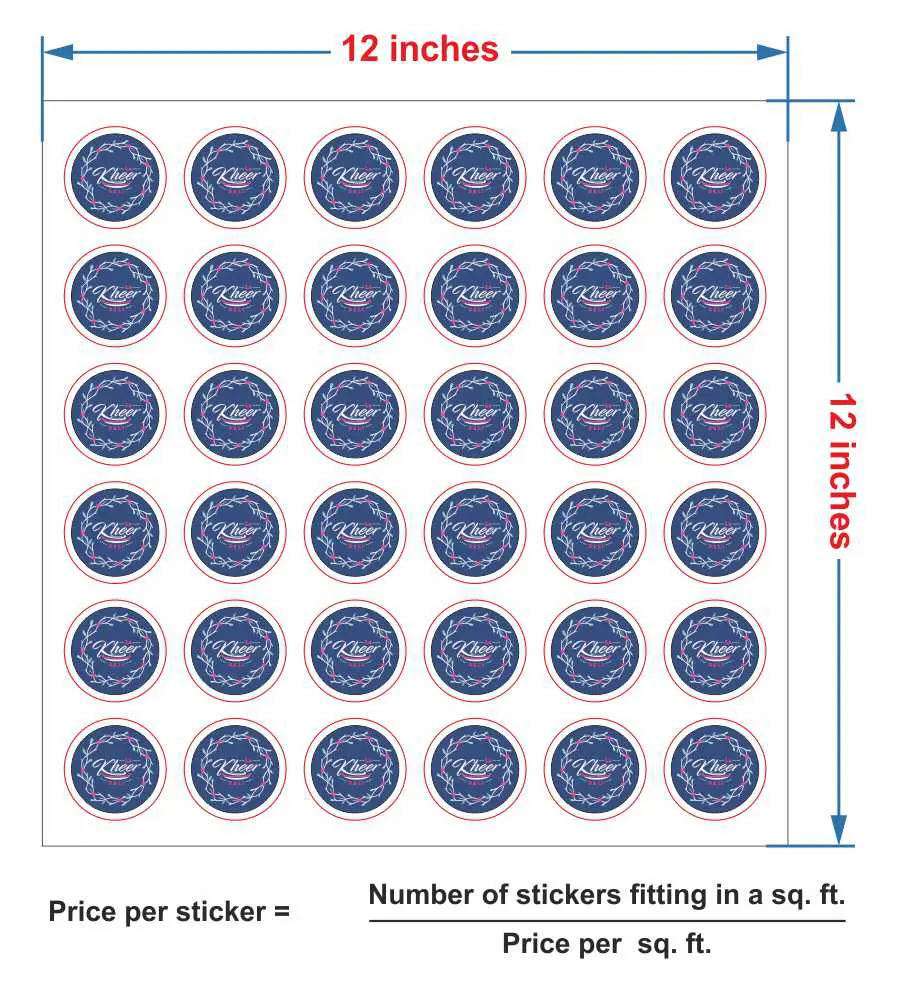

Our paper sticker is printed on a large-sized sheet of 12 inches X 18 inches.

Printing one such sheet costs Rs.30.00 plus taxes.

How to Calculate the Cost of Your Paper Sticker Printing Job?

When you commission a sticker printing job from us, we first lay out as many labels as we can on one A3+ (12 inch X 18 inch) sized sheet. The cost per label is then calculated by dividing the cost per sheet by the number of labels that fit on one sheet.

Here is an example to illustrate the same…

- Cost per single 12 X 18 inch sized, sheet of Mirror-cote, paper sticker = 30.00 + 18% GST

- Number of your labels that fit in a 12 inch X 18-inch area = 20 copies

- So, the cost per label of your size/design = Rs.30.00 / 20 labels per sheet = Rs.1.50 plus 18% GST

Like This Product?

2. Non-Tearable and Water Resistant Plastic Stickers

Paper stickers are great when it comes to print quality. But they are made of paper. And therein lies one problem. They cannot withstand moisture.

Some products need more durable labels that do not easily tear and are water-resistant. Examples of this would be food containers that need to be refrigerated or labels for machines that need to be regularly wiped clean.

In such a use-case, plastic, non-tearable stickers work admirably. This media will not wrinkle or peel off in a moist environment.

It would be best if you opted for non-tearable plastic stickers over their paper counterparts for long term applications like product branding and wet-environment labelling, as these are far more robust.

How Much Do Non-tearable Plastic Stickers Cost?

Non-tearable plastic stickers are printed on a large-sized sheet of 12 inches X 18 inches.

Printing one such sheet costs Rs.40.00 plus taxes.

How to Calculate the Cost of Your Non-tearable Sticker Printing Job?

When you commission a sticker printing job from us, we first lay out as many labels as we can, on one A3+ (12 inch X 18 inch), sized sheet. The cost per label is then calculated by dividing the cost per sheet by the number of labels that fit on one sheet.

Here is an example to illustrate the same…

- Cost per single 12 X 18 inch sized, sheet of non-tearable sticker = 40.00 + 18% GST

- Number of your labels that fit in a 12 inch X 18 inch area = 20 copies

- So, the cost per label of your size/design = Rs.40.00 / 20 labels per sheet = Rs.2.00 plus 18% GST

Like This Product?

3. Transparent Stickers

Non-tearable plastic stickers are water-resistant. But the base media is white and opaque. So, when you paste this print on a package, you cannot see the content within.

Now, there are certain use cases where you need to showcase the product inside the pack while imparting information on the label, all at the same time. And this is where transparent stickers come in.

To understand the utility, let’s go back to our earlier example of the bottle of honey.

Based on its grade, honey comes in different shades, from light golden to dark. The manufacturer might want the colour of the product visible to the end-user.

In this situation, it makes sense to use a transparent label on the bottle instead of an opaque white sticker. Labels for mineral water bottles also fall under this category of stickers.

Transparent stickers, being made of plastic, are also non-tearable and waterproof. And they are far more robust in moist environments than regular paper stickers.

How Much Do Transparent Stickers Cost?

Transparent stickers are printed on a large-sized sheet of 12 inches X 18 inches.

Printing one such sheet costs Rs.40.00 plus taxes.

How to Calculate the Cost of Your Transparent Sticker Printing Job?

When you commission a sticker printing job from us, we first lay out as many labels as we can, on one A3+ (12 inch X 18 inch), sized sheet. The cost per label is then calculated by dividing the cost per sheet by the number of labels that fit on one sheet.

Here is an example to illustrate the same…

- Cost per single 12 X 18 inch sized, sheet of transparent sticker = 40.00 + 18% GST

- Number of your labels that fit in a 12-inch X 18-inch area = 20 copies

- So, the cost per label of your size/design = Rs.40.00 / 20 labels per sheet = Rs.2.00 plus 18% GST

Like This Product?

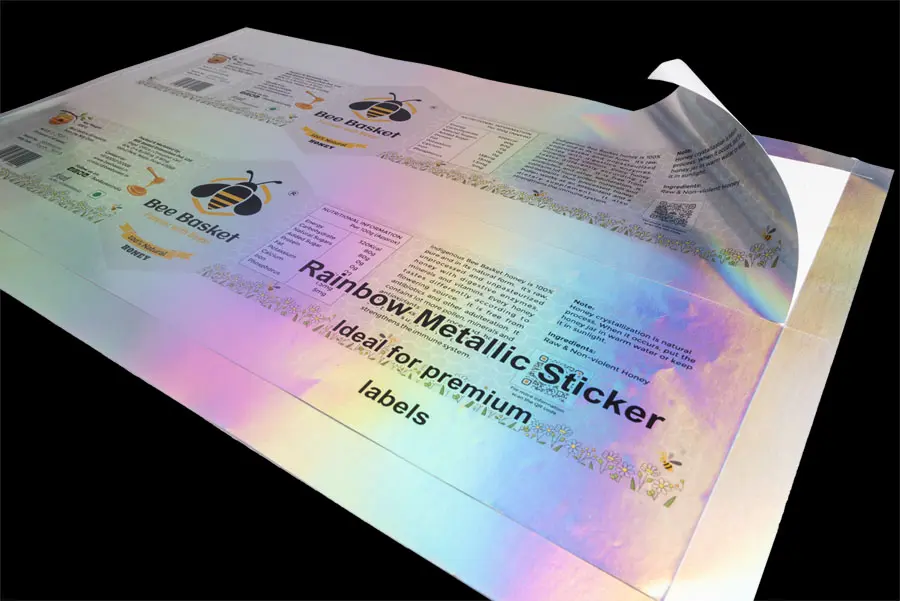

4. Metallised Labels for Premium Products

Metallic stickers are perhaps the richest looking labels in our vast line-up of the same on this page. We have, on offer, sticker sheets in colours like gold, silver and copper. We even stock a rainbow-hued, metallic foil which reflects different colours when viewed from different angles, very much like a hologram label.

Metal finish stickers are more than just a novelty item. Take a look at premium products like cosmetics or deodorants. You’ll observe that the stickers on their bottles are mostly metallised.

A gold or silver brush finish adds an additional dimension to your label. All of which goes on to underline the richness of your product.

At Orchid Digitals, we have both glossy and brush/matte finish metallic sticker sheets to choose from. And as mentioned earlier, you can choose from shades like gold, silver and copper.

How Much Do Metallic Finish Stickers Cost?

Metallic finish stickers are printed on a large-sized sheet of 12 inches X 18 inches.

Printing one such sheet costs Rs.40.00 plus taxes.

How to Calculate the Cost of Your Gold/Silver Sticker Printing Job?

When you commission a sticker printing job from us, we first lay out as many labels as we can, on one A3+ (12 inch X 18 inch), sized sheet. The cost per label is then calculated by dividing the cost per sheet by the number of labels that fit on one sheet.

Here is an example to illustrate the same…

- Cost per single 12 X 18 inch sized, sheet of gold/silver sticker = 40.00 + 18% GST

- Number of your labels that fit in a 12-inch X 18-inch area = 20 copies

- So, cost per label of your size/design = Rs.40.00 / 20 labels per sheet = Rs.2.00 plus 18% GST

Like This Product?

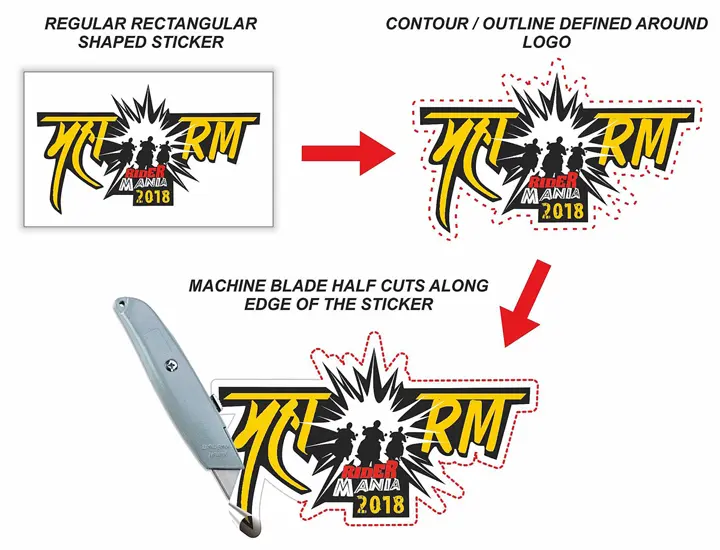

5. Kiss-Cut or Shape-Cut Stickers

Perhaps the most unique kind of print in this list are shape-cut or kiss-cut stickers. And they have got a very catchy name to boot 🙂

Let me explain what kiss-cut stickers are…

Kiss-cut stickers are created by cutting the label in any shape you desire. Printers use a cutting plotter equipped with a very sharp blade. This blade glides/runs over the top surface of a sticker sheet, cutting along the edge of the label as it moves.

As you all know, every sticker is made of two layers.

- The actual sticker media which gets printed upon and has an adhesive backing.

- The release liner beneath. This is the sheet at the base, on which the above sticker sheet rests and gets peeled from by the user.

So, when a shape-cut job is being processed, what is essentially happening is that the sharp point of the blade is essentially ‘kissing’ the top surface of the sticker material without touching (or cutting) the release paper beneath.

And as it glides over the surface, the blade slits or half-cuts the material to make it easy for the end-user to peel the sticker off from the liner beneath.

So what’s so unique about this process? You might wonder.

The thing is, digital printers can program the blade to run in any non-linear shape they desire, with the end result being the ability for you to commission a decal in any shape you want.

The one common thing about all the different sticker varieties listed above is that they are all square or rectangular in shape.

But what if you need a sticker in a custom design and shape, like, say, the shape of your company logo? Or perhaps you prefer a non-linear shape that follows the contours of a cartoon image. Or maybe, even a sticker that is shaped like your product.

Traditionally, the only way to process such jobs was to die-cut them. And you need to print large quantities of stickers to make a die-cutting job economically viable.

But with the kiss-cutting process, you can generate even small quantities of stickers in any shape you desire.

What Kind of Material is Used to Create Shape-Cut Stickers?

At Orchid Digitals, we print your kiss-cutting job on large rolls of vinyl media. These rolls generally have a width of 4/5 feet. Multiple copies of your design are laid out across this width, and the job is then taken up for printing on our wide-format inkjet printer.

We use high-grade UV inks to print out the job on an Avery or 3M brand vinyl. This ensures the following…

- Typically, UV ink prints are of very high quality. These inks also enable print service providers to generate the job at extremely high resolutions.

- UV inks are very robust. The prints are waterproof, scratch-resistant and ideal for both indoor and outdoor applications.

- Moreover, if you couple the above-mentioned inks with high-grade media, your end-product will meet the highest quality standards possible. So we stock vinyl rolls from companies like 3M and Avery. Both of these brands are very popular & of a premium grade. Their printable vinyl rolls are of very high quality, and the media does not degrade easily. The adhesion of the stickers, too, is extremely strong.

To find out more about kiss-cut stickers, check out this detailed product page here.

How Much Do Shape-Cut Stickers Cost?

As mentioned above, shape cut stickers are not produced individually but laid out on a large roll of vinyl media and then processed in a UV printer. The moving blade finally cuts the labels in whatever shape we desire.

Kiss-cut stickers cost Rs.90.00 per square foot plus taxes.

How do you estimate the cost of your sticker printing job? Let me explain with the help of an illustration.

Let us assume that 45 copies of your design fit in an area of 12 X 12 inches (1 square foot). Further, you have a need for 450 individual stickers. So, to generate this amount, you need to print 10 square feet of vinyl. And here is how much it will cost you…

10 sq. ft. X Rs.90.00 per square feet = 900.00 +18% GST for a total of 450 stickers. Or Rs.2.00 plus taxes per sticker print

Like This Product?

6. UV Coated 3D Raised Effect Stickers

Prints images are generally visualised as two-dimensional impressions on a flat sheet of paper. So an embossed print is bound to hold a viewer’s attention. Embossed prints also have a vibrant and premium feel.

Now, traditionally there has always been a problem in commissioning raised-effect, embossed prints. The production process typically involves multiple steps like dies, stamps and punching. This, in turn, increased costs and lead-time in processing an embossing job, which resulted in people shying away from buying this product.

But at Orchid Digitals, we have an inline embosser where the printing and embossing happen simultaneously. We can also couple this with the kiss-cutting process described in the previous section to create raised effect embossed stickers in just about any shape you desire.

This embossed effect adds a tactile feel to logos. Also, it helps highlight certain areas of the print. For example, the eyes or lips of the model may look glossy and raised while the rest of the image is given a matt and subdued finish.

This effect is achieved by a process called spot UV printing. This technology is not widely available at most printing stores. This fills us at Orchid Digitals with even more pride in being able to provide this particular kind of sticker printing service to you.

This product is great when it comes to branding products. A 3D logo sticker pasted on top is just what is needed to personalise costly white goods and even gifts.

You can read more about these 3D Raised Effect stickers here.

How Much Do Embossed, Raised-effect Stickers Cost?

Raised effect stickers are not produced individually, but laid out on a large roll of vinyl media which is then processed in a UV printer. The job is finally cut to shape using the kiss cutting process.

These stickers cost Rs.150.00 per square foot plus 18% GST.

So for example, if 50 copies of your logo/design fit in one square foot (an area of 12 inches X 12 inches) your per piece cost works out to Rs.150.00 / 50 = Rs.3.00 + taxes

Like This Product?

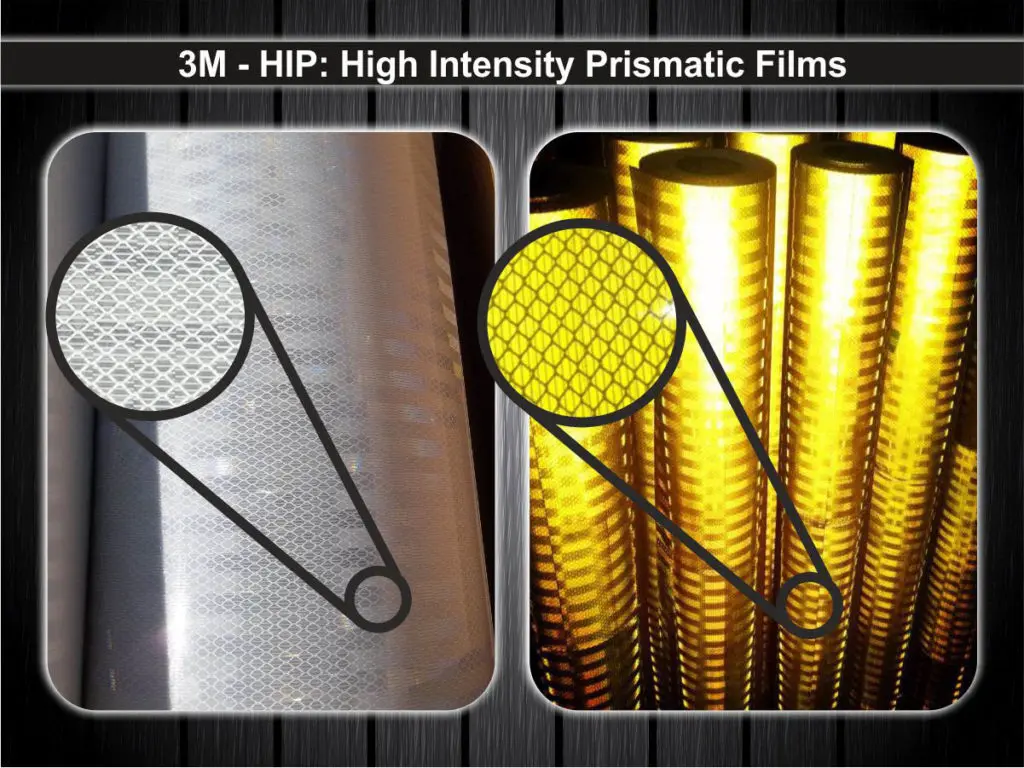

7. Reflective Stickers

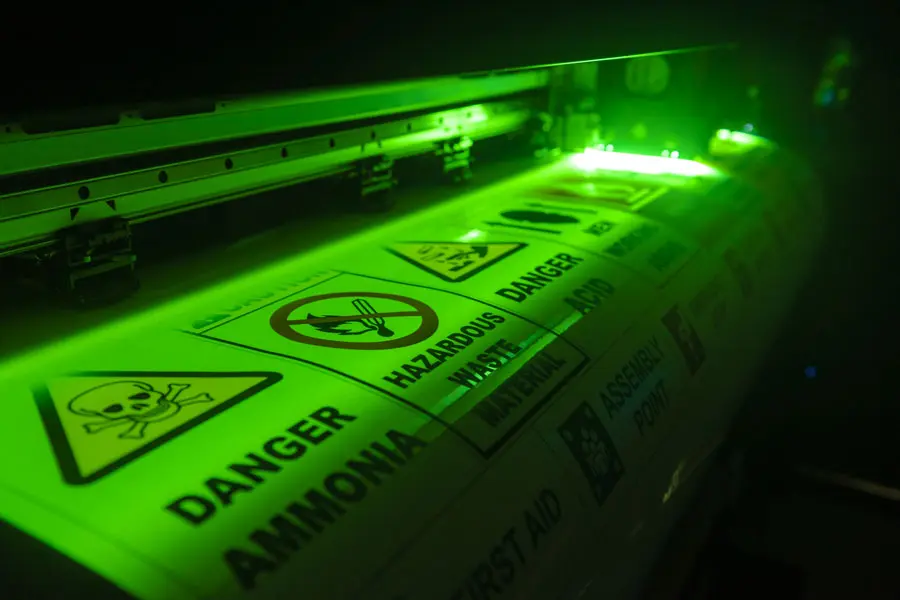

The print industry also serves up a specialised radium reflective material that shines in low light conditions. And you can choose to create night reflective stickers from the same.

Reflective prints are ideal for low-light situations and scenarios where you want your sticker to shine brightly and become visible when light falls on it.

For example, reflective stickers are widely used in creating road direction signs, vehicle decals, and even parking permits for cars and bikes in housing societies.

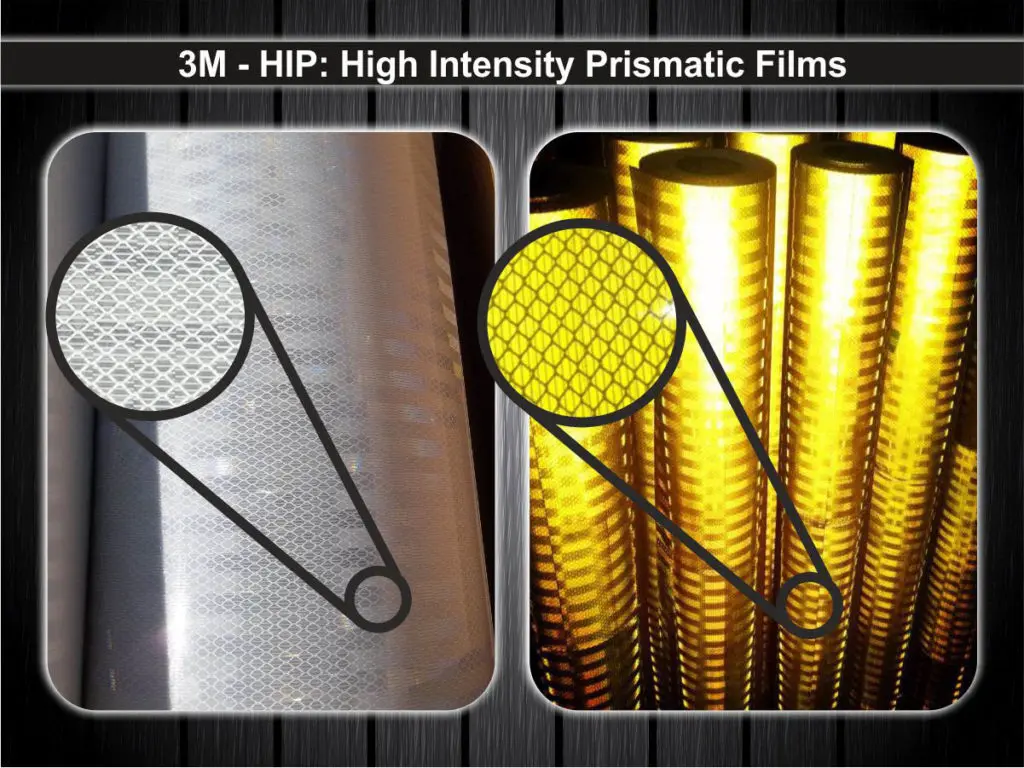

At Orchid Digitals, we stock a very premium, reflective media called – 3M HIP. 3M is a well known American brand specialising in glues and adhesives. Also, HIP stands for High-Intensity Prismatic film.

The above term “HIP” conveys that this sticker media has small prisms or bits of glass embedded under its surface. And these prisms act like tiny mirrors to intensely reflect light and make our print visible in low light conditions.

The USP of reflective prints is that you do not need any electrical power or external light arrangement to make your print readable. For example, you may have noticed the direction boards on the highway and at toll booths.

These signs look pretty ordinary during the day and are easily readable.

But in low light conditions, like in the evening or at night, these signs instantly blaze up when the beams of your car’s headlamps fall on them. Their reflective property makes the prints visible, even from half a kilometre away.

And if you are curious to know more, here is a very detailed product page about night reflective prints.

How Much Do Reflective Sticker Prints Cost?

3M HIP reflective sticker prints cost Rs.220.00 per square foot plus 18% GST.

So for example, if the size of your print job is 4 feet wide X 2 feet high, the total cost is calculated as:

4 feet X 2 feet X Rs.220.00 = Rs.1760.00 + 18% GST

Like This Product?

8. Night Glow Stickers

Nightglow prints, as the name suggests, glow in complete darkness. These prints absorb light during the day and slowly emit the same at night or when darkness falls.

Glow-in-the-dark radium stickers are widely used to create emergency exit signs and fire safety signs.

In the event of a fire, a building’s electrical power/supply is one of the first things that stop functioning. Visibility is reduced. And people trapped in the dark, smoke-filled rooms need help finding the nearest exit.

In the absence of power, an electrically lit sign is of no use. So what is needed are high visibility prints that glow in the dark and do not need electricity to function.

Glow in the dark prints also have a novelty value. Stickers made of this material are often seen stuck on the walls of children’s rooms, acting as a non-powered night light.

Here is a very detailed product page about night glow sticker prints if you are curious to know more.

How Much Do Night Glow Prints Cost?

Glow in the dark, sticker prints cost Rs.180.00 per square foot plus 18% GST.

So for example, if the size of your print job is 4 feet wide X 2 feet high, the total cost is calculated as:

4 feet X 2 feet X Rs.180.00 = Rs.1440.00 + 18% GST

Like This Product?

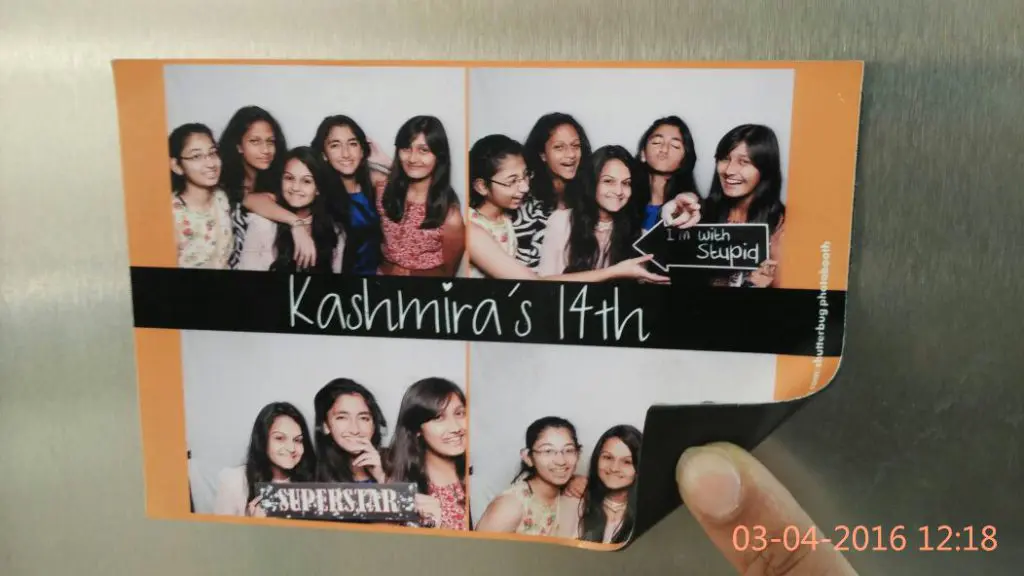

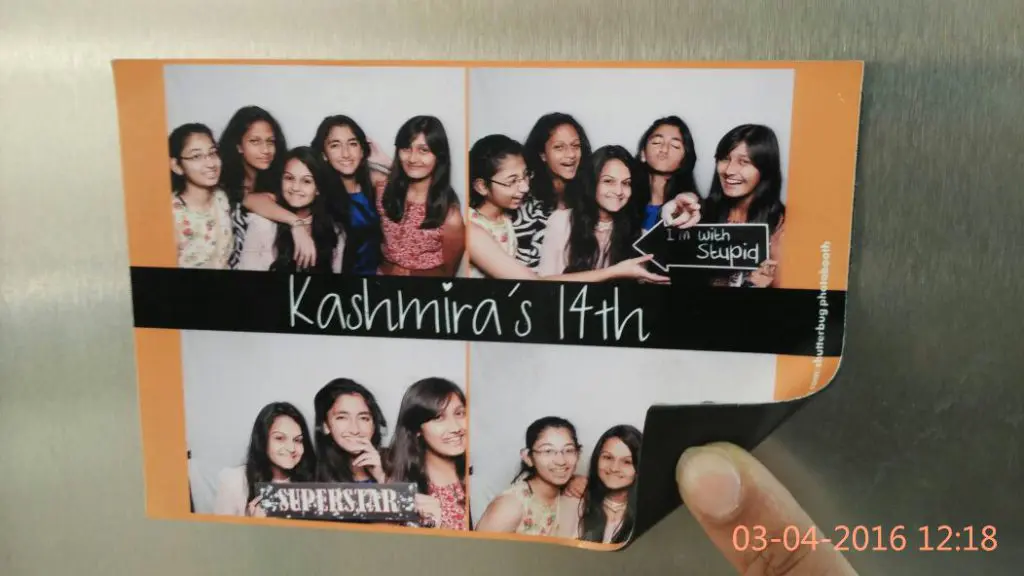

9. Magnetic Stickers

Prints on magnets are not self-adhesive labels in the sense that they do not use glue. But they work admirably by sticking on metallic surfaces. And hence this product is included in this list of sticker options.

At Orchid Digitals, we create custom printed magnets using a material called ‘Plasto ferrite’ magnet sheets.

As the name suggests, this sheet is made of a thin sheet of magnetised iron, sandwiched between two layers of plastic. One side of this sheet is printable. The other side is magnetised and adheres to any iron surface.

Magnetic signs and fridge magnets are a prime application of this type of magnetic stickers.

We have an entire product page devoted to our magnetic stickers solutions that you can learn about by clicking here.

How Much Do Magnetic Prints Cost?

Magnetic sticker prints cost Rs.450.00 per square foot plus 18% GST.

So for example, if the size of your fridge magnet is 2 inches wide X 3 inches tall, 24 such copies will fit in one square foot (an area of 12 inches X 12 inches).

And the cost per piece can be calculated as:

Rs.450 / 24 copies = Rs.18.75 + 18% GST per fridge magnet

Like This Product?

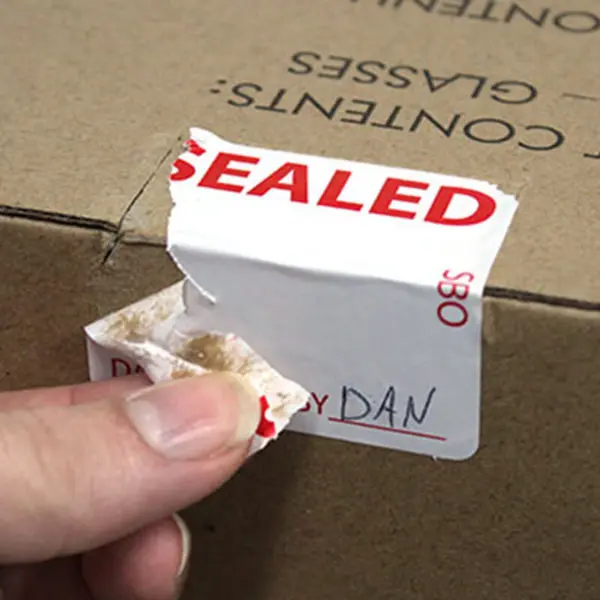

10. Tamper Proof Labels That Break When They’re Removed

Everyone’s familiar with the ‘Warranty Void if Seal Tampered’ label on consumer goods.

The speciality of this label is that it breaks/cracks into small parts if someone tries to peel it. And this cracking of the media makes it impossible to peel the whole sticker and then repaste it later.

This acts as a giveaway and ensures that the product has not been tampered with. The industry name for this security product is destructible vinyl labels.

At Orchid Digitals, we use specialised destructive vinyl media to create such labels for the electronics and consumer goods industry.

Like This Product?

11. Extreme Weather, UV Printed, Scratch Resistant Stickers

There are certain use case scenarios where we need highly robust stickers that can withstand extreme weather conditions. For example:

- Labels on an oil pipeline need to withstand freezing cold, as well as hot desert-like conditions.

- Instruction stickers for construction rigs that stand in the open all day long.

- Stickers for heavy machinery on a shop floor that withstand constant wear and tear from dust, oils, grease and water.

- Another example would be a sticker on a solar panel that will almost continuously be exposed to harsh sunlight and may lead to cracking and fading of the inks on top.

To be able to meet these extreme working conditions, we need a sticker that has two properties:

- A base media that has a very high tolerance for both hot and cold temperatures. Such media should not crack or peel even when exposed for a long time in these extreme weather conditions.

- Printing inks that will not fade or rub off in even the harshest conditions, as shown in the examples above.

To meet these conditions, we stock specialised, branded rolls of vinyls at Orchid Digitals.

One such example is the 3M IJ 180 C brand of vinyl media. According to the spec sheet on the 3M website, this particular material has a temperature tolerance of -60°C to +107°C. And it has a max durability of 7 long years!

In industry parlance, these high-grade vinyl rolls are also referred to as ‘cast vinyls’.

In addition to using cast vinyl, we also deploy cutting-edge UV inks to print jobs that need to survive harsh weather conditions.

UV inks are among the hardiest in a digital printer’s arsenal. Not only are UV printed stickers waterproof and heat resistant, but they are robust enough to withstand very high levels of abrasion and scuffing.

In fact, UV inks are so strong that they are even used to create floor stickers for malls and retail shops. These stickers do not spoil even when hundreds of customers walk on top of them.

So, if the surface where the sticker has to be applied is going to be continually handled, wiped or washed, UV inks can easily rise up, to meet this challenge.

A judicious combination of high-grade cast vinyl and UV inks will result in a print that is weather-proof, waterproof scratch-resistant and heat-resistant.

Cast vinyl stickers have one additional property. They have a very strong adhesion which makes them extremely long-lasting and difficult to peel. So, for example, if you need to brand a vehicle for a more or less permanent basis, you would opt for this media.

How Much Do Cast Vinyl Prints Cost?

UV ink prints on cast vinyl cost Rs.180.00 per square foot plus 18% GST.

So for example, if the size of your print job is 4 feet wide X 2 feet high, the total cost is calculated as:

4 feet X 2 feet X Rs.180.00 = Rs.1440.00 + 18% GST

Like This Product?

12. Reverse Pasting Stickers

When people think of self-adhesive labels, they automatically visualise a printed sheet with glue beneath the same for pasting. And this is true 99% of the time.

But when it comes to pasting stickers on transparent surfaces like glass or clear sheets of acrylic, we can also paste the stickers from the inside surface of the glass panel. And in this case, we need the print where the glue is applied on top of the printed image.

‘PUC’ or Pollution Under Control inspection stickers are probably the most common examples of reverse gummed prints. We stick these labels on the inside of the car’s windscreen. Parking permits for four-wheelers are a similar example.

While most stickers have glue on their lower surface, reverse pasting stickers have an adhesive layer on top of the printed, front surface. This allows the parking sticker to be pasted from inside the vehicle cabin, on the inward surface of the glass.

You can read in more detail about parking stickers here.

Reverse pasteable vinyl is also used to brand the windows of high-rise buildings. Accessing a window on the 7th floor of a high-rise (or 17th floor, for that matter) from the outside, may prove to be difficult. You’d probably need a crane to enable the fitters to reach these heights.

So an easier alternative to brand the window would be to paste the sticker from the inside, of the floor, facing outwards.

Using reverse pasting film, we can very easily achieve this.

How Much Do Reverse Pastable Vinyl Stickers Cost?

Reverse pastable vinyl stickers cost Rs.90.00 per square foot plus 18% GST.

So for example, if the size of your print job is 4 feet wide X 2 feet high, the total cost is calculated as:

4 feet X 2 feet X Rs.90.00 = Rs.720.00 + 18% GST

Like This Product?

13. Fluorescent Stickers

Most sticker sheets have a white base, and you print coloured images on top of them. But we also stock fluorescent sticker sheets which are available in extremely vibrant and eye-catching colours.

And anything printed on top of these strongly coloured sheets is sure to catch a consumer’s notice.

All of us have heard of the adjective – bright fluorescent green (or yellow/orange). These bright colours have one agenda – to draw attention to them. So, discount labels or stickers announcing sales are generally printed on these coloured fluorescent sheets.

These sheets are available in size 12 inches X 18 inches and cost Rs.40.00 + 18% GST per sheet to print.

Like This Product?

14. Dome Labels

Product labels and logo stickers, especially for electronic white goods, generally have a raised 3D dome or clear bubble on top. These product stickers are created by pouring a clear epoxy liquid on top of the shape cut vinyl sticker.

You can read more about the dome stickers here.

While this product is no longer made in Orchid Digitals, it’s mentioned here to make this list more inclusive.

15. Removable Adhesive Stickers

Some stickers are like post-it notes and might have to be removed after they’ve served their purpose.

Regular stickers leave behind a layer of glue if someone tries to peel them off. And this makes the surface beneath look very tacky.

RA stickers, short for removable adhesive stickers, leave no residual glue that could spoil the surface of the product upon peeling. This makes them ideal for laptop skins and for personalising mobile phone covers.

Another prime use-case scenario of removable adhesive stickers is when you need to advertise on a vehicle. Prints on buses and rickshaws need to be removed once the ad campaign is over.

In this case, even upon removal, the adhesive on the back of the sticker won’t spoil the vehicle’s paint. Orchid Digitals provides specialized vehicle media prints for such applications.

How Much Do Removable Adhesive Vinyl Stickers Cost?

Removable adhesive vinyl stickers cost Rs.90.00 per square foot plus 18% GST.

So for example, if the size of your print job is 4 feet wide X 2 feet high, the total cost is calculated as:

4 feet X 2 feet X Rs.90.00 = Rs.720.00 + 18% GST

Like This Product?

Different Finishing Options Available After Sticker Printing Is Done

As seen above, stickers get printed on plastic, paper, metal foils, reflective and even night glow media. But in addition to the print, Orchid Digitals also provides quite a few finishing options for your sticker printing job.

For example, you can give a metallic sticker, a gloss, a matt, or even a glitter finish. Alternatively, a client may ask for his prints to be laminated for durability.

So, here is a list of the frequently requested finishing options that you may want to consider for your sticker printing job.

Half-Cutting of Sticker Paper

Half cutting is a process that enables easy peeling of labels, from the underlying release paper.

This process slits the upper layer of the sticker (that bears the print on top and adhesive beneath). The release paper (the lower layer of the sticker), is not cut through, but kept intact. So when you bend the sticker sheet slightly, one corner of the label pops up and makes peeling of the stickers extremely easy.

Stickers are generally printed in multiples on large sheets of size 12 * 18 inches or bigger. Therefore, half-cutting the stickers makes sense as trying to separate the label from the release liner can otherwise be quite aggravating.

Lamination

Some premium products need labels that do not get easily scuffed or scratched. In these scenarios, we laminate the stickers with an additional layer of transparent film.

In addition to increasing the durability of the print, laminating films are also used to give a high-gloss or a silky matt finish to the stickers.

Variable Data Printing

In some situations, the content of each individual sticker may vary.

For example, A job may call for individual address labels to bear the different addresses of the recipients. Alternatively, there might be a case where each sticker might contain different numbers from a sequence.

What we do at Orchid is pull this variable data from a database, place it in a predefined format and print out labels containing different information. This enables us to print stickers having a similar template and layout but different (or variable) information.

FAQs | Frequently Asked Questions

How Much Does Sticker Printing Cost?

As described above, decals could be printed on a single sheet or a huge roll of vinyl. Print houses generally stock sticker sheets in size 12 inches by 18 inches (A3 extra). So the price quoted in the table below is on a per sheet basis having size 12 X 18 inches.

On the other hand, stickers are also generated from huge rolls of vinyl. These printable rolls of plastic have a form factor similar to the huge bales of cloth we see in garment stores. So, for products that are printed on the larger vinyl rolls, the rates are quoted on a per square foot basis. Also, if you are curious to know more about vinyl printing, jump to this post here.

Going by the above explanation on units, here is a price chart for printing different types of stickers

Paper Stickers

₹1500.00/for 50 sheets of A3 Size*

Ideal solution for everyday labelling applications

NT – Non Tearable Plastic Stickers

₹2000.00/for 50 sheets of A3 Size*

Ideal of labelling food products or packs that may be exposed to water

Transparent Plastic Stickers

₹2000.00/for 50 sheets of A3 Size*

Ideal for labelling bottles or containers whose contents need to be viewed by the buyers

Metallic Foil Stickers

₹3000.00/for 50 sheets of A3 Size*

Eye-catching metallic foil stickers to brand premium products

Paper Stickers

₹1800.00/for 30 sheets of A3 Size*

Ideal solution for everyday labelling applications

NT – Non Tearable Plastic Stickers

₹2700.00/for 30 sheets of A3 Size*

Ideal of labelling food products or packs that may be exposed to water

Transparent Plastic Stickers

₹2700.00/for 30 sheets of A3 Size*

Ideal for labelling bottles or containers whose contents need to be viewed by the buyers

Metallic Foil Stickers

₹3600.00/for 30 sheets of A3 Size*

Eye-catching metallic foil stickers to brand premium products

Fridge Magnets

₹2000.00/for 120 pieces of 2 inch X 3 inch sized magnets

Magnetic prints that get fixed to fridge doors and thus remain in the clients view forever

Glow-in-the-dark stickers

₹2400.00/for a sheet of size 3 feet X 4 feet (12 square feet)*

Radium-coated stickers that emit a glow / or shine by themselves at night

Night reflective stickers

₹2700.00/for a sheet of size 3 feet X 4 feet (12 square feet)*

Stickers made from reflective media that shine when light falls on them

Extreme weather vinyl stickers

₹2400.00/for a sheet of size 3 feet X 4 feet (12 square feet)*

Extremely robust and strong prints. Will not degrade in outdoor locations or in extreme weather.

Destructible vinyl prints

₹1440.00/for a sheet of size 3 feet X 4 feet (12 square feet)*

Eggshell labels that instantly disintegrate at any attempt of peeling thus showing evidence of tampering

Reverse pastable stickers

₹1440.00/for a sheet of size 3 feet X 4 feet (12 square feet)*

Prints with glue/adhesive on the front face to enable pasting from the inside of transparent surfaces like glass

Please note:

- The first four items in the list above are available in large size sheets of dimensions 12 inches * 18 inches. Hence, the rate is given per sheet.

- The remaining stickers are available in the form of large rolls of plastic. Hence the rate quoted is per square foot (12 inches wide by 12 inches high).

- 18% GST applicable on the prices mentioned above

Shipping and Delivery

- Stickers are delivered anywhere in India.

- Delivery charges are extra and will be communicated to you once we receive the delivery address.

How to Determine the Cost per Sticker of Your Specific Design?

As mentioned above, sticker prices are generally quoted per area of the material, either as a square foot or as a sheet of size 12*18 inches. But both these areas are most probably larger than your small sized sticker.

So how do you figure out the per piece cost of your individual label?

This process involves a little bit of reverse calculation. What we need to do is, figure out how many individual pieces labels fit in an area of 12 inches * 12 inches.

Let’s suppose that we have a vehicle decal of size 4 inches * 2 inches.

Further, we need 180 individual stickers.

4 times 3 is 12 on the horizontal axis and 2 times 6 is 12 on the vertical axis. So we can fit 3 columns and 6 rows of our 4*2 size in one square foot. One square foot of sticker material will give us 18 individual labels. And for 180 vehicle decals we need to budget for 10 square feet of the said sticker material.

Please Note: Stickers are not individually produced. They are in fact processed on large sized rolls having 3, 4 and even 5 feet. So please consider a minimum order quantity / M.O.Q. of 10 square feet while calculating your budget

How to Determine the Cost per Sticker of Your Specific Design?

As mentioned above, sticker prices are generally quoted per area of the material, either as a square foot or as a sheet of size 12*18 inches. But both these areas are most probably larger than your small sized sticker.

So how do you figure out the per piece cost of your individual label?

This process involves a little bit of reverse calculation. What we need to do is, figure out how many individual pieces labels fit in an area of 12 inches * 12 inches.

Let’s suppose that we have a vehicle decal of size 2 inches * 2 inches.

So we can fit 6 columns and 6 rows of our 2*2 inch size in one square foot. One square foot of sticker material will give us 36 individual labels.

Please Note: Stickers are not individually produced. They are in fact processed on large sized rolls having 3, 4 and even 5 feet. So please consider a minimum order quantity / M.O.Q. of 10 square feet while calculating your budget

Get a Quote for Stickers

Please leave us your details and we will respond promptly