What is UV Flatbed printing?

Essay which explains UV flatbed printing. A new technology in the print industry. See how to print directly on any flat object by pushing them into the flatbed machine.

Essay which explains UV flatbed printing. A new technology in the print industry. See how to print directly on any flat object by pushing them into the flatbed machine.

Uniquely shaped business cards using laser cutting technology. Guaranteed to make a fabulous first impression.

See how the new white ink UV printing technology can help you create new types of glass film prints for partitions. A different option for branding / decoration your office interiors

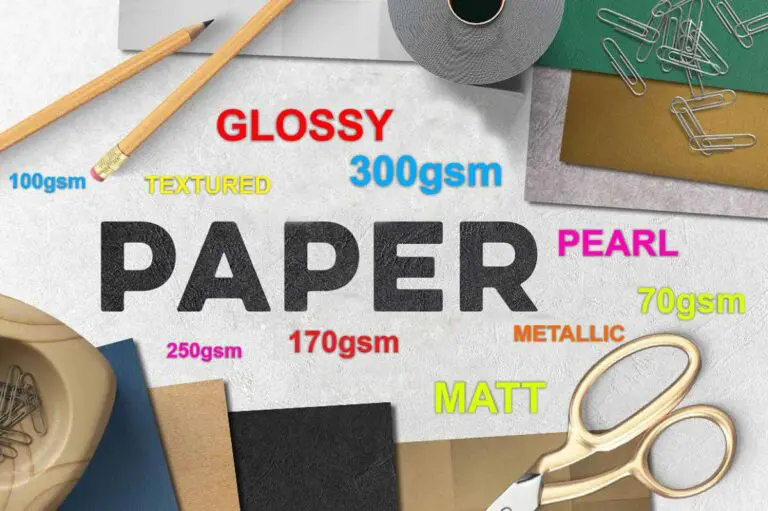

Confused between solvent, eco-solvent & UV inks? Read this comparison to help choose the correct wide format print & inks based on your job requirement.

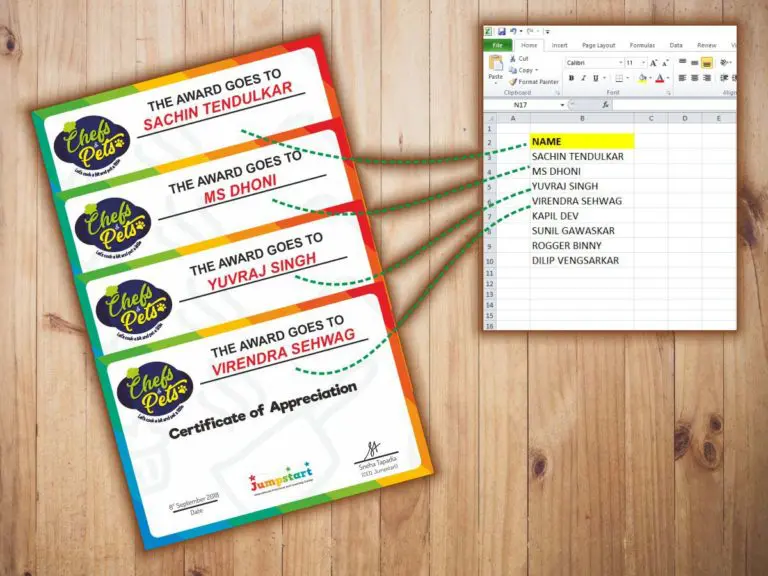

Learn how variable data printing technology can personalise standard template based designs by pulling in data line name, rank, etc. from an independent database.

Pet shops across Pune are branded with product images and logos of the Royal Canin Company. See how we did this.

Case study of how our foam sheet and one way vision prints were installed at multiple retail outlets of the Godrej & Boyce company, in Pune city.

Case study of how backlit shop boards were deployed at virtually every pharmacy in the city to showcase J&J One Touch products

Case study of store branding carried out at beauty salons in Pune. Use of roll-up standees, flex and sunboard prints to highlight the Streax product range.